In the dynamic realm of interior design and architectural aesthetics, materials that combine timeless elegance with modern versatility are highly sought after. Among these, antique mirror wall panels stand out, offering a unique blend of vintage charm and contemporary sophistication. These panels are not merely reflective surfaces; they are artistic statements, capable of transforming any space with their distressed beauty and nuanced reflections. This comprehensive guide delves into the intricate world of antique mirror panels, covering everything from industry trends and technical specifications to their manufacturing process, diverse applications, and the critical factors to consider when selecting a supplier.

The Resurgence of Vintage Elegance: Industry Trends in Antique Mirror Wall Panels

The demand for antique mirror wall panels has witnessed a significant upsurge in recent years, driven by a global shift towards unique, character-filled interiors. Designers and homeowners alike are moving away from sterile, minimalist aesthetics, embracing textures, patterns, and finishes that tell a story. Antique mirrors fit perfectly into this narrative, offering a sense of history and handcrafted artistry.

According to recent market analyses, the global decorative glass market, of which antique mirrors are a significant segment, is projected to grow at a compound annual growth rate (CAGR) of approximately 5-7% over the next five years, indicating a robust and expanding market for specialty glass products. This growth is fueled by increasing urbanization, rising disposable incomes, and a greater emphasis on sophisticated interior décor in both residential and commercial sectors. The trend towards 'speakeasy chic,' 'industrial vintage,' and 'glamorous retro' designs directly contributes to the popularity of antique mirror wall panels, making them a staple in high-end projects.

Technological advancements in glass manufacturing also play a crucial role. Modern techniques allow for a greater variety of antique finishes, from subtle patinas to dramatic distressed effects, catering to diverse design preferences. Furthermore, increased awareness about sustainable building materials and processes is pushing manufacturers to adopt eco-friendlier production methods, enhancing the appeal of such products in an environmentally conscious market.

