The Versatility and Precision of Nashiji Obscure Pattern Glass

In contemporary architecture and interior design, the demand for materials that offer both aesthetic appeal and functional performance is paramount. Among these, 3mm 4mm Nashiji obscure pattern glass stands out as a superior choice, providing an optimal balance of privacy, light transmission, and decorative elegance. This specialized glass, characterized by its distinctive 'Nashiji' (pear skin) texture, diffuses light effectively while maintaining visual obscurity, making it ideal for a wide array of B2B applications where both form and function are critical. Its precise manufacturing and inherent durability meet the stringent requirements of various industries, from commercial building facades to sophisticated interior partitions.

The following sections delve into the intricate details of this high-performance material, covering its manufacturing process, technical specifications, diverse applications, and the competitive advantages it offers to businesses seeking reliable and visually appealing glass solutions.

Industry Trends in Obscure Pattern Glass

The market for architectural and specialty glass is constantly evolving, driven by innovations in material science, aesthetic preferences, and sustainability goals. Current industry trends highlight a growing demand for obscure and patterned glass, largely due to its ability to address multiple design and functional requirements simultaneously. Privacy, while allowing natural light, remains a core need in both commercial and residential sectors. Furthermore, patterned glass like 3mm 4mm Nashiji obscure pattern glass is increasingly favored for its decorative qualities, adding texture and visual interest to spaces without the need for additional ornamentation.

Key trends include:

- Enhanced Privacy and Light Diffusion: Modern office environments and public spaces prioritize privacy without sacrificing natural light. Obscure glass effectively diffuses light, reducing glare and creating a softer, more evenly lit interior, contributing to occupant comfort and energy efficiency by minimizing reliance on artificial lighting during daylight hours.

- Aesthetic Versatility: Designers are moving towards materials that offer both utility and beauty. The unique 'Nashiji' texture provides a subtle yet distinct aesthetic that complements a wide range of interior styles, from minimalist to industrial.

- Sustainability and Energy Efficiency: While not primarily an insulating glass, the light-diffusing properties of patterned glass can indirectly contribute to energy savings by reducing direct solar heat gain and improving daylighting, thereby lessening the load on HVAC systems and artificial lighting.

- Health and Well-being: Access to natural light is crucial for human well-being. Obscure glass provides this benefit while shielding occupants from harsh direct sunlight and maintaining visual privacy, fostering more comfortable and productive environments.

These trends underscore the strategic importance of products like Nashiji pattern glass in meeting the evolving needs of the B2B market, offering solutions that are both practical and visually compelling.

