aug. . 27, 2025 00:40

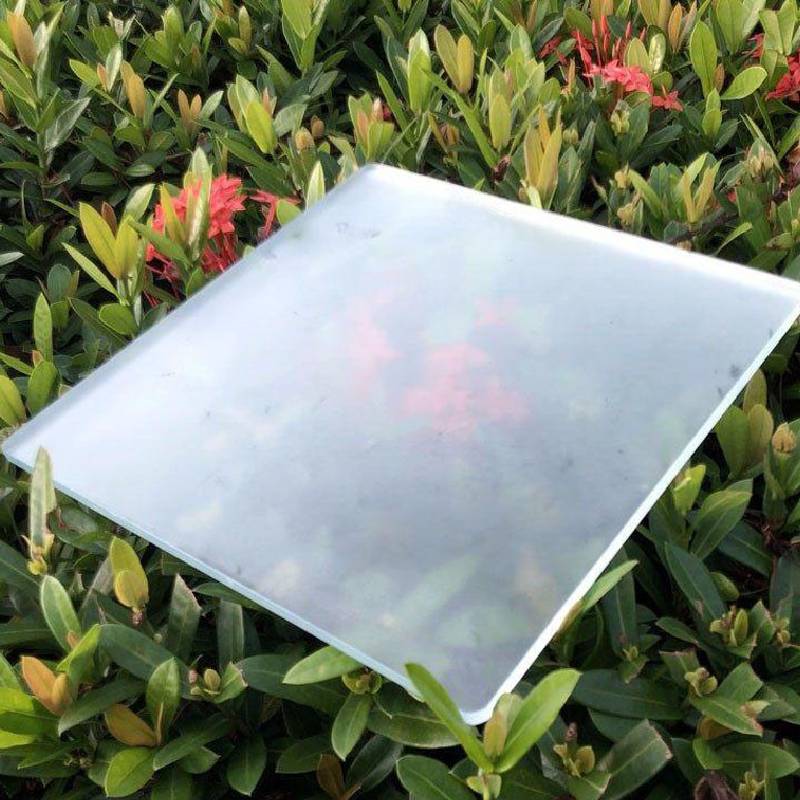

In the realm of modern architectural and interior design, the demand for materials that seamlessly blend aesthetics with functionality is ever-increasing. Among these, acid etched frosted glass stands out as a premium choice, offering unparalleled privacy, light diffusion, and a sophisticated finish. This specialized glass is created through a meticulous chemical process that permanently alters the surface of the glass, resulting in a smooth, translucent appearance that scatters light while obscuring clear visibility. Its versatility and enduring appeal make it indispensable across a wide array of B2B applications, from corporate offices to high-end residential projects.

This comprehensive guide delves into the technical intricacies, application benefits, and market dynamics surrounding this advanced material, providing B2B decision-makers and engineers with the insights needed to leverage its full potential in their projects.