Understanding the Product: 5mm 6mm Antique Mirror Glass

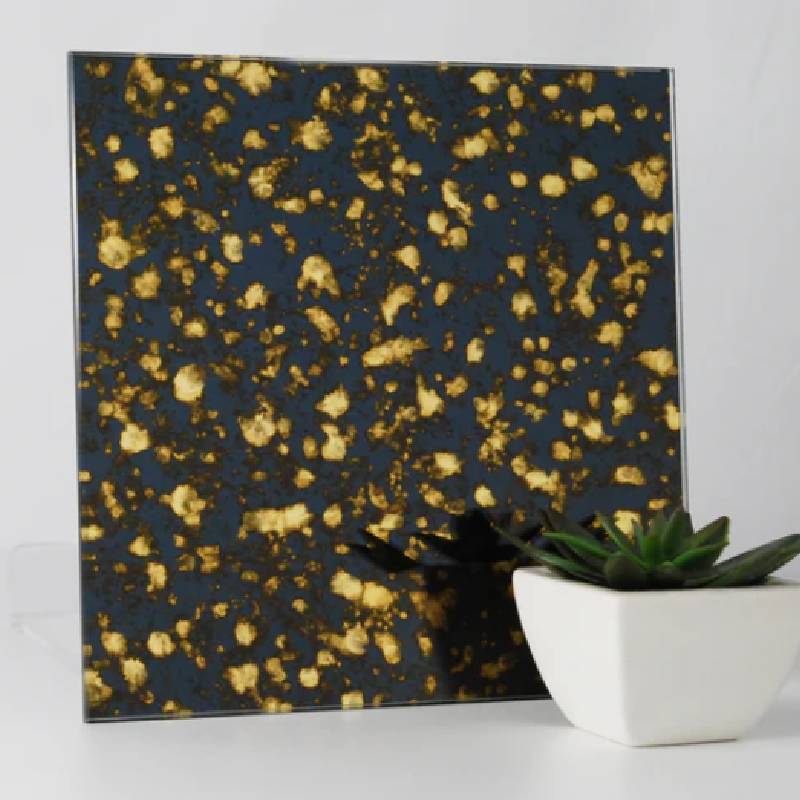

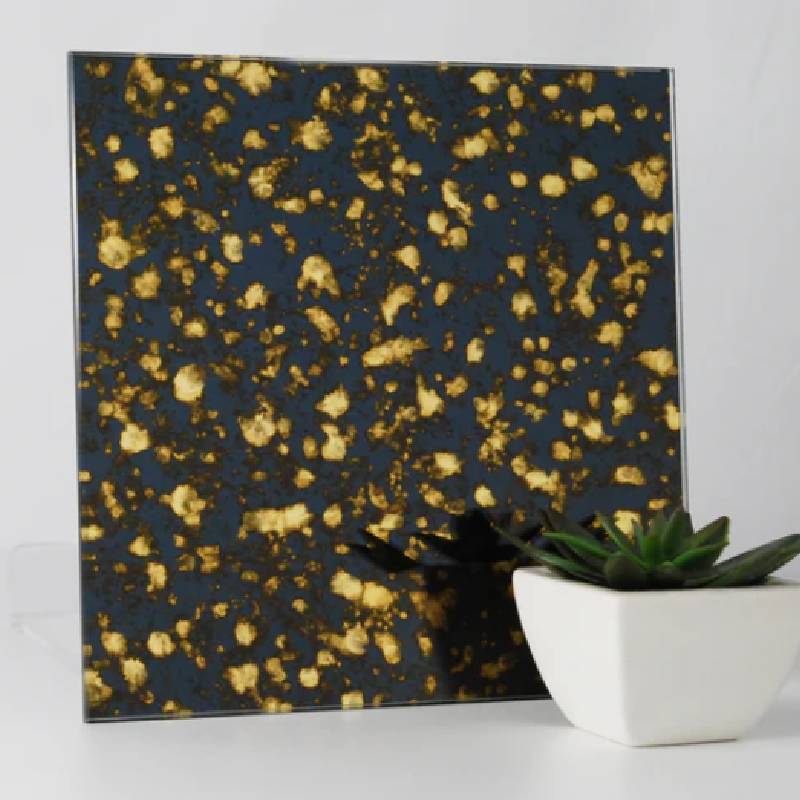

Our flagship product, the 5mm 6mm Antique mirror glass, specifically designed for creating stunning antique mirror wall panels, represents the pinnacle of decorative glass craftsmanship. Unlike standard mirrors, which offer a clear, precise reflection, antique mirrors feature a deliberately aged appearance, characterized by distressed silvering, oxidized patterns, and a soft, diffused reflection. This effect creates a unique ambiance, adding depth, texture, and a sense of timeless elegance to any space.

Technical Parameters and Specifications

The quality and performance of antique mirror wall panels are defined by precise technical specifications. Our 5mm and 6mm thick antique mirror glass sheets are engineered to meet stringent industry standards, ensuring both aesthetic appeal and structural integrity. Below is a detailed table outlining key parameters:

| Parameter |

Specification |

Description / Benefit |

| Product Name |

5mm 6mm Antique mirror glass |

Core product for antique mirror wall panels. |

| Thickness |

5mm, 6mm |

Optimal thickness for durability, ease of installation, and structural integrity in wall applications. 5mm offers versatility, 6mm provides enhanced robustness. |

| Standard Sizes |

1830x2440mm, 2134x3300mm, 2134x3660mm (Custom sizes available) |

Common sheet sizes minimizing waste and facilitating large installations. |

| Base Material |

High-quality Clear Float Glass (Conforms to ASTM C1036) |

Ensures optical clarity before the antiquing process, providing a smooth, distortion-free substrate. |

