Авг . 24, 2025 00:40

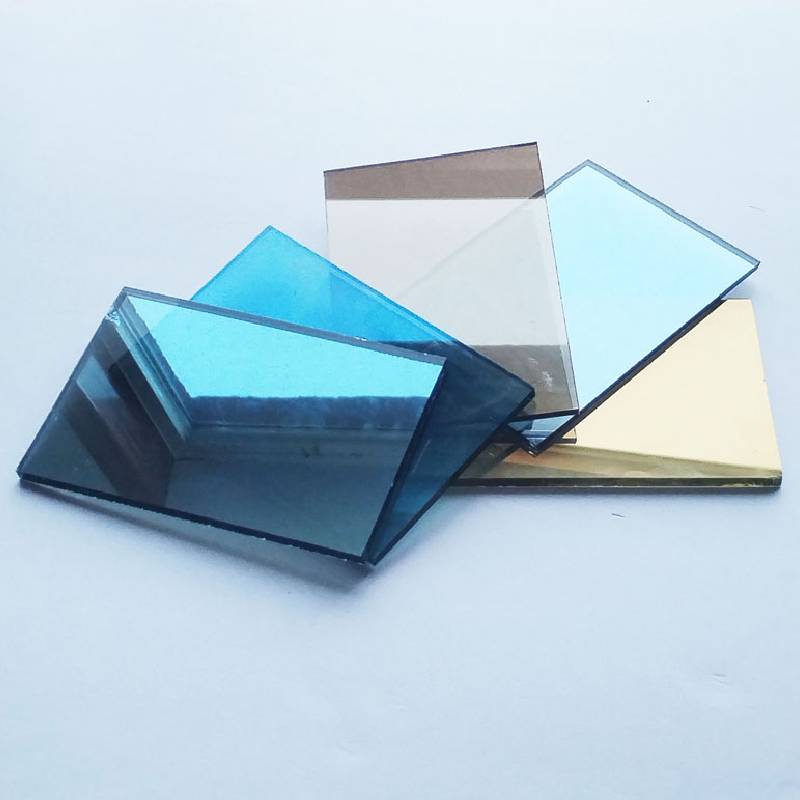

In the rapidly evolving landscape of modern construction and architectural design, the demand for high-performance building materials that offer both aesthetic appeal and superior functional benefits is paramount. Among these, reflective glass stands out as a critical component. This advanced glazing technology is engineered to control solar radiation, enhance energy efficiency, and provide privacy, making it an indispensable choice for contemporary facades, windows, and curtain walls.

Our focus today is on the intricate details of this material, particularly the 5mm reflective glass dark green reflective glass, exploring its manufacturing nuances, technical prowess, diverse applications, and the significant advantages it offers across various industrial sectors. From reducing cooling loads in commercial skyscrapers to improving thermal comfort in residential settings, this specialized glass plays a pivotal role in sustainable building practices.

The market for reflective glass is experiencing robust growth, driven by an increasing global emphasis on energy conservation and sustainable architecture. Key trends include:

These trends underscore the importance of selecting a high-quality, technically sound product, whether it's for a monumental facade or a residential black reflective glass window application.

The production of reflective glass is a sophisticated multi-stage process, blending traditional glass manufacturing with advanced coating technologies. This ensures the desired optical and thermal properties. The primary product materials include high-quality silica sand, soda ash, limestone, dolomite, and metallic oxides for the reflective coating.

Raw materials are melted in a furnace at approximately 1600°C. The molten glass is then continuously poured onto a bed of molten tin, where it spreads and forms a flat ribbon with uniform thickness and a naturally polished surface. This casting process is critical for the foundational glass quality.

This is the defining stage for achieving the desired properties. Two main methods are employed:

The coated glass ribbon passes through an annealing lehr, where it is gradually cooled to room temperature. This controlled cooling process removes internal stresses, enhancing the glass's strength and preventing breakage. Further CNC machining might be applied post-annealing for precision cutting and shaping.

