ఏప్రి . 29, 2025 11:49

(toughened glass definition)

Toughened glass, also known as tempered glass, undergoes a thermal treatment process to enhance its structural integrity. By heating float glass to approximately 620°C followed by rapid cooling, surface compression increases to 10,000–15,000 psi, making it 4–5 times stronger than standard glass. This process aligns with ASTM C1048 standards, ensuring consistent quality for architectural and industrial uses.

Float glass, produced via molten tin bath methods, serves as the base material for 92% of tempered glass products. Unlike toughened variants, untreated float glass fractures into sharp shards, limiting its use in safety-critical environments. Key distinctions include:

Modern manufacturing techniques enable toughened glass to achieve:

| Manufacturer | Thickness Range | Max. Dimensions | Lead Time | Price/Sqft (USD) |

|---|---|---|---|---|

| Guardian Glass | 3–19mm | 3000x6000mm | 14 days | $18–$45 |

| Saint-Gobain | 4–25mm | 3300x8000mm | 21 days | $22–$60 |

| Vitro Glass | 2–12mm | 2440x6000mm | 10 days | $15–$38 |

Specialized treatments extend toughened glass functionality:

A 2023 commercial high-rise project utilized 12mm tempered glass facades achieving:

The global tempered glass market ($64.2B in 2023) drives innovation in:

(toughened glass definition)

A: Toughened glass, also known as tempered glass, is a type of safety glass processed by controlled thermal or chemical treatments. It is 4-5 times stronger than regular glass and shatters into small, granular pieces to reduce injury risk.

A: Float glass is made by melting silica and floating it on molten tin, producing smooth, clear sheets. Toughened glass undergoes additional heating and rapid cooling to enhance strength, unlike untreated float glass.

A: Yes, "tempered glass" and "toughened glass" refer to the same material. The terms are interchangeable, describing glass strengthened through thermal tempering for improved durability and safety.

A: Float glass is a base glass type created by floating molten glass on molten tin, resulting in uniform thickness and distortion-free surfaces. It is the foundation for products like windows and mirrors before further processing.

A: Toughened glass is used in high-safety applications like car windows, shower doors, and building facades. Its resistance to breakage and safe fragmentation make it ideal for public spaces and structural designs.

The Role of Mirror Glass in Luxury Interior Design

NewsJun.23,2025

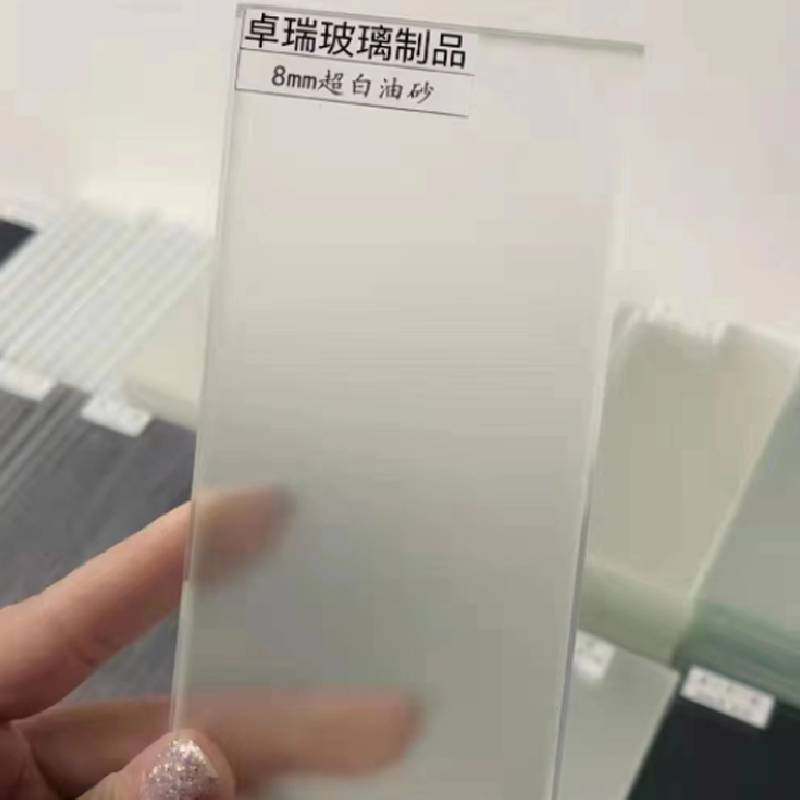

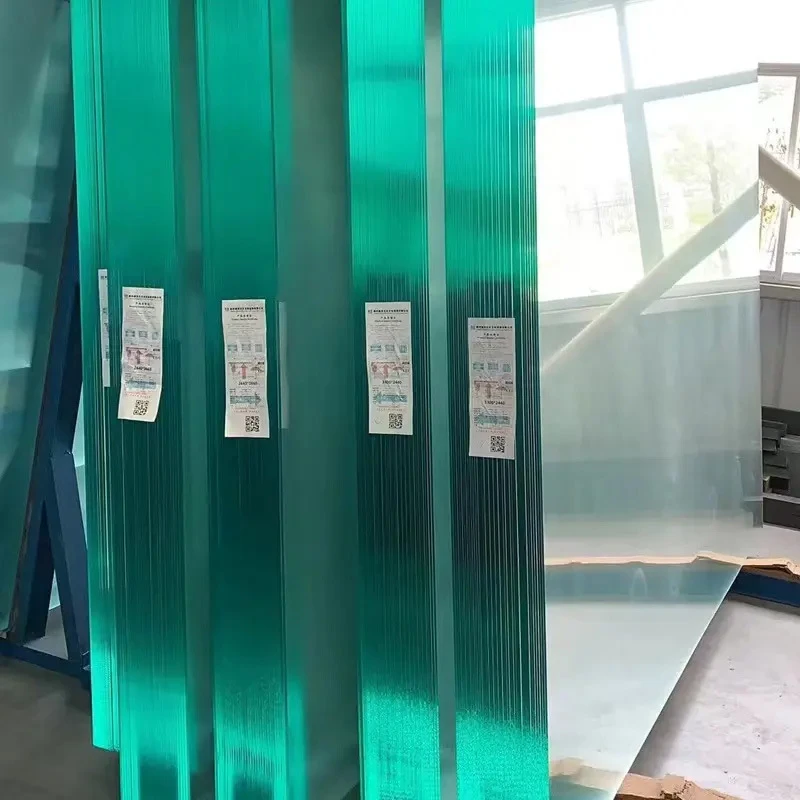

The Best Textured Glass for Bathroom Windows

NewsJun.23,2025

Residential Glazing Energy Efficiency Requirements

NewsJun.23,2025

Float Glass Uses

NewsJun.23,2025

Clear Float Glass For Solar Panel Covers

NewsJun.23,2025

Benefits Of Using A Glass Mouse Pad Over Traditional Ones

NewsJun.23,2025