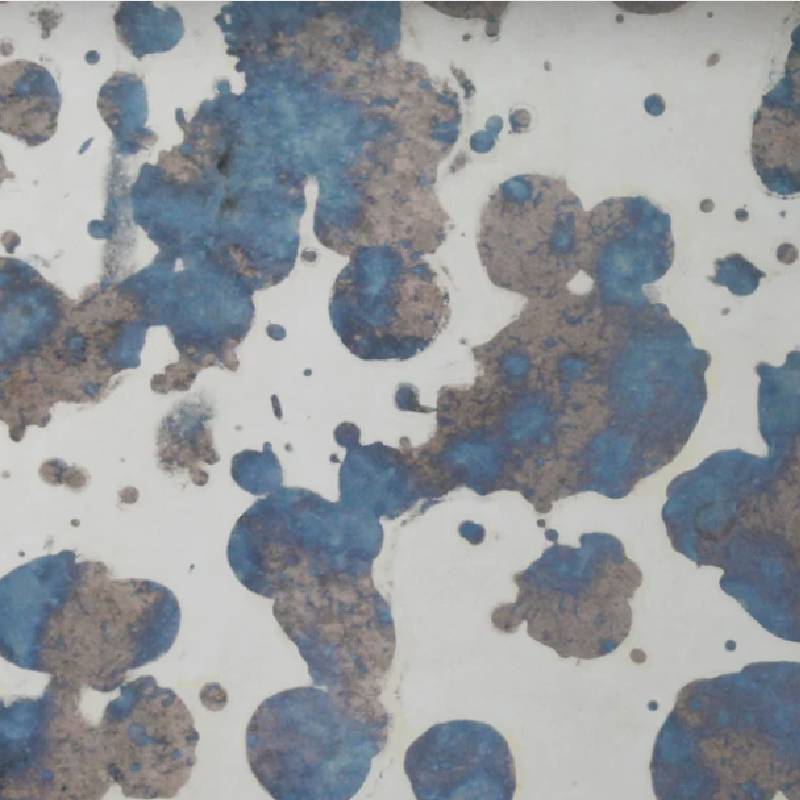

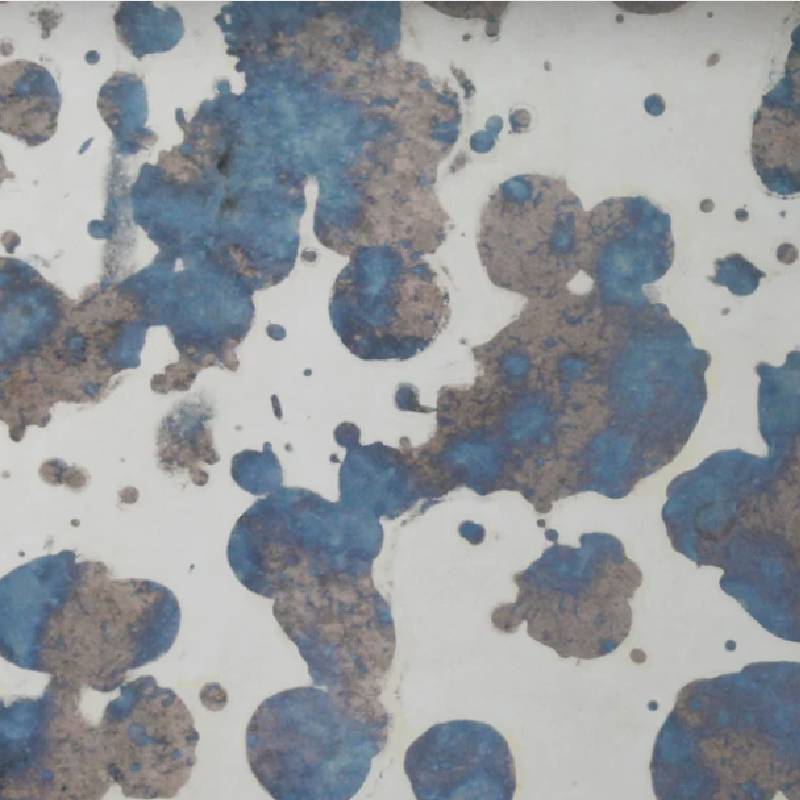

| Antiquing Patterns |

Over 30 distinct patterns (e.g., Venetian, Galaxy, Linear, Mottled, Crackled, Oxidized, Speckled) |