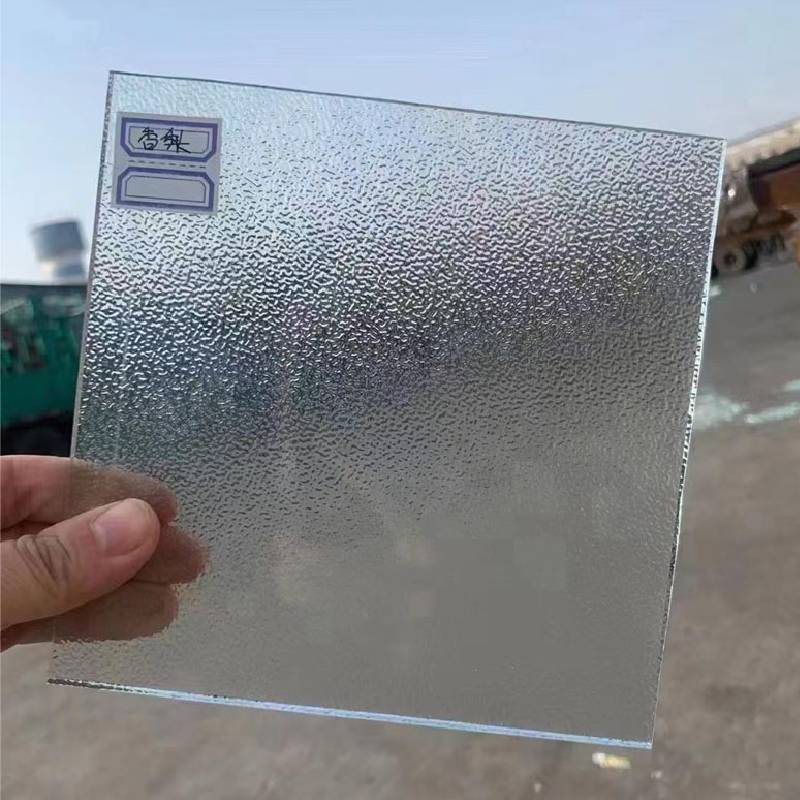

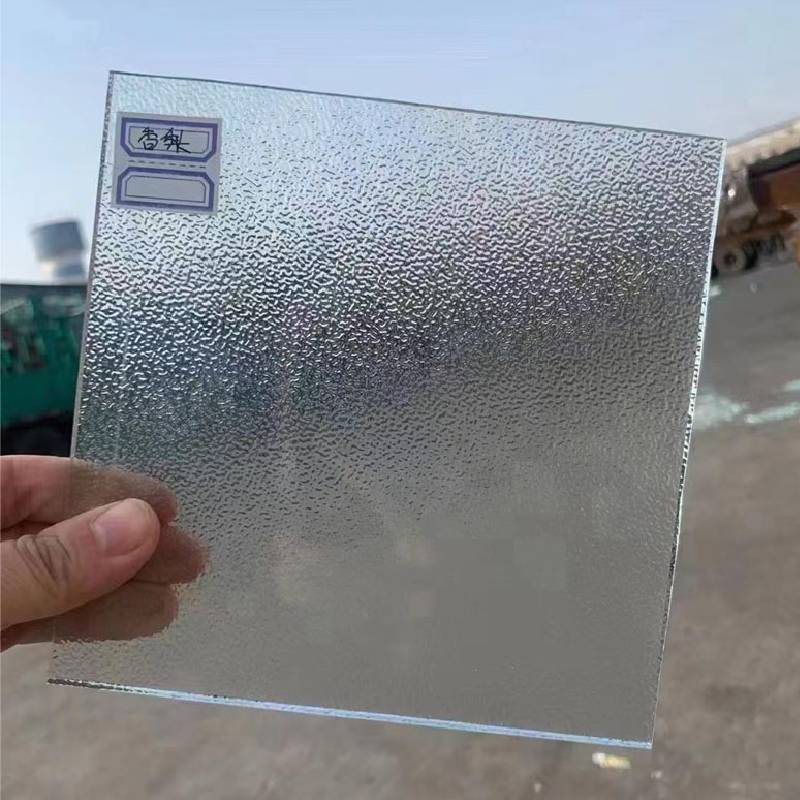

Fig 1. Illustrative application of 3mm 4mm Nashiji obscure pattern glass in a modern interior.

Manufacturing Process: Precision and Quality Assurance

The production of 3mm 4mm Nashiji obscure pattern glass involves a sophisticated sequence of steps, ensuring consistent quality and the distinctive 'pear skin' texture. The primary materials consist of high-quality silica sand, soda ash, limestone, and other raw ingredients, carefully selected for purity and specific melt characteristics. The process is a variation of the rolled glass method, meticulously controlled to meet international standards such as ISO 9001 for quality management.

Process Flow:

- Raw Material Batching: Precise quantities of silica sand, soda ash, limestone, and cullet (recycled glass) are weighed, mixed, and fed into the furnace. This ensures the correct chemical composition for optimal glass properties.

- Melting: The batch materials are melted in a high-temperature furnace (typically around 1500-1600°C) until a homogeneous molten glass mass is achieved. Energy efficiency is a key consideration at this stage, with advanced furnace designs minimizing fuel consumption.

- Forming (Rolling): The molten glass flows from the furnace onto a casting bed, where it passes between two synchronized rollers. One roller is smooth, and the other has the Nashiji pattern engraved on its surface. This imprints the characteristic texture onto one side of the glass sheet, while the other side remains smooth. The thickness (3mm or 4mm) is precisely controlled by the gap between the rollers.

- Annealing: The formed glass sheet enters an annealing lehr, a controlled cooling chamber. Here, the glass is slowly cooled from high temperatures to ambient temperature. This critical step relieves internal stresses that develop during rapid cooling, preventing breakage and enhancing the glass's mechanical strength and durability.