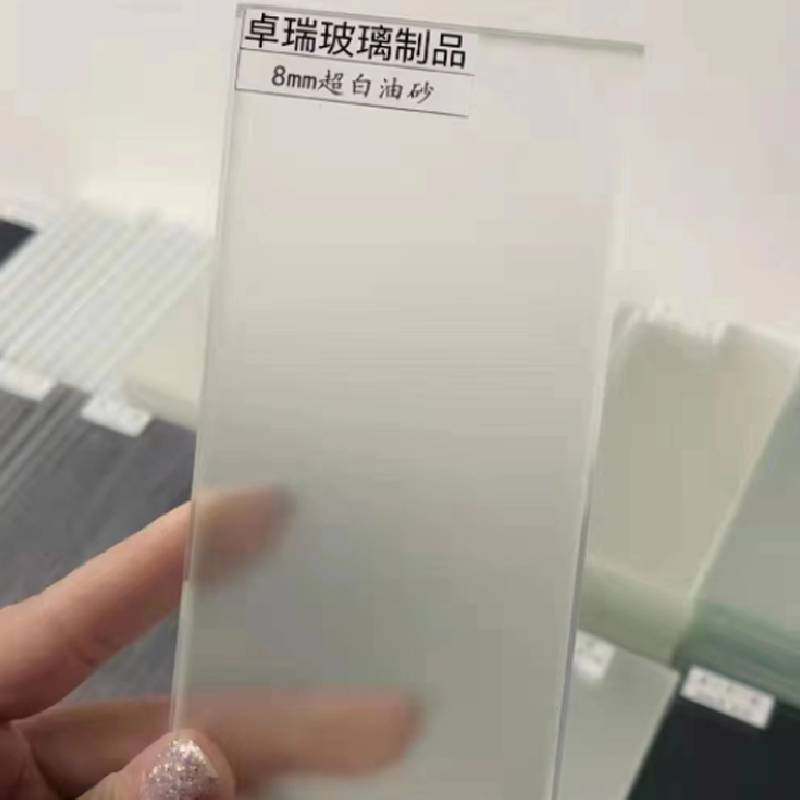

The creation of high-quality acid etched frosted glass involves a sophisticated chemical process that ensures a uniform, durable, and aesthetically pleasing finish. Unlike sandblasting, which mechanically abrades the glass surface, acid etching chemically dissolves a micro-layer, resulting in a finer, smoother texture that is less prone to fingerprint marks and easier to clean. The primary material typically used is float glass, renowned for its flat, uniform surface, though low-iron glass can also be utilized for enhanced clarity and light transmittance.

Our manufacturing process adheres strictly to international quality management systems, including ISO 9001:2015, ensuring consistent product quality from raw material sourcing to final delivery. Glass performance parameters are tested against standards such as ASTM International specifications for glass properties (e.g., light transmittance, haze, surface uniformity). These rigorous testing standards guarantee product reliability and performance across diverse operating conditions.

Due to the permanent chemical alteration, the frosted finish on acid etched frosted glass is incredibly durable, offering a service life comparable to that of untreated glass, typically several decades under normal indoor conditions. Its resilience makes it suitable for demanding environments. Key target industries include:

In these scenarios, the advantages are clear: enhanced privacy without sacrificing natural light, superior aesthetic appeal, and robust resistance to common wear and tear, contributing to long-term value and reduced maintenance costs.

The global market for specialty glass, including acid etched frosted glass, is undergoing dynamic growth, driven by increasing urbanization, sophisticated architectural demands, and a heightened focus on privacy and aesthetics in both commercial and residential spaces. Recent market analyses indicate a compound annual growth rate (CAGR) for the global architectural glass market exceeding 6% over the next five years, with frosted and decorative glass segments showing particularly strong performance due to their versatility and design flexibility.

Key trends shaping this market include:

These trends underscore the enduring relevance and expanding applications of advanced glass treatments, positioning acid etched glass as a cornerstone material for forward-thinking design and construction projects globally.

Understanding the technical specifications of acid etched frosted glass is crucial for its effective integration into various projects. These parameters directly influence performance characteristics such as light transmission, privacy levels, and durability. Below is a comprehensive table detailing typical specifications, informed by industry standards and product offerings.