Wide range of aesthetic choices to match diverse design themes and create unique visual effects. Each pattern is meticulously developed. |

| Backing Paint |

Fenzi paint (Italy) or equal lead-free paint, double coated |

Superior protection against moisture and corrosion, significantly extending the mirror's lifespan. Ensures environmental safety (lead-free). |

| Reflectivity |

Reduced reflectivity (approx. 60-70%) compared to clear mirrors |

Achieves a softer, diffused reflection, ideal for creating ambiance without harsh glares, enhancing the "aged" aesthetic. |

| Edge Work Options |

Polished edge, Beveled edge, Arris edge |

Customizable finishes for aesthetics and safety during installation. |

| Environmental Compliance |

RoHS compliant, Lead-Free |

Adheres to international environmental standards, making it safe for indoor environments. |

| Warranty |

5-10 years (depending on application and maintenance) |

Commitment to product quality and longevity under proper care. |

The meticulous selection of raw materials, such as high-quality clear float glass conforming to standards like ASTM C1036 (Standard Specification for Flat Glass), ensures that the foundation of our antique mirror wall panels is of superior clarity and structural integrity. The use of premium, lead-free backing paint (like Fenzi paint from Italy) is critical for durability, preventing oxidation and de-silvering over time, thereby significantly extending the product's lifespan and maintaining its aesthetic appeal in various environmental conditions.

The Art and Science of Manufacturing: Process Flow for Antique Mirror Wall Panels

The creation of antique mirror wall panels is a sophisticated process that combines traditional craftsmanship with modern technology. It involves a series of precise steps to transform standard float glass into a unique piece of art. Our manufacturing process adheres to strict quality control protocols, including ISO 9001 certification for quality management systems, ensuring consistency and excellence in every panel. While a visual diagram or short video would best illustrate this, here’s a detailed explanation of the key stages:

1. Glass Cutting & Edge Work

High-quality clear float glass sheets are precisely cut to the required dimensions using advanced CNC cutting machines. This ensures accurate sizing and minimizes material waste. Following cutting, edges are processed (polished, beveled, or arris) based on client specifications, enhancing safety and aesthetic finish.

2. Multi-Stage Cleaning

The cut glass is rigorously cleaned in multiple stages using de-ionized water and specialized cleaning agents. This crucial step removes all impurities, dust, and contaminants from the glass surface, which are essential for proper adhesion of the silvering solution and preventing defects.

3. Sensitizing & Silvering

The clean glass surface is sensitized with a tin chloride solution, preparing it for the silvering process. This is followed by spraying a uniform layer of silver nitrate solution, which reacts chemically to deposit a metallic silver layer onto the glass, forming the reflective surface. This process is carefully controlled for thickness and uniformity.

4. Copper Coating (Optional, for enhanced durability)

For enhanced durability and corrosion resistance, a protective layer of copper is often applied over the silver. This acts as a barrier, preventing oxidation of the silver layer and providing a stable base for the subsequent paint coating.

5. Antiquing Treatment (Distressing)

This is the artistic core of the process. A specialized chemical solution is applied to the silver or copper layer, carefully controlled to create various distressed effects. This solution selectively corrodes and oxidizes the metallic layers, producing unique patterns, spots, and streaks that mimic the natural aging process of antique mirrors. Precision and timing are key here to achieve the desired patina.

6. Backing Paint Application

After the antiquing treatment, a double layer of high-quality, lead-free backing paint (e.g., Fenzi paint) is applied to protect the silvering and antiqued layers from moisture, scratches, and chemical damage. The first layer is typically a base coat, followed by a protective topcoat, ensuring long-term durability and stability.