The continuous glass ribbon is cut into desired sizes and shapes. Each piece undergoes stringent quality control, adhering to international testing standards such as ISO 9001 for quality management, ASTM E2188 for optical properties, and EN 1096 for coated glass. This ensures parameters like 5mm reflective glass thickness and coating consistency meet specifications.

Target Industries & Advantages: The superior energy-saving properties and corrosion resistance of well-manufactured glass make it ideal for industries such as petrochemical (for specific containment needs), metallurgy (heat management), and construction (energy-efficient facades). Its service life typically exceeds 15-20 years, depending on environmental conditions and coating type.

Understanding the technical specifications of reflective glass is crucial for architects, engineers, and procurement professionals. We will detail parameters for a typical 5mm reflective glass dark green reflective glass, along with a comparative analysis of other variants.

| Parameter | Value for 5mm Dark Green Reflective Glass |

|---|---|

| Nominal Thickness | 5mm (±0.2mm) |

| Visible Light Transmittance (VLT) | 8% - 12% (Typical) |

| Solar Heat Gain Coefficient (SHGC) | 0.20 - 0.25 (Typical) |

| U-value (Single Glazing) | 5.7 W/(m²·K) |

| UV Rejection | > 70% |

| External Reflectance (Visible) | 30% - 40% |

| Standard Sizes | 2134x3300mm, 2440x3300mm, 2440x3660mm (Custom available) |

| Compliance Standards | ISO 9001, ASTM E2188, EN 1096-1 |

| Type | VLT (%) | SHGC | External Reflectance (%) | Typical Price Range (per SqM) |

|---|---|---|---|---|

| Dark Green Reflective Glass | 8-12 | 0.20-0.25 | 30-40 | Competitive 5mm reflective glass price |

| Blue Reflective Glass | 10-15 | 0.22-0.28 | 25-35 | Mid-range blue reflective glass price |

| Bronze Reflective Glass | 15-20 | 0.28-0.35 | 20-30 | Economical |

| Black Reflective Glass | 5-10 | 0.18-0.22 | 35-45 | Premium |

These figures are indicative and can vary based on specific manufacturing processes and coating formulations. Always refer to certified product data sheets for precise project specifications.

The strategic implementation of reflective glass in architectural projects yields numerous technical and operational benefits, making it a preferred choice for modern building envelopes.

The versatility and high-performance attributes of reflective glass enable its broad application across various sectors, addressing distinct functional and aesthetic requirements.

Choosing the right supplier for reflective glass is a critical decision that impacts project success, cost, and long-term performance. Prospective buyers should evaluate vendors based on several key criteria:

Choosing a vendor that excels in these areas ensures a smooth procurement process and a high-quality end product that performs as expected.

While standard reflective glass products cater to many needs, specialized architectural projects often demand bespoke solutions. Leading manufacturers offer comprehensive customization options to meet unique aesthetic, performance, and structural requirements.

Engaging with a manufacturer early in the design phase allows for collaborative development of bespoke glass solutions that integrate seamlessly with project goals, ensuring optimal performance and aesthetic realization.

Our commitment to delivering high-performance glazing solutions is validated by successful project implementations across diverse sectors. These case studies highlight the tangible benefits achieved by our clients.

A 30-story office tower located in a hot, humid climate sought to significantly reduce its reliance on air conditioning and improve occupant comfort. We provided a custom solution using 5mm reflective glass dark green reflective glass in an insulated glass unit configuration. The specified glass featured an SHGC of 0.22 and a VLT of 10%. The dark green tint also provided a distinctive aesthetic that blended with the urban landscape.

Outcome: Post-occupancy evaluations revealed a 28% reduction in annual cooling energy consumption compared to initial projections with standard glazing. Occupant feedback consistently highlighted reduced glare and a more stable indoor temperature, contributing to enhanced productivity. The building received a LEED Gold certification, partly due to the high-performance facade.

A luxury boutique hotel required a facade that offered both superior solar control and a unique, modern aesthetic to stand out in a competitive urban environment. We collaborated with the architects to supply a specialized black reflective glass solution. The choice of black reflective glass window units created a sophisticated, monolithic appearance while ensuring maximum daytime privacy for guests and exceptional solar performance with an SHGC of 0.19 and VLT of 7%.