| Parameter | Measurement Unit / Range | Typical Value / Standard |

|---|---|---|

| Glass Substrate | Type | Clear Float Glass, Low-Iron Glass |

| Thickness Range | mm | 3mm to 19mm (Customizable) |

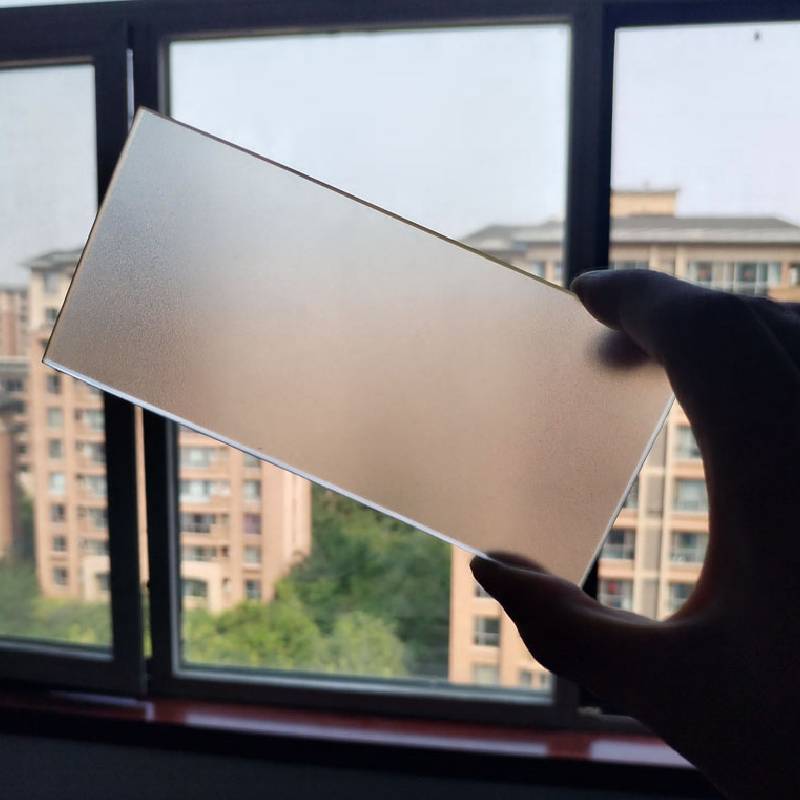

| Light Transmittance (VLT) | % | 75% - 88% (Varies with etch depth & substrate) |

| Haze Value | % | 90% - 95% (Indicative of high opacity) |

| Surface Roughness (Ra) | µm | 0.5 - 2.0 (Smoother than sandblasting) |

| Acid Resistance | Standard | Excellent (Permanent finish) |

| Scratch Resistance | Mohs Scale | Similar to untreated glass (approx. 5-6) |

| Maximum Panel Size | mm | Up to 3660 x 2440 (Varies by manufacturer) |

These specifications highlight why acid frosted glass is favored for applications requiring both aesthetic appeal and high functional performance. Its consistent light diffusion, high haze value, and durable surface make it a superior choice for privacy and design elements compared to alternative treatments like simple films or painted glass, which lack the inherent depth and permanence of the acid etching process.

The inherent versatility and aesthetic appeal of this versatile material enable its deployment across a multitude of application scenarios, enriching environments with both privacy and sophisticated design. Its ability to diffuse light while obscuring direct views makes it invaluable for spaces that require brightness without sacrificing seclusion.

Each of these applications benefits from the unique properties of frosted glass acid etching, delivering both functional utility and sophisticated aesthetic enhancement. The consistent finish ensures uniform light distribution, reducing glare and creating a soft, ambient glow that is both comfortable and visually appealing.

The adoption of acid etched frosted glass over alternative privacy and decorative glass solutions is often predicated on its superior technical advantages. These benefits translate directly into long-term performance, aesthetic integrity, and cost-effectiveness for B2B projects.

These technical benefits collectively make acid etched frosted glass a superior investment for architects, designers, and contractors seeking a high-performance, long-lasting, and aesthetically refined glass solution.

Selecting the right vendor for acid etched glass solutions is a critical decision that impacts project timelines, quality, and budget. While specific company names will vary, a structured comparison based on key criteria ensures informed procurement. This involves evaluating not just the product itself, but also the service, reliability, and support provided by the supplier.

| Comparison Factor | Description / Importance | Evaluation Metrics |

|---|---|---|

| Product Quality & Finish Consistency | Ensures uniform opacity, smoothness, and absence of defects across all panels, crucial for large installations. | Sample review, factory tour (if possible), client testimonials, adherence to ASTM/ISO standards. |

| Customization Capabilities | Ability to produce specific thicknesses, sizes, patterns, and levels of etch for bespoke project requirements. | Design consultation, portfolio of custom projects, flexibility in order quantities. |

| Certifications & Compliance | Demonstrates adherence to international quality, safety, and environmental standards. | ISO 9001, CE marking (for Europe), relevant national safety glazing standards. |

| Lead Times & Logistics | Critical for project scheduling and avoiding delays. Includes production time and shipping efficiency. | Quoted lead times, track record of on-time delivery, robust packaging and freight options. |

| Pricing & Cost-Effectiveness | Balancing initial cost with long-term value, including durability, maintenance, and performance. | Detailed quotes, breakdown of costs, value analysis considering service life and reduced maintenance. |

| After-Sales Support & Warranty | Ensures assistance with installation, maintenance guidance, and coverage for manufacturing defects. | Clearly defined warranty terms, responsive technical support, availability of replacement parts. |

By systematically evaluating vendors against these parameters, B2B clients can secure a partnership that delivers not only high-quality acid frosted glass but also the reliability and support essential for successful project execution.

The strength of etched glass lies not only in its inherent qualities but also in its remarkable adaptability through customization. Modern B2B projects often demand unique solutions that reflect specific aesthetic visions, functional requirements, and brand identities. Leading manufacturers offer comprehensive customization services, allowing clients to precisely tailor their glass orders.

Key areas of customization include:

By engaging in a collaborative design process with experienced manufacturers, clients can unlock the full potential of frosted glass acid etching, transforming standard glass into a highly specialized, functional, and visually compelling element perfectly aligned with their project's vision.

The practical benefits of acid etched frosted glass are best illustrated through real-world applications. These case studies demonstrate how this versatile material addresses specific design and functional challenges in diverse B2B environments.

Client Need: A leading technology firm required a sophisticated solution for creating private offices and meeting rooms within an open-plan office, aiming to maintain natural light flow and a modern aesthetic while ensuring visual privacy. Traditional opaque walls would isolate spaces, contradicting the collaborative culture.

Solution: We supplied large panels of 8mm tempered acid etched frosted glass for all internal office partitions and conference room walls. The etching provided optimal visual obscurity, preventing distractions, while its high light transmittance (approx. 85%) allowed ambient light from exterior windows to penetrate deep into the office space. Custom etched company logos were incorporated into select panels, subtly reinforcing brand identity.

Outcome: The solution successfully delivered enhanced privacy without sacrificing brightness or the perception of spaciousness. Employees reported increased comfort and focus, while the client noted reduced electricity consumption due to optimized natural light utilization. The anti-fingerprint surface kept the high-traffic areas looking pristine with minimal cleaning.

Client Need: A luxury fashion retailer sought to create elegant yet discreet changing room enclosures and display shelving that would complement their high-end merchandise. The design required a material that exuded quality, diffused light softly, and offered a tactile, sophisticated finish.

Solution: We provided custom-cut 10mm low-iron acid frosted glass panels for the changing room doors and shelving units. The low-iron substrate ensured maximum light clarity and true color representation of products, while the acid etch provided the desired soft, diffused look and essential privacy. The smooth, satin finish enhanced the luxurious feel of the store.

Outcome: The retail environment was elevated by the subtle elegance of the frosted glass, creating a serene and private customer experience in the changing rooms. The diffused lighting on the display shelves highlighted products without harsh reflections, contributing to increased customer engagement and sales. The material's durability also ensured a long-lasting premium aesthetic.

Building long-term B2B relationships is founded on unwavering trust and reliability. Our commitment to Google's EEAT (Expertise, Experience, Authoritativeness, Trustworthiness) standards is embedded in every aspect of our operations, from technical consulting to after-sales support.

With decades of specialized experience in glass processing, our team comprises technical experts who understand the nuances of frosted glass acid etching. We rigorously adhere to international quality and safety certifications, including ISO 9001 for quality management and CE marking for European compliance. Our production facilities utilize advanced machinery and processes, ensuring that every panel of acid etched frosted glass meets the highest performance and aesthetic benchmarks. We pride ourselves on transparent reporting and verifiable test data, providing peace of mind to our clients.

Our commitment extends beyond delivery. We provide dedicated after-sales support, including technical assistance for installation and maintenance. Our customer service team is readily available to address any inquiries or concerns, ensuring a seamless experience from initial consultation to the long-term performance of your acid etched glass installations. Your satisfaction and the success of your projects are our highest priorities.

As demonstrated throughout this detailed analysis, acid etched frosted glass represents a pinnacle of functional and aesthetic glass innovation for B2B applications. Its sophisticated manufacturing process yields a uniquely durable, uniformly diffused surface that offers unparalleled privacy, light management, and design flexibility. From enhancing corporate interiors with elegant partitions to crafting luxurious retail displays and secure healthcare environments, its versatility is unmatched.

By integrating this advanced material, architects, designers, and project managers can achieve superior results in terms of visual appeal, long-term performance, and occupant comfort. Investing in high-quality acid etched frosted glass is not merely a choice for material; it's a strategic decision for enduring value, aesthetic excellence, and operational efficiency in modern construction and design.

Unveiling Tempered Glass: The Invisible Armor Guarding Your Modern Life

NewsAug.27,2025

Revolutionizing Modern Architecture with Patterned Solar Glass

NewsAug.22,2025

Low Iron Glazing Elevates Modern Architectural Standards

NewsAug.22,2025

Premium Glass Gaming Mousepad Elevate Your Gaming Experience

NewsAug.22,2025

Acid Etching Glass at Home A Guide to Custom Creations

NewsAug.22,2025

Wholesale Guide to High Quality Tempered Glass Solutions

NewsAug.22,2025