7. Curing & Drying

The painted glass panels are then passed through a curing oven where the backing paint is heat-treated to ensure proper adhesion, hardness, and chemical resistance. This step is vital for the longevity of the mirror's reflective and distressed surfaces.

8. Final Inspection & Packaging

Each antique mirror wall panel undergoes a thorough final inspection for quality, pattern consistency, absence of defects, and adherence to specified dimensions. Panels are then carefully packaged using protective materials (e.g., wooden crates, interleave paper, corner protection) to prevent damage during transit, ready for global shipment.

Our commitment to quality extends to every stage, with in-line and final inspections ensuring that each antique mirror wall panel meets rigorous performance and aesthetic standards, including relevant sections of ANSI Z97.1 (Safety Glazing Materials Used in Buildings - Safety Performance Specifications and Methods of Test) where applicable for safety considerations.

Beyond Reflection: Applications and Advantages of Antique Mirror Wall Panels

Antique mirror wall panels are celebrated for their transformative power in diverse environments. Their unique aesthetic offers a versatile design element, moving beyond the traditional function of a mirror to become a focal point, an accent, or a subtle backdrop. Their inherent advantages make them ideal for various applications across residential, commercial, and hospitality sectors.

Diverse Application Scenarios:

- Residential Interiors: Perfect for living rooms, dining areas, bedrooms, and bathrooms. They can serve as decorative backsplashes, feature walls, closet doors, or furniture inserts, adding depth and character without overwhelming the space. In smaller rooms, they can create an illusion of greater space while introducing visual interest.

- Commercial Spaces: High-end retail stores, boutiques, and showrooms use antique mirror wall panels to create sophisticated backdrops, display cases, or decorative elements that enhance brand image and customer experience. Their ability to diffuse light creates a warm, inviting atmosphere.

- Hospitality Industry: Luxury hotels, restaurants, bars, and cafes frequently incorporate antique mirrors. They are utilized in lobbies, dining areas, bar fronts, and even guest rooms to evoke a sense of grandeur, history, and bespoke luxury. The subtle reflections enhance ambient lighting, contributing to a cozy and upscale atmosphere.

- Historical Restorations & Period Properties: In projects requiring authenticity and a nod to historical aesthetics, antique mirrors provide the perfect aged look, seamlessly blending with existing architectural elements.

- Furniture & Cabinetry: Antique mirror inserts can elevate the design of cabinets, wardrobes, tables, and headboards, adding a touch of vintage glamour to bespoke furniture pieces.

Key Technical Advantages:

While often chosen for their aesthetic appeal, antique mirror wall panels also offer significant functional benefits:

- Enhanced Aesthetic Versatility: With over 30 unique patterns, they offer unparalleled design flexibility, allowing for personalized artistic expressions that cannot be replicated by standard mirrors. They can complement both traditional and contemporary design schemes.

- Soft, Diffused Reflection: Unlike conventional mirrors that can create harsh glares, antique mirrors provide a softer, more diffused reflection. This characteristic is ideal for creating intimate, warm, and inviting environments, enhancing natural light without creating overly bright spots.

- Durability and Longevity: Thanks to the multi-layered backing paint and robust manufacturing process (including potential copper coating), our antique mirror wall panels exhibit excellent resistance to moisture, corrosion, and common household chemicals. This ensures their beauty and reflective quality are preserved for years, even in high-humidity areas like bathrooms or kitchens.

- Illusion of Space & Depth: While their reflection is softened, antique mirrors still possess the ability to expand a space visually, making rooms feel larger and more open. The aged patterns add an extra layer of depth and visual interest, creating dynamic focal points.

- Masking Imperfections: The distressed patterns naturally help to obscure minor dust, fingerprints, or minor surface imperfections, making them relatively low-maintenance compared to perfectly clear mirrors.

- UV Resistance: The protective layers contribute to UV resistance, helping to prevent fading or degradation of the mirror's appearance over time, especially in areas exposed to natural light.