Outcome: The hotel achieved its design vision, receiving widespread acclaim for its striking exterior. The high reflectance of the black glass also effectively managed heat gain, contributing to a premium guest experience with comfortable room temperatures and minimal energy expenditure for climate control. The project demonstrated that aesthetic goals can be achieved without compromising thermal performance.

A large residential development in a region known for intense sunlight and high UV exposure required glazing that protected interiors and improved living comfort. We supplied laminated blue reflective glass for all exterior windows and patio doors. The blue tint provided a pleasant, cool aesthetic, and the lamination added enhanced safety and UV protection (>99% blocked), crucial for preserving valuable furnishings.

Outcome: Residents reported significantly cooler indoor temperatures, particularly during peak summer months, and noticeable reductions in glare. The added UV protection ensured that furniture and flooring maintained their original color and integrity over time. The competitive blue reflective glass price for a laminated product also provided excellent value for the developer.

Our commitment extends beyond delivering superior glass products; we prioritize establishing long-term trust and providing comprehensive support to our clients.

A: With proper installation and maintenance, high-quality reflective glass, especially hard-coat (pyrolytic) types, can have a service life exceeding 15-20 years. Soft-coat (vacuum deposited) glass often lasts as long when protected within an Insulated Glass Unit (IGU).

Q2: How does this glass contribute to energy savings?A: It significantly reduces solar heat gain by reflecting a large portion of the sun's energy, thereby lowering the demand on air conditioning systems. This leads to substantial energy cost reductions, particularly in warmer climates.

Q3: Can 5mm reflective glass be tempered or laminated?A: Yes, most reflective glass types, including 5mm reflective glass, can be further processed into tempered glass for safety or laminated glass for enhanced security and acoustic performance. This customization ensures suitability for diverse applications.

Q4: What is the difference between pyrolytic and vacuum-deposited reflective coatings?A: Pyrolytic (hard coat) is applied during the float process, resulting in a durable, scratch-resistant coating. Vacuum-deposited (soft coat) is applied offline in a vacuum chamber, offering greater optical precision but requiring protection (e.g., within an IGU) due to its softer nature.

Our typical lead time for standard sizes and colors of glass (e.g., 5mm reflective glass dark green reflective glass) is 2-3 weeks from order confirmation. Custom orders, including specific dimensions, unique colors, or specialized processing (lamination, tempering), may require 4-6 weeks. We maintain robust supply chain management to ensure timely and efficient delivery, supporting your project timelines.

We stand by the quality of our products. All our specialized glass products come with a comprehensive warranty against manufacturing defects, typically ranging from 5 to 10 years, depending on the product type and application. Specific warranty details are provided with each quotation and order confirmation, ensuring peace of mind regarding your investment.

Our dedicated customer support team is available to assist you from project inception to post-installation. For technical inquiries, project consultations, or after-sales service, please contact us via:

We are committed to providing responsive, expert support to ensure your complete satisfaction with our glazing solutions.

The strategic application of advanced glazing, particularly high-performance variants like 5mm reflective glass dark green reflective glass, is fundamental to achieving sustainable, energy-efficient, and aesthetically compelling architectural designs. By leveraging superior solar control, UV protection, enhanced privacy, and a wide range of customization options, reflective glass empowers architects and builders to create structures that are not only visually impressive but also environmentally responsible and cost-effective over their operational lifespan. Partnering with a knowledgeable and experienced supplier ensures access to high-quality products and expert support, critical for realizing the full potential of this versatile material.

Ultra Clear Low Iron Glass: High Light Transmission Solutions

NewsAug.28,2025

Unveiling Tempered Glass: The Invisible Armor Guarding Your Modern Life

NewsAug.27,2025

Revolutionizing Modern Architecture with Patterned Solar Glass

NewsAug.22,2025

Low Iron Glazing Elevates Modern Architectural Standards

NewsAug.22,2025

Premium Glass Gaming Mousepad Elevate Your Gaming Experience

NewsAug.22,2025

Acid Etching Glass at Home A Guide to Custom Creations

NewsAug.22,2025