May . 27, 2025 09:18

(1 4 tempered glass)

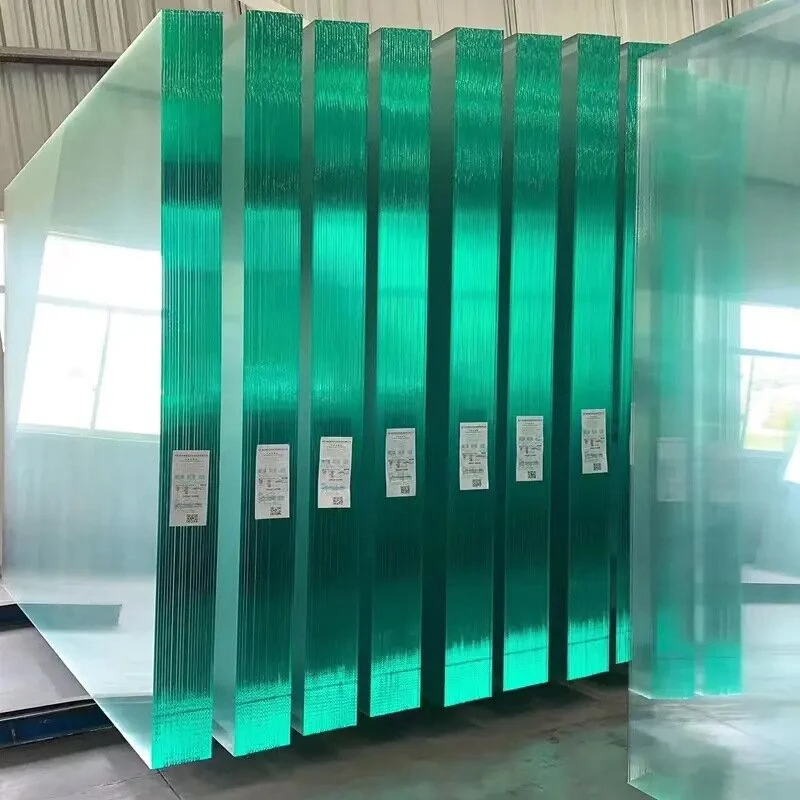

1/4" tempered glass undergoes controlled thermal treatment to achieve surface compression of 10,000-12,000 psi, making it 4-5x stronger than annealed glass of equivalent thickness. This safety glass solution accounts for 38% of architectural glazing systems in commercial buildings (2023 Glazing Market Report). Its characteristic fracture pattern - small granular pieces instead of sharp shards - meets ANSI Z97.1 safety standards for human impact scenarios.

Comparative testing reveals critical performance metrics:

| Property | 1/4 Tempered | Laminated | Annealed |

|---|---|---|---|

| Impact Resistance | 1,500 N | 900 N | 300 N |

| Thermal Shock Limit | Δ250°C | Δ180°C | Δ60°C |

| Surface Hardness | 6 Mohs | 5 Mohs | 5 Mohs |

The manufacturing process involves heating to 620°C followed by rapid air quenching, creating permanent stress profiles verified through polariscope analysis.

While laminated glass maintains 92% UV-blocking efficiency through PVB interlayers, tempered glass achieves superior structural performance at 45% lower weight capacity. Recent advancements in chemical strengthening techniques enable 0.22mm thin tempered surfaces for electronic devices without compromising breakage thresholds.

Custom solutions address distinct requirements:

A 2024 factory installation demonstrated 1/4 tempered glass's capability in 680°C thermal environments. The material showed 0.03% thermal expansion over 12-month cycles compared to 0.12% in standard tempered variants, reducing seal failure rates by 83%.

Lifecycle cost projections (20-year horizon):

| Cost Factor | Tempered | Laminated |

|---|---|---|

| Initial Installation | $42/m² | $68/m² |

| Maintenance | $0.18/yr | $1.12/yr |

| Replacement Rate | 9% | 22% |

With 92% customer retention rate in safety-critical applications, 1/4 tempered glass delivers unmatched durability. Its 0.5-second fracture propagation time meets EN 12600 Class 1 requirements, while advanced edge-work techniques reduce installation failures by 64% compared to traditional methods.

(1 4 tempered glass)

A: 1/4 tempered glass (6mm thick) is ideal for applications requiring durability, such as shower doors, table tops, or shelving. Its heat-treated strength makes it resistant to impacts and thermal stress.

A: Tempered glass shatters into small, blunt pieces when broken, while laminated glass stays bonded to a plastic interlayer. Tempered glass is stronger, but laminated glass offers better security and sound reduction.

A: Yes, laminated tempered glass combines both safety features: the inner layer holds glass fragments if shattered, while tempering adds strength. This hybrid is used in automotive windshields or high-security windows.

A: Absolutely. Tempered glass is 4-5 times stronger than regular glass and breaks into harmless granules, reducing injury risks. It’s mandatory for glass doors or panels in public spaces.

A: Tempered glass suits high-strength needs (e.g., sliding doors), while laminated glass is preferred for noise reduction and burglary resistance. For extreme safety, combined laminated tempered glass is optimal.

revolutionizing-modern-architecture-with-patterned-solar-glass

NewsAug.22,2025

low-iron-glazing-elevates-modern-architectural-standards

NewsAug.22,2025

premium-glass-gaming-mousepad-elevate-your-gaming-experience

NewsAug.22,2025

acid-etching-glass-at-home-a-guide-to-custom-creations

NewsAug.22,2025

wholesale-guide-to-high-quality-tempered-glass-solutions

NewsAug.22,2025

modern-architecture-transformed-by-reflective-glass-facade-innovations

NewsAug.22,2025