Our panels are also engineered to meet relevant safety standards, such as those for interior architectural glass, ensuring they are not only beautiful but also safe for public and private spaces.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

Selecting the right manufacturer for your antique mirror wall panels is paramount to the success of your project. The market offers various suppliers, but discerning quality, consistency, and reliability requires careful consideration. Our company distinguishes itself through a blend of extensive experience, advanced manufacturing capabilities, and a customer-centric approach.

Key Criteria for Manufacturer Comparison:

- Experience & Expertise: Look for manufacturers with a proven track record and deep understanding of glass processing and antique mirror production. Expertise ensures consistent quality and innovative solutions.

- Quality Control & Certifications: Verify adherence to international quality standards (e.g., ISO 9001) and product-specific certifications (e.g., ASTM standards for glass, RoHS compliance for materials).

- Customization Capabilities: A good supplier should offer extensive customization options, including bespoke sizes, unique patterns, edge work, and safety backing.

- Production Lead Times & Delivery: Assess their capacity to meet your project timelines and their logistics capabilities for safe, timely delivery globally.

- Customer Support & After-Sales Service: Evaluate their responsiveness, technical support, and warranty policies.

Why Choose Us for Your Antique Mirror Wall Panels:

| Feature |

Our Company (SHZR Glass) |

Typical Competitor A |

Typical Competitor B |

| Industry Experience |

20+ Years specializing in decorative glass & mirrors |

5-10 Years (General glass) |

10-15 Years (Mixed products) |

| Product Range |

5mm, 6mm Antique mirror wall panels (30+ patterns), extensive decorative glass |

Limited patterns (5-10), focus on standard mirrors |

Decent range (15-20 patterns), variable quality |

| Quality Certifications |

ISO 9001, RoHS, CE, ASTM compliant materials |

Basic ISO, limited product-specific certs |

Some regional certs |

| Customization |

Full bespoke capabilities (size, pattern, edge, safety backing) |

Limited custom sizes, fixed patterns |

Moderate customization options |

| Lead-Free Materials |

Yes (Fenzi paint or equal) |

Often uses standard paints |

May vary by batch |

| Global Delivery |

Robust logistics network, safe packaging |

Primarily domestic or regional |

Developing international shipping |

| Warranty & Support |

5-10 year warranty, dedicated account managers |

1-3 year limited warranty |

Case-by-case support |

Custom Solutions: Tailored to Your Vision

We understand that every design project is unique. Our approach to antique mirror wall panels is highly collaborative, offering comprehensive customization solutions:

- Bespoke Dimensions: From small accent pieces to large-scale wall cladding, we cut panels to your exact specifications.

- Unique Patterns & Finishes: While we offer over 30 standard patterns, our R&D team can work with designers to develop exclusive, custom antique effects that perfectly align with a specific aesthetic vision.

- Edge Work Perfection: Choose from various edge finishes – polished for a sleek look, beveled for added dimensionality, or arris for practical safety – all executed with precision.

- Safety Backing Options: For enhanced safety and compliance, especially in public spaces, we offer safety backing (e.g., CAT I or CAT II film) that prevents glass shards from scattering in case of breakage.

- Installation Support: While we provide the panels, we also offer technical guidance and recommendations for secure and aesthetically pleasing installation.

Realizing Vision: Application Cases and Client Experience

The true testament to the versatility and transformative power of antique mirror wall panels lies in their successful application across various prestigious projects. Our extensive experience has allowed us to collaborate with leading architects, interior designers, and contractors worldwide, bringing their most ambitious visions to life.

Case Study 1: The Grandeur Hotel Lobby Renovation (New York, USA)

Challenge: To revitalize a classic hotel lobby with a design that honored its historical roots while embracing modern luxury, creating a sense of arrival and sophisticated warmth.

Solution: We supplied large-format 6mm antique mirror wall panels with a custom "Venetian Aged" pattern for a prominent feature wall behind the reception desk and along the main corridors. The subtle patina and diffused reflections beautifully complemented the ornate chandeliers and marble flooring, creating a luminous yet inviting atmosphere. The panels were specifically chosen for their durability and ease of maintenance in a high-traffic area.