- Cutting and Inspection: Once annealed, the continuous glass ribbon is cut into specific dimensions. Each sheet undergoes rigorous quality inspection for thickness, pattern consistency, visual defects (bubbles, stones, scratches), and overall optical quality. Compliance with standards like ANSI Z97.1 for safety glazing is verified.

- Finishing and Packaging: Edges may be processed (e.g., seamed, polished) as per customer requirements. Finally, the glass sheets are cleaned, packed securely with interleaf material to prevent scratching, and prepared for shipment.

Testing Standards and Service Life:

Our 3mm 4mm Nashiji obscure pattern glass adheres to stringent international quality and safety standards. Key certifications and testing protocols include:

- ISO 9001: Certification for Quality Management Systems, ensuring consistent product quality and customer satisfaction.

- ANSI Z97.1 / EN 12150: If further processed into safety glass (e.g., tempered), it meets these standards for impact resistance and safety glazing.

- ASTM C1036: Standard Specification for Flat Glass, which covers various properties including optical distortion, blemishes, and dimensional tolerances.

With proper installation and maintenance, the service life of 3mm 4mm Nashiji obscure pattern glass is extensive, often exceeding 20-30 years, demonstrating exceptional durability and resistance to environmental degradation. Glass, by its nature, is non-corrosive and does not degrade under normal atmospheric conditions.

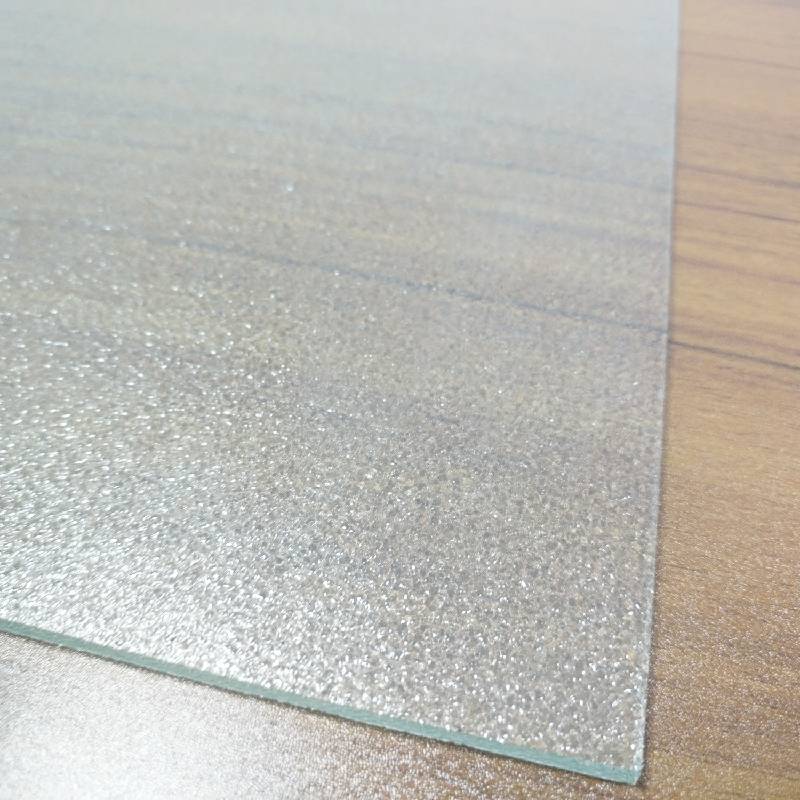

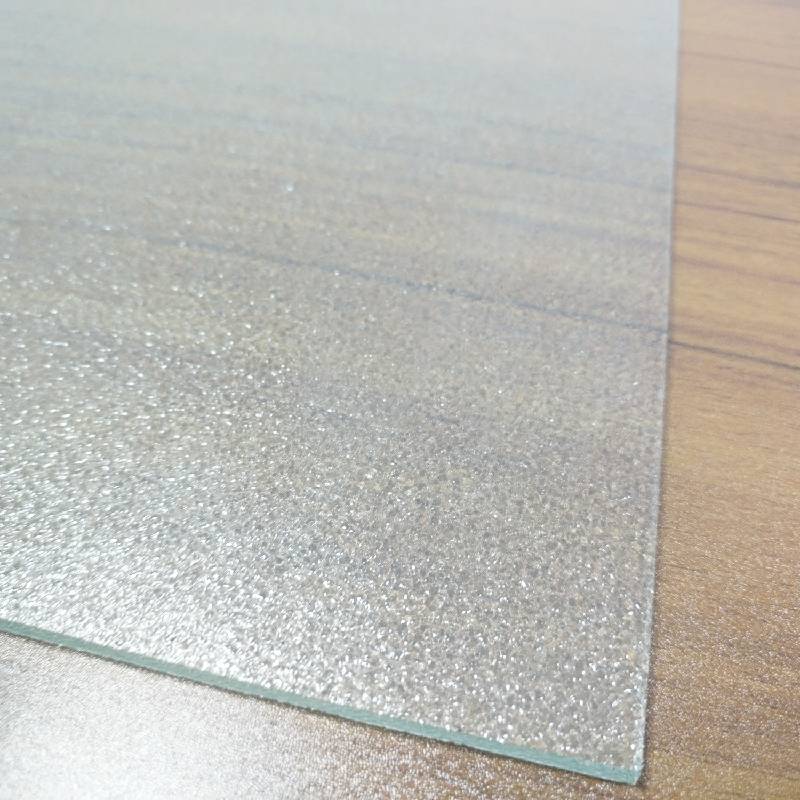

Fig 2. Close-up view revealing the unique Nashiji pattern texture.

Technical Specifications and Parameters

Understanding the precise technical parameters of 3mm 4mm Nashiji obscure pattern glass is crucial for engineers and specifiers in B2B applications. These specifications define the material's performance characteristics, ensuring it meets the rigorous demands of various projects.

Key Physical and Optical Properties:

- Thickness: Available in 3mm and 4mm, offering versatility for different structural and aesthetic requirements.

- Light Transmission: While obscure, Nashiji glass allows for significant light transmission (typically 75-85%), ensuring bright interiors while maintaining privacy.

- Visual Obscurity: The Nashiji pattern effectively distorts views, providing a high degree of privacy without completely blocking light.

- Thermal Expansion Coefficient: Approximately 9.0 x 10^-6 / °C, a standard for soda-lime glass, indicating stable performance across temperature fluctuations.

- Density: Around 2.5 g/cm³, consistent with standard float glass, impacting the weight load calculations for installations.

- Modulus of Elasticity: Approximately 70 GPa, signifying its rigidity and resistance to deformation under stress.

- Chemical Durability: Highly resistant to most chemicals, acids, and alkalis, ensuring longevity in diverse environments.

Product Specification Table:

| Parameter |

Value (3mm Thickness) |

Value (4mm Thickness) |

Relevant Standard |

| Nominal Thickness |

3.0 mm (Tolerance ±0.2mm) |

4.0 mm (Tolerance ±0.2mm) |

ASTM C1036, EN 572-5 |

| Light Transmittance |

~85% |

~82% |

ISO 9050 |

| Density |

2.5 g/cm³ |

2.5 g/cm³ |

EN 572-1 |

| Thermal Expansion Coefficient |

9.0 × 10⁻⁶ / °C |

9.0 × 10⁻⁶ / °C |

ASTM E228 |

| Hardness (Mohs Scale) |

6.0 - 7.0 |

6.0 - 7.0 |

ASTM C730 |

| Maximum Size (Standard) |

2440mm x 3660mm |

2440mm x 3660mm |

Manufacturer Specific |

Fig 3. Quality control inspection of 3mm 4mm Nashiji obscure pattern glass sheets.

Application Scenarios and Target Industries

The unique properties of 3mm 4mm Nashiji obscure pattern glass make it an invaluable material across a diverse range of B2B applications. Its blend of privacy, light diffusion, and aesthetic appeal caters to industries requiring robust yet elegant glazing solutions.

Primary Target Industries:

- Architecture & Construction: Widely used for interior partitions, office doors, bathroom enclosures, shower screens, and balcony railings where privacy is desired without obstructing light.

- Furniture Manufacturing: Incorporated into cabinet doors, tabletops, display cases, and shelving to add decorative flair and obscure contents.

- Lighting & Luminaires: Excellent for light diffusers in lamps, luminaires, and skylights, providing soft, even illumination and reducing glare.

- Hospitality & Retail: Employed in hotel bathrooms, spa facilities, changing rooms, and retail display backdrops for enhanced privacy and aesthetic sophistication.

- Medical & Healthcare Facilities: Used in patient room doors or waiting area partitions to provide patient privacy while allowing ambient light.

- Industrial Facilities (Administrative/Control Areas): In the administrative or control room sections of petrochemical plants, metallurgy facilities, or water supply & drainage operations, Nashiji glass provides privacy for offices and meeting rooms, diffusing harsh industrial lighting and creating a more comfortable working environment for personnel without compromising on the robust, clean aesthetics often required in such sectors. Its ease of cleaning and chemical resistance also make it suitable for these environments.

Typical Application Scenarios & Advantages:

The following scenarios highlight the practical benefits of Nashiji glass:

- Shower Enclosures & Bathroom Doors: The Nashiji pattern provides excellent privacy, preventing clear views while allowing ample light into the space. Its smooth reverse side ensures easy cleaning, and the glass itself is inherently resistant to moisture and mildew. This offers a superior aesthetic and functional solution compared to frosted films or heavily tinted alternatives.

- Office Partitions: In modern open-plan offices, partitions made from Nashiji glass create private meeting rooms or individual workstations. This design choice maintains an open feel, promotes natural light distribution, and reduces the need for artificial lighting, thereby contributing to energy saving and a more pleasant working atmosphere.

- Cabinetry & Furniture Inserts: For furniture manufacturers, integrating Nashiji glass panels into kitchen cabinet doors or sideboards provides a decorative element that elegantly obscures contents, adding sophistication and reducing visual clutter. The glass's inherent durability means a longer service life for the furniture piece.

- Exterior Glazing (select applications): While not typically for entire facades, it can be used in transom windows, side-lites, or certain privacy screens where visual obscurity from the outside is important, such as in changing facilities or sensitive areas within a building. Its robust nature and resistance to environmental factors ensure longevity and minimal maintenance.

Customer feedback consistently praises the balance of privacy and brightness achieved with our Nashiji glass, often noting its superior aesthetic quality compared to alternative obscure glass types. "Our clients appreciate the elegant finish and the effective light diffusion," says a lead architect from a partner firm, emphasizing the material's strong performance in both form and function.

Technical Advantages and Competitive Edge

The strategic deployment of 3mm 4mm Nashiji obscure pattern glass in B2B projects offers distinct technical and practical advantages that set it apart from conventional glazing solutions. These benefits translate directly into enhanced project value, operational efficiency, and long-term performance.

Key Advantages:

- Optimal Light Diffusion: The Nashiji pattern excels at scattering incoming light, minimizing harsh glare and creating a uniformly illuminated space. This reduces eye strain and enhances comfort, particularly in environments with strong direct sunlight.

- Superior Privacy: Its fine-grained texture effectively obscures direct views without significantly reducing natural light intake, making it ideal for sensitive areas requiring both brightness and confidentiality.

- Aesthetic Appeal: The unique 'pear skin' surface provides a sophisticated, non-directional pattern that is less prone to showing fingerprints and smudges than clear or acid-etched glass. It adds an elegant design element that complements modern architectural styles.

- High Durability and Longevity: Manufactured from high-quality soda-lime glass, it boasts excellent resistance to scratches (relative to plastics), chemical degradation, and general wear and tear, ensuring a long service life with minimal maintenance. Its non-porous surface resists corrosion and is easy to clean.

- Safety Enhancements: While inherently durable, this glass can be easily processed further into tempered or laminated safety glass, meeting stringent safety standards (e.g., ANSI Z97.1) for applications where impact resistance or human safety is critical.

- Cost-Effectiveness: Compared to specialty films or integrated privacy systems, patterned glass offers a permanent, maintenance-free solution that often proves more cost-effective over the product lifecycle.

- Thermal Comfort Contribution: By diffusing light, it can help reduce direct solar radiation passing into a building, potentially mitigating localized heat gain and contributing to a more stable internal temperature, indirectly supporting energy-saving initiatives.

Competitive Edge:

Our commitment to precision manufacturing and strict quality control, coupled with our deep understanding of B2B client needs, provides a significant competitive advantage. We offer:

- Consistent Pattern Quality: State-of-the-art rolling technology ensures the Nashiji pattern is uniform and distinct across every sheet, crucial for large-scale projects.

- Broad Customization Options: Beyond standard 3mm and 4mm thicknesses, we offer custom dimensions, edge work, and can facilitate further processing (tempering, lamination) to meet specific project requirements.

- Reliable Supply Chain: Our established production capabilities and logistics network ensure timely and dependable delivery for projects of any scale.

- Technical Support: Expert guidance on specification, installation, and application to optimize performance and ensure project success.

Fig 4. Installation of Nashiji pattern glass in an office partition, enhancing light and privacy.

Vendor Comparison and Customized Solutions

Selecting the right vendor for 3mm 4mm Nashiji obscure pattern glass is a critical decision for B2B procurement. While many suppliers offer patterned glass, distinctions in quality, service, and customization capabilities are significant. Our commitment to excellence ensures superior product delivery and tailored solutions.

Vendor Comparison Table:

| Feature |

Our Offering |

Typical Competitor |

| Glass Quality (Raw Material Purity) |

Premium, low-iron silica for enhanced clarity and consistency. |

Standard industrial-grade raw materials; may show slight tint. |

| Pattern Consistency & Definition |

High-precision rolling, uniform pattern depth and clarity across sheets. |

Variations in pattern definition, potential for inconsistent obscurity. |

| Thickness Range & Tolerance |

Strict control (±0.2mm for 3/4mm), wider custom thickness options. |

Broader tolerances (±0.3-0.5mm), limited standard thicknesses. |

| Certifications & Standards |

ISO 9001 certified, adherence to ASTM, EN, ANSI as applicable. |

May offer basic certifications, less stringent adherence. |

| Customization Capabilities |

Extensive: custom sizes, edge work, drilling, tempering, lamination. |

Limited to standard sizes and basic edge finishing. |

| Lead Time & Logistics |

Optimized production & logistics for reliable, on-time delivery. |

Can be subject to longer lead times, less flexible shipping. |

| Technical Support |

Dedicated technical team for specification and application guidance. |

Basic customer service, limited technical expertise. |

Customized Solutions:

Recognizing that every B2B project has unique demands, we offer comprehensive customization options for our 3mm 4mm Nashiji obscure pattern glass:

- Size and Shape: Beyond standard sheet dimensions, we can cut glass to precise custom sizes and complex shapes to fit specific architectural or design requirements.

- Edge Work: Various edge finishes are available, including seamed, ground, polished (flat or pencil), and bevelled, to suit aesthetic and safety needs.

- Hole Drilling and Notches: Precise drilling for hardware (e.g., hinges, handles, standoffs) and custom notches are expertly executed according to technical drawings.

- Further Processing: Our Nashiji glass can be heat-treated (tempered) for enhanced strength and safety, or laminated with PVB interlayers for increased security and acoustic performance. This ensures compliance with various building codes and performance specifications.

- Integrated Solutions: We collaborate with clients to develop integrated glass solutions, combining Nashiji glass with other glass types (e.g., low-E coatings, tinted glass) to achieve multi-functional performance.

Our experienced technical team works closely with clients from concept to completion, providing expert advice and engineering support to ensure that customized solutions precisely meet project specifications and exceed expectations.

Application Case Studies

Real-world implementations demonstrate the tangible benefits and versatility of 3mm 4mm Nashiji obscure pattern glass in diverse B2B environments. These case studies highlight our product's performance and our company's commitment to quality and client satisfaction.

Case Study 1: Corporate Office Partitioning

- Client: Global Financial Services Firm, London Branch

- Challenge: Create private meeting rooms and executive offices within an open-plan layout, while maximizing natural light and maintaining a modern, sophisticated aesthetic. Traditional solid walls would block light and feel oppressive.

- Solution: Over 1,500 square meters of 4mm tempered Nashiji obscure pattern glass were supplied for floor-to-ceiling partitions. Custom cuts and door panels were integrated with sleek aluminum framing systems.

- Results: The Nashiji glass successfully diffused light from perimeter windows deep into the office space, significantly reducing the need for artificial lighting during the day. It provided optimal visual privacy for sensitive discussions without making the offices feel isolated. The 'pear skin' texture contributed to the office's upscale design, exceeding client expectations for both functionality and aesthetics. The project was completed on schedule, a testament to our efficient lead times and project management.

Case Study 2: Luxury Hotel Bathroom Enclosures

- Client: Five-Star Boutique Hotel, Paris

- Challenge: Design elegant and private shower and toilet enclosures for guest suites, allowing natural light from the main room to filter into the bathroom while maintaining a high degree of visual obscurity.

- Solution: We provided 3mm tempered Nashiji obscure pattern glass, custom-cut for shower doors and fixed panels. The glass was specified with polished edges and pre-drilled holes for bespoke hardware. Our product met EN 12150 safety standards for tempered glass.

- Results: The Nashiji glass delivered the perfect balance of privacy and light, creating bright and inviting bathrooms that felt luxurious and spacious. Hotel management praised the ease of cleaning and the glass's ability to resist water spots, which is crucial for maintaining a pristine guest experience. The project highlighted our ability to deliver high-quality, customized solutions for discerning clients.

Fig 5. Architectural application of 3mm 4mm Nashiji obscure pattern glass in a commercial setting.

Commitment to Trust: FAQ, Lead Time, Warranty & Support

Building long-term partnerships in the B2B sector is founded on trust, transparency, and reliable support. Our commitment extends beyond product delivery to encompass comprehensive pre-sales and after-sales services for 3mm 4mm Nashiji obscure pattern glass.

Frequently Asked Questions (FAQ):

Q: Can Nashiji glass be tempered for safety applications?

A: Yes, our 3mm and 4mm Nashiji obscure pattern glass can be fully tempered to enhance its strength and meet safety glazing standards (e.g., ANSI Z97.1, EN 12150). Tempering makes the glass up to five times stronger than annealed glass and, if broken, it shatters into small, blunt fragments, reducing injury risk.

Q: How does the Nashiji pattern affect light transmission?

A: The Nashiji pattern diffuses light very effectively, scattering it across the space rather than allowing direct, harsh light. While providing high obscurity, it maintains a light transmission rate of approximately 75-85%, ensuring spaces remain bright and welcoming.

Q: Is Nashiji glass suitable for outdoor use?

A: Yes, being made of soda-lime glass, it is highly durable and resistant to weathering, UV radiation, and most environmental conditions, making it suitable for certain exterior applications like privacy screens, balcony railings (when tempered/laminated), or decorative panels in sheltered areas.

Q: What are the cleaning requirements for Nashiji glass?

A: Nashiji glass is relatively easy to clean. The smooth side can be cleaned with standard glass cleaner. For the patterned side, a soft cloth or brush with a mild detergent solution is recommended to ensure dirt does not accumulate in the texture. Regular cleaning maintains its optical clarity and aesthetic.

Lead Time and Fulfillment:

We understand the importance of timely project delivery. Our standard lead time for stocked 3mm and 4mm Nashiji obscure pattern glass is typically 7-14 business days, depending on order volume and cutting requirements. For customized solutions involving tempering, lamination, or complex fabrication, lead times will be provided with a detailed quote, usually ranging from 3-5 weeks. We maintain robust inventory levels and efficient production lines to minimize delays and ensure consistent fulfillment.

Warranty Commitments:

We stand by the quality of our products. All 3mm 4mm Nashiji obscure pattern glass supplied comes with a comprehensive 10-year warranty against manufacturing defects that impair its function or aesthetic appeal. This warranty covers issues such as delamination (for laminated glass), pattern degradation, and significant optical defects under normal use and maintenance conditions. Full warranty details are available upon request and are included with every major order.

Customer Support:

Our dedicated customer support team is available to assist B2B clients at every stage of their project. From initial inquiry and technical specification guidance to order tracking and after-sales support, we are committed to providing prompt, knowledgeable, and reliable service. Contact us via phone, email, or our online portal for technical consultations, quotes, or any inquiries regarding our 3mm 4mm Nashiji obscure pattern glass products.

References

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems - Requirements.

- ASTM International. (2014). ASTM C1036-14 - Standard Specification for Flat Glass.

- European Committee for Standardization. (2018). EN 572-1:2018 - Glass in building - Basic soda-lime silicate glass products - Part 1: Definitions and general physical and mechanical properties.

- American National Standards Institute. (2017). ANSI Z97.1-2017 - Safety Glazing Materials Used in Buildings - Safety Performance Specifications and Methods of Test.

- Glass for Europe. (2020). The role of glass in sustainable buildings. (Industry report)