Client Feedback: "The antique mirror panels from SHZR Glass were the perfect choice. They added an incredible depth and character to the lobby, garnering numerous compliments from guests and reviewers. The quality and installation support were exceptional, truly a partnership." - *Sarah Chen, Lead Designer, Elite Hospitality Design Group.*

Case Study 2: Boutique Retail Store Façade (London, UK)

Challenge: A high-end fashion boutique sought a unique storefront that would stand out on a bustling street, attracting discerning clientele while subtly reflecting the brand's sophisticated aesthetic.

Solution: Custom 5mm antique mirror wall panels with a "Smoky Crackle" pattern were fabricated and installed as a prominent element of the exterior facade and interior display niches. The panels offered a captivating, ever-changing reflection of the streetscape, subtly inviting passersby. Their robust backing paint provided excellent weather resistance, critical for an exterior application.

Client Feedback: "We wanted something truly unique, and the antique mirrors delivered. They've become a landmark on the street, drawing people in. The team's attention to detail, from pattern selection to delivery, was flawless." - *David Green, Owner, Lumina Fashion House.*

Case Study 3: Private Residential Project – Luxury Penthouse (Dubai, UAE)

Challenge: To infuse a modern penthouse with warmth, character, and a sense of timeless luxury, specifically in the living and dining areas.

Solution: We provided bespoke 6mm antique mirror wall panels with a "Mottled Gold" finish for a large feature wall in the living room and as a decorative backsplash in the open-plan kitchen. The panels' warm tones and unique distressing created a rich, inviting ambiance, enhancing the natural light and views without creating harsh reflections. The durability and ease of cleaning were particularly appreciated for the kitchen application.

Client Feedback: "The antique mirrors are simply breathtaking. They add an unparalleled elegance and depth to our home. Every guest comments on them. The custom fit and finish are superb." - *Ms. Al-Farsi, Private Client.*

These case studies underscore our expertise in delivering high-quality, customized antique mirror wall panels that meet the diverse and exacting requirements of global projects, reflecting our commitment to excellence and client satisfaction.

Ensuring Trustworthiness: Our Commitment to Quality and Support

At SHZR Glass, building trust is at the core of our operations. We adhere to the highest standards of transparency, quality assurance, and customer service, ensuring that every client feels confident in their investment in our antique mirror wall panels.

Quality Assurance & Certifications:

Our commitment to quality is validated by our adherence to international standards. We operate under an ISO 9001 certified quality management system, overseeing every stage from raw material procurement to final inspection. Our products are tested to meet or exceed industry benchmarks for durability, reflectivity, and aesthetic consistency. Materials used, such as our lead-free Fenzi backing paint, ensure environmental safety and product longevity. Where applicable for specific applications, our glass can conform to safety glazing standards such as ANSI Z97.1 and CE marking for European markets, ensuring broad applicability and compliance.

Transparent Delivery Cycle:

We understand the importance of timely delivery for project success. Our typical delivery cycle for antique mirror wall panels is outlined as follows:

- Order Confirmation & Production Planning: 2-3 business days

- Manufacturing Lead Time: 15-25 business days (depending on volume, complexity of customization, and current production schedule)

- Quality Inspection & Packaging: 3-5 business days

- Shipping (Ocean Freight): 20-45 days (depending on destination, customs, and shipping line schedules)

- Shipping (Air Freight): 5-10 days (for urgent, smaller orders)

We provide real-time updates and dedicated logistics support to track your order from our factory to your doorstep, minimizing delays and ensuring safe arrival.

Comprehensive Warranty & Customer Support:

We stand behind the quality of our antique mirror wall panels with a robust warranty. Our 5mm and 6mm antique mirror glass is covered by a 5-year limited warranty against manufacturing defects and de-silvering under normal use and proper installation. For select applications and with proper maintenance, the effective lifespan and aesthetic integrity can extend significantly, often exceeding 10 years.

Our dedicated customer support team is available to assist with any inquiries, from product selection and technical specifications to order tracking and after-sales service. We believe in building long-term relationships through reliable products and exceptional support.

Frequently Asked Questions (FAQ) about Antique Mirror Wall Panels

Q1: What is the primary difference between antique mirror and regular mirror?

A1: The primary difference lies in their aesthetic. A regular mirror provides a clear, precise reflection. An antique mirror wall panel undergoes a special distressing process during manufacturing, resulting in a deliberately aged, patinated, or oxidized appearance with a softer, diffused reflection. This gives it a vintage, historical, or rustic charm, rather than perfect clarity.

Q2: What thickness options are available for your antique mirror glass?

A2: We primarily offer 5mm and 6mm thickness options for our antique mirror wall panels. These thicknesses provide an optimal balance of durability, stability for large panels, and ease of handling and installation across various applications.

Q3: Can antique mirror wall panels be used in high-humidity areas like bathrooms?

A3: Yes, our antique mirror wall panels are designed with high-quality, moisture-resistant backing paint (such as Fenzi paint) that significantly protects the silvering from oxidation and corrosion. This makes them suitable for use in bathrooms, powder rooms, and other areas with elevated humidity, provided proper ventilation and installation methods are followed.

Q4: How do I clean and maintain antique mirror wall panels?

A4: For cleaning, use a soft, lint-free cloth with a mild, non-abrasive glass cleaner that is ammonia-free. Spray the cleaner onto the cloth first, not directly onto the mirror, to prevent liquid from seeping behind the glass. Avoid harsh chemicals or abrasive materials that could damage the antique finish or backing paint. Regular, gentle cleaning will maintain their beauty.

Q5: Are custom patterns and sizes available for antique mirror panels?

A5: Absolutely. We offer extensive customization options. In addition to our range of over 30 standard antique patterns, we can develop bespoke patterns to match specific design requirements. We also custom-cut antique mirror wall panels to virtually any dimension required for your project, from small inserts to large architectural installations.

Q6: What safety standards do your antique mirrors meet?

A6: Our base clear float glass adheres to standards like ASTM C1036. While antique mirrors are primarily decorative and typically not used as primary safety glazing, for applications where enhanced safety is a concern, we can apply safety backing (e.g., CAT II film) to the panels. This film helps to hold glass fragments together if breakage occurs, reducing injury risk. All materials used are RoHS compliant and lead-free.

Q7: What is the typical lead time for an order of antique mirror wall panels?

A7: Production lead time typically ranges from 15 to 25 business days, depending on the order size, pattern complexity, and current factory schedule. Shipping time will vary based on the destination and chosen freight method (e.g., 20-45 days for ocean freight). We provide clear timelines upon order confirmation and strive for efficient delivery.

Further Reading & Industry Insights

For those interested in delving deeper into the nuances of glass technology, interior design trends, and the specifics of mirror manufacturing, we recommend exploring the following resources:

- Architectural Record Magazine: "The Resurgence of Specialty Glass in Modern Design" - Discusses how unique glass products, including decorative mirrors, are shaping contemporary architecture. www.architecturalrecord.com/articles/specialty-glass-trends

- Glass Magazine: "Advanced Techniques in Mirror Manufacturing: Achieving Aesthetic Longevity" - Explores the chemical processes and quality controls behind durable mirror production. www.glassmagazine.com/articles/mirror-manufacturing-longevity

- International Interior Design Association (IIDA) Journal: "Integrating Vintage Elements: A Guide for Contemporary Interiors" - Offers perspectives on incorporating antique and distressed finishes into modern spaces. www.iida.org/journal/vintage-design

- ASTM International (American Society for Testing and Materials): Provides comprehensive standards for glass and glazing, including ASTM C1503 - Standard Specification for Silvered Flat Glass Mirror. www.astm.org/standards/c1503

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu