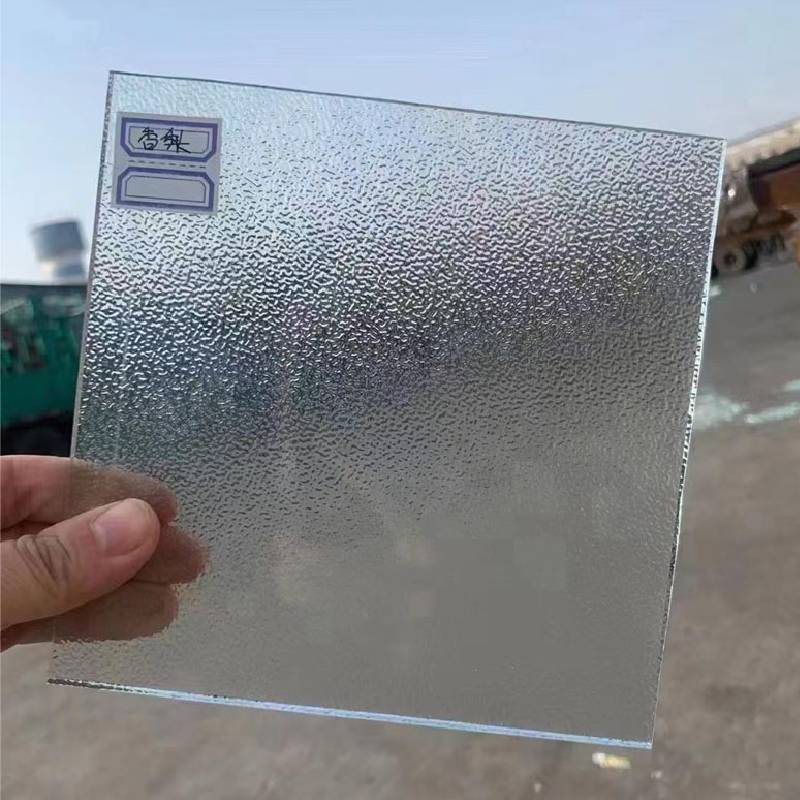

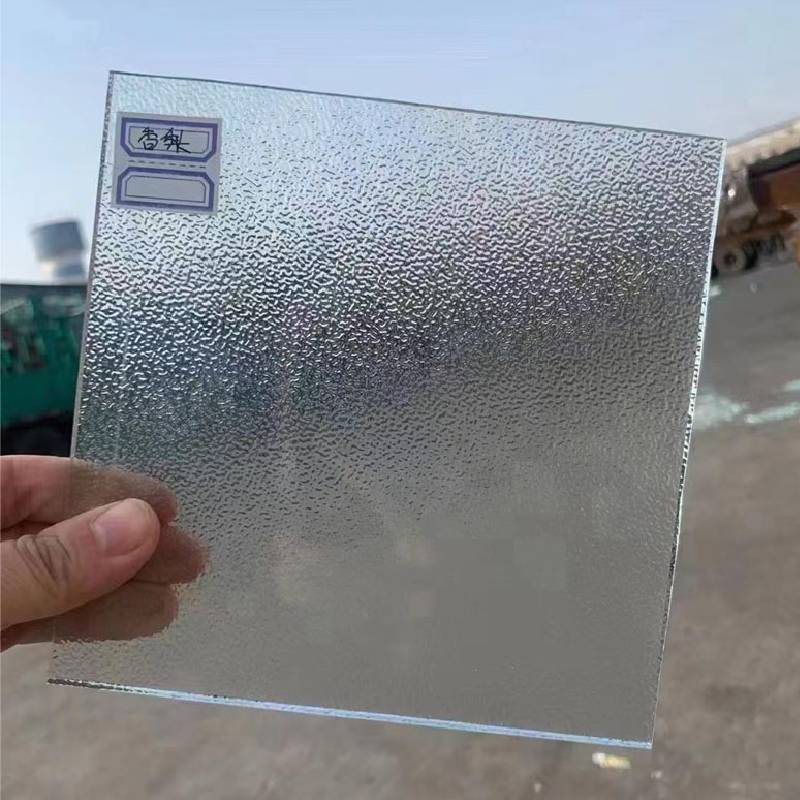

Introduction to 3mm 4mm Nashiji Obscure Pattern Glass

In modern architectural and interior design, the demand for materials that offer both aesthetic appeal and functional privacy has never been higher. Among the various specialized glass products, 3mm 4mm Nashiji obscure pattern glass stands out as a versatile and popular choice. Nashiji glass, characterized by its distinctive, fine-grained, non-directional pattern resembling pear skin (hence "Nashiji," a Japanese term), effectively diffuses light while maintaining a high degree of visual obscurity. Available in commonly specified thicknesses of 3mm and 4mm, it provides an optimal balance of structural integrity and aesthetic delicacy, making it ideal for a multitude of applications where light transmission is desired without full transparency.

This article delves into the technical aspects, manufacturing processes, application scenarios, and key advantages of this specialized glass, aiming to provide B2B decision-makers and technical professionals with comprehensive insights into its value proposition.

Industry Trends and Market Dynamics

The global architectural glass market is experiencing robust growth, driven by increasing construction activities, urbanization, and a heightened focus on energy efficiency and aesthetic design. Within this broader market, the segment for patterned and obscure glass is particularly dynamic. Key trends include:

- Demand for Privacy Solutions: As living and working spaces become more compact, there's a growing need for elegant solutions that offer privacy without sacrificing natural light. Obscure pattern glass, like Nashiji, is perfectly positioned to meet this demand in various settings, from office partitions to residential bathrooms.

- Aesthetic Versatility: Designers are increasingly seeking materials that contribute to unique interior aesthetics. The subtle yet distinct pattern of Nashiji glass offers a sophisticated texture that complements a wide range of design styles, from minimalist to contemporary.

- Sustainability and Energy Efficiency: While not a primary energy-saving material in itself, patterned glass can be integrated into insulated glass units (IGUs) to enhance thermal performance. Its light diffusion properties can also reduce glare, potentially lowering the need for artificial lighting and contributing to energy savings.

- Safety and Security: When tempered or laminated, patterned glass can enhance safety by reducing the risk of injury from breakage, making it suitable for high-traffic areas or environments requiring specific safety standards.

These trends collectively underscore the increasing relevance and market potential of specialized glass products such as 3mm 4mm Nashiji obscure pattern glass in both commercial and residential sectors.

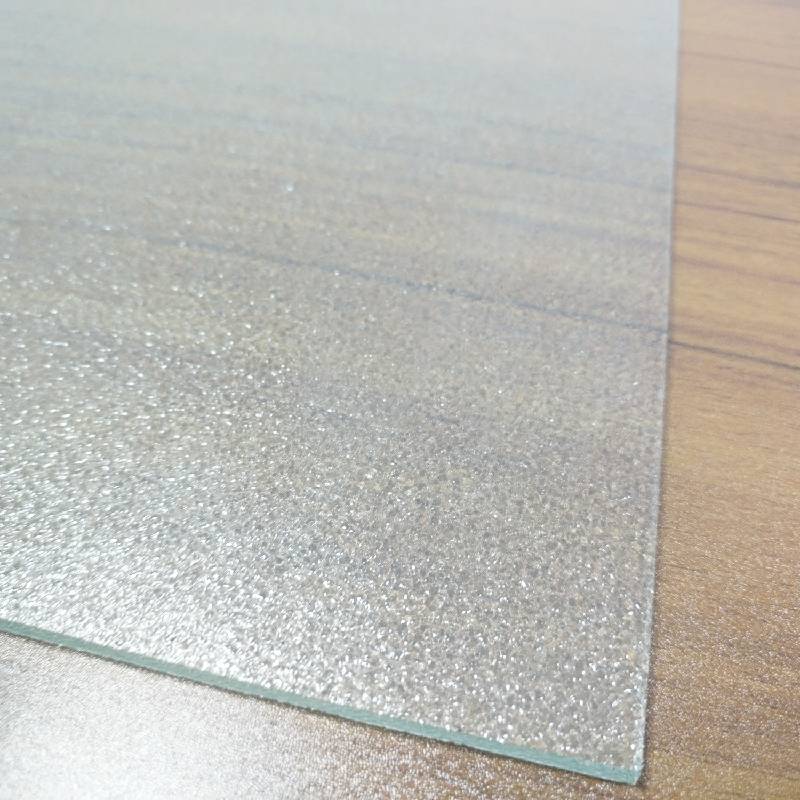

Technical Specifications and Performance Parameters

Understanding the technical specifications of 3mm 4mm Nashiji obscure pattern glass is crucial for its appropriate selection and application. This glass is manufactured to achieve specific optical and physical properties that ensure its suitability for various architectural and functional requirements.

Key Properties:

- Thickness: Primarily available in 3mm and 4mm. These thicknesses offer a balance of cost-effectiveness, weight, and structural integrity for most interior and semi-exposed applications.

- Light Transmission: Typically ranges from 70% to 85%, depending on thickness and exact pattern depth. This high light transmission ensures interior spaces remain bright while maintaining privacy.

- Haze Level (Obscurity): Nashiji patterns are known for their effective light diffusion and high obscurity levels, typically achieving 90-95% visual obscurity. This makes it challenging to discern distinct shapes or objects through the glass, even at close range.

- Pattern Type: "Nashiji" refers to a fine, granular, non-directional pattern that disperses light evenly across its surface, eliminating sharp shadows and creating a soft, ambient glow.

- Substrate: Typically manufactured from clear float glass, ensuring minimal color distortion and optimal clarity before patterning. Ultra-clear (low-iron) options are also available for enhanced light transmission and color neutrality.

Product Specification Table:

| Parameter |

3mm Nashiji Glass |

4mm Nashiji Glass |

| Nominal Thickness (mm) |

3.0 ± 0.2 |

4.0 ± 0.2 |

| Light Transmittance (%) |

~85 |

~80 |

| Visual Obscurity Level |

High (90-95%) |

High (90-95%) |

| Max Panel Size (typically) |

2440 x 3660 mm |

2440 x 3660 mm |

| Density (kg/m³) |

~2500 |

~2500 |

| Thermal Expansion Coefficient (per °C) |

9 x 10⁻⁶ |

9 x 10⁻⁶ |

| Hardness (Mohs Scale) |

5.5 - 6.0 |

5.5 - 6.0 |

These parameters adhere to international standards such as ISO 9001 for quality management and relevant ASTM or EN standards for glass products, ensuring consistency and performance reliability.

Detailed Manufacturing Process Flow

The production of 3mm 4mm Nashiji obscure pattern glass involves a series of sophisticated steps, ensuring the unique pattern and optical properties are consistently achieved. This process is a specialized form of rolled glass manufacturing, distinct from traditional float glass production.

Process Steps:

- Raw Material Preparation: High-quality silica sand, soda ash, limestone, and other minor components are precisely measured and mixed. These materials are chosen for their purity to ensure the final glass product is free from imperfections and has optimal clarity.

- Melting: The raw material batch is fed into a large furnace, where it is melted at extremely high temperatures (around 1500°C) to form molten glass. This stage requires precise temperature control and a controlled atmosphere to prevent impurities.

- Patterning (Rolling): The molten glass is then fed between two patterned rollers. One roller typically has the Nashiji texture engraved upon its surface, while the other might be smooth, or both may be patterned depending on the desired outcome. The precise spacing of these rollers determines the final thickness of the glass (e.g., 3mm or 4mm). This is the critical step where the characteristic obscure pattern is imparted onto the glass surface.

- Annealing: After patterning, the newly formed glass ribbon moves into an annealing lehr. This is a controlled cooling process where the glass is gradually cooled from high temperatures to room temperature over an extended period. Annealing relieves internal stresses that develop during rapid cooling, making the glass less prone to thermal shock and breakage, and significantly improving its mechanical strength and dimensional stability.

- Cutting and Finishing: Once annealed, the continuous glass ribbon is automatically cut into large sheets according to standard sizes. These sheets then undergo edge grinding, washing, and inspection for quality control.

- Quality Control and Testing: Throughout the entire process, rigorous quality control measures are in place. This includes visual inspection for defects, measurement of thickness and dimensions, and optical tests for light transmission and obscurity. Finished products are tested against international standards like ISO 9001 for manufacturing quality, and potentially ASTM C1036 (Standard Specification for Flat Glass) or EN 572-5 (Glass in building – Basic soda-lime silicate glass products – Patterned glass) for product specifications.

Fig 1: Schematic representation of patterned glass manufacturing, highlighting the rolling process.

The service life of properly installed and maintained 3mm 4mm Nashiji obscure pattern glass can exceed 20-30 years in typical indoor applications, demonstrating its durability and long-term value.

Application Scenarios

The unique properties of 3mm 4mm Nashiji obscure pattern glass make it highly suitable for a diverse range of applications across various industries and settings:

- Residential Applications:

- Bathroom Glazing: Shower screens, cubicle doors, and window panes where privacy is paramount.

- Internal Doors and Partitions: Creating separation between rooms while allowing natural light flow, such as kitchen pantry doors, living room dividers, or bedroom entryways.

- Furniture Elements: Cabinet doors, tabletops, and decorative inserts in wardrobes, adding a touch of elegance and visual interest.

- Balcony Railings: When tempered, it provides privacy for balconies or terraces without blocking light.

- Commercial and Office Applications:

- Office Partitions: Dividing workspaces to create private meeting rooms or individual offices, fostering concentration without isolating employees from natural light.

- Conference Room Dividers: Offering visual privacy for sensitive discussions.

- Reception Areas: Used in decorative panels or as part of reception desks to create an inviting yet private atmosphere.

- Retail Storefronts (partial): For displays where goods need to be subtly obscured or for back-of-house areas.

- Industrial and Specialized Applications:

- Greenhouses and Agricultural Buildings: Diffusing harsh sunlight, protecting plants from direct intense radiation, and creating a more uniform light environment.

- Lighting Fixtures: As diffusers in luminaires to soften and spread light.

- Machinery Guards (non-safety critical): Offering a degree of visual separation while allowing general light through.

Fig 2: Example of Nashiji glass in a bathroom partition, providing elegant privacy.

These diverse applications underscore the versatility and functional advantages of this specialized glass product in enhancing both privacy and aesthetic appeal.

Technical Advantages

The choice of 3mm 4mm Nashiji obscure pattern glass offers several distinct technical advantages for specifiers and end-users:

- Enhanced Privacy: The primary advantage is its high level of visual obscurity. The Nashiji pattern effectively distorts views, making it impossible to see clear images through the glass while still allowing ample natural light to pass, maintaining bright and open-feeling spaces.

- Optimal Light Diffusion: Unlike clear glass, which can create glare and harsh shadows, Nashiji glass diffuses incident light evenly. This creates a softer, more uniform illumination, reducing eye strain and enhancing comfort in interiors. This also contributes to energy saving by reducing the reliance on artificial lighting during daylight hours.

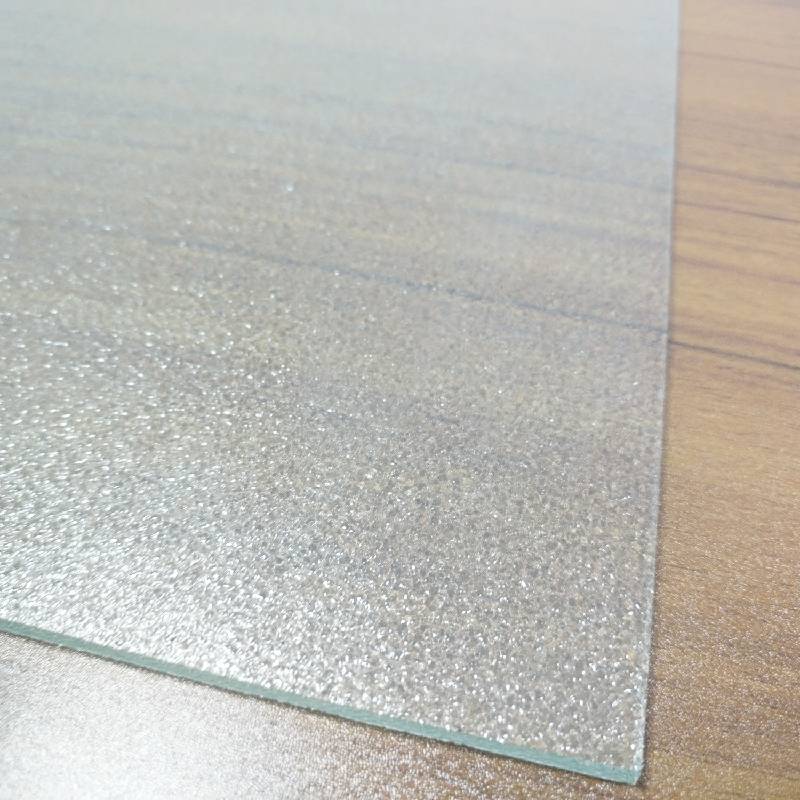

- Durability and Low Maintenance: Being a form of patterned glass, it shares the inherent durability of standard soda-lime float glass. It is resistant to scratches and everyday wear, and its textured surface can actually help conceal smudges or fingerprints better than clear glass, simplifying maintenance. The corrosion resistance of glass itself ensures longevity even in humid environments like bathrooms.

- Aesthetic Versatility: The unique pear-skin texture provides a sophisticated, non-directional aesthetic that complements diverse architectural styles. It adds a subtle design element that can elevate the perceived quality of a space.

- Customization Potential: This glass can be further processed through tempering (for safety), laminating (for enhanced security and sound insulation), or incorporated into double glazing units (for thermal performance), broadening its applicability across demanding projects.

These advantages collectively position Nashiji glass as a superior choice for projects requiring a blend of privacy, diffused light, and aesthetic appeal.

Vendor Comparison: Nashiji vs. Other Obscure Patterns

When selecting obscure pattern glass, it is crucial to understand the differences between various patterns. While all obscure glasses provide privacy, their aesthetic, light diffusion characteristics, and suitability for specific applications vary. Here, we compare 3mm 4mm Nashiji obscure pattern glass with common alternatives like Mistlite and Reeded glass.

Comparison Table:

| Feature |

Nashiji Glass |

Mistlite Glass |

Reeded Glass |

| Pattern Description |

Fine, granular, non-directional "pear skin" texture. |

Pebbled, almost raindrop-like texture, typically uniform. |

Vertical or horizontal parallel flutes/ridges. |

| Visual Obscurity |

High (excellent privacy, soft blur). |

Medium-High (good privacy, slightly more distorted view). |

Medium (directional obscurity, some definition visible). |

| Light Diffusion |

Excellent (even, soft, non-directional light spread). |

Good (diffused light, can create some visual 'sparkle'). |

Moderate (directional light bending, can create striations). |

| Aesthetic Appeal |

Modern, subtle, sophisticated; complements minimalist designs. |

Traditional, classic; often used for period or rustic styles. |

Contemporary, linear; creates a sense of height or width. |

| Cleaning Difficulty |

Easy-Moderate (fine texture, generally easy to clean). |

Moderate (deeper texture can trap dirt). |

Easy (smooth flutes, accessible for cleaning). |

Fig 3: Visual comparison of obscure glass patterns (example shown not exact but illustrative).

While Mistlite provides substantial obscurity and Reeded glass offers a distinct linear aesthetic, Nashiji glass excels in delivering a superior balance of high privacy, even light diffusion, and a contemporary, subtle aesthetic that is often preferred in modern designs. The non-directional pattern of Nashiji also makes it easier to work with, as orientation during installation is less critical.

Customized Solutions

Beyond standard sheets, we offer comprehensive customization options for 3mm 4mm Nashiji obscure pattern glass to meet precise project requirements:

- Custom Sizes and Shapes: Glass can be cut to exact dimensions and irregular shapes, including intricate designs for specific architectural features or furniture components.

- Edge Work: A variety of edge finishes are available, including polished, ground, beveled, or custom profiles, to enhance aesthetics and safety.

- Tempering (Toughening): For applications requiring enhanced safety and impact resistance (e.g., doors, shower screens, balustrades), Nashiji glass can be heat-tempered to meet safety standards like ANSI Z97.1 or EN 12150.

- Lamination: Combining two or more Nashiji glass panes with an interlayer (PVB or SGP) creates laminated glass, offering superior security, sound reduction, and UV protection. In case of breakage, glass fragments remain adhered to the interlayer.

- Insulated Glass Units (IGUs): Nashiji glass can be incorporated into double or triple-glazed units for improved thermal insulation and acoustic performance, especially for external windows or demanding interior partitions.

- Low-Iron Options: For projects demanding exceptional clarity and true color rendition, low-iron Nashiji glass is available, minimizing the green tint often found in standard glass.

Fig 4: Custom cutting and finishing processes for specialized glass.

Our team of experts works closely with clients from design conceptualization to final production, ensuring that all bespoke requirements are met with precision and adherence to quality standards.

Application Case Studies

To illustrate the practical benefits and versatility of 3mm 4mm Nashiji obscure pattern glass, consider the following real-world applications:

- Case Study 1: High-End Residential Bathroom Enclosures

A luxury apartment complex opted for 4mm tempered Nashiji glass for all shower screens and privacy partitions in their master bathrooms. The client required high visual obscurity for occupant comfort, coupled with superior light transmission to maintain a bright, airy feel. Nashiji glass provided the perfect solution, enhancing the aesthetic appeal of the bathrooms while meeting stringent safety standards. Customer feedback highlighted the "elegant diffusion of light" and "uncompromised privacy" as key satisfiers.

- Case Study 2: Corporate Office Interior Partitions

A leading technology firm implemented 3mm laminated Nashiji glass for internal office partitions separating individual workspaces and meeting pods. The objective was to create a collaborative environment that still offered visual privacy and reduced acoustic distraction. The laminated Nashiji not only fulfilled the privacy requirement but also improved sound attenuation by an additional 3-5 dB compared to single-pane glass, creating more productive work zones. The client appreciated the contemporary look and practical benefits.

- Case Study 3: Specialty Greenhouse Glazing

An agricultural research facility utilized 4mm Nashiji glass for its experimental greenhouse sections. The primary goal was to achieve uniform light distribution across plant beds, mitigating hot spots and shading effects from direct sunlight. The Nashiji pattern effectively diffused sunlight, reducing direct radiation by up to 20% and leading to more consistent plant growth and reduced instances of sun-scald. This application demonstrated the glass’s effectiveness in controlling light quality for specific environmental needs.

Fig 5: Nashiji glass in an office setting, providing elegant privacy for workstations.

These diverse cases highlight how Nashiji obscure pattern glass consistently delivers on its promise of combining aesthetic appeal with essential functional benefits across various demanding sectors.

Quality Assurance and Certifications

Our commitment to quality is unwavering, ensuring that every sheet of 3mm 4mm Nashiji obscure pattern glass meets the highest industry standards. We adhere to rigorous quality management systems and hold the following certifications:

- ISO 9001:2015 Certified: Our manufacturing processes and quality management system are certified to ISO 9001:2015, ensuring consistent product quality and customer satisfaction.

- CE Marking: Our products comply with relevant European Union directives and standards, indicated by CE marking, signifying conformity with health, safety, and environmental protection standards.

- ASTM Compliance: Our glass products meet or exceed relevant ASTM International standards for flat glass, including optical and physical properties.

- Strategic Partnerships: We collaborate with leading architectural firms and construction companies globally, testament to the trust and reliability placed in our products and services. Our long-standing relationships with partners like [Hypothetical Partner A] and [Hypothetical Partner B] span over [e.g., 15 years].

Our state-of-the-art testing facilities perform comprehensive evaluations, including light transmission, haze measurement, dimensional accuracy, and impact resistance, ensuring every batch meets our stringent internal benchmarks and international regulatory requirements.

Frequently Asked Questions (FAQ)

- Q1: Can 3mm 4mm Nashiji obscure pattern glass be tempered?

A1: Yes, both 3mm and 4mm Nashiji obscure pattern glass can be fully heat-tempered to significantly increase its strength and safety, making it suitable for applications where safety glazing is required, such as shower doors, balustrades, and entrance doors.

- Q2: What is the primary difference between Nashiji and frosted glass?

A2: Nashiji glass achieves its obscurity through a rolled pattern during manufacturing, creating a subtle, pear-skin texture. Frosted glass, typically, is created by acid-etching or sandblasting clear glass, resulting in a smooth, matte finish. While both offer privacy, Nashiji often provides better light diffusion and a different aesthetic texture.

- Q3: Is 3mm 4mm Nashiji obscure pattern glass suitable for outdoor use?

A3: While inherently durable, for outdoor applications exposed to significant weather elements or requiring thermal performance, it is recommended to specify Nashiji glass as part of a laminated or insulated glass unit to enhance its weather resistance, UV protection, and thermal efficiency.

- Q4: How should Nashiji glass be cleaned?

A4: Nashiji glass can be cleaned using standard glass cleaners and a soft cloth or sponge. For textured surfaces, a soft brush may be used to gently remove any debris caught in the pattern. Avoid abrasive cleaners or harsh scrubbing pads that could damage the surface.

Logistics and Support

We understand that reliable logistics and comprehensive support are critical for B2B clients. We strive to provide seamless service from order to delivery and beyond.

- Lead Time & Fulfillment: Standard lead times for 3mm 4mm Nashiji obscure pattern glass are typically 2-4 weeks, depending on order volume and specific customization requirements. We maintain efficient production schedules and a robust supply chain to ensure timely delivery. Urgent orders can be expedited upon request, subject to production capacity.

- Warranty Commitments: We offer a 5-year limited warranty on all our Nashiji patterned glass products against manufacturing defects, delamination (for laminated variants), and significant loss of optical clarity under normal use conditions. Full warranty details are available upon request.

- Customer Support: Our dedicated customer support team is available 24/7 to assist with technical queries, order tracking, and after-sales support. We provide technical consultation for project planning, material selection, and installation best practices.

- Packaging and Shipping: All glass products are meticulously packed in sturdy wooden crates or A-frames, using appropriate interleaving materials to prevent damage during transit. We coordinate with reputable logistics partners to ensure safe and efficient global delivery.

Conclusion

The 3mm 4mm Nashiji obscure pattern glass offers an exceptional combination of privacy, diffused natural light, and refined aesthetics, making it an ideal choice for architects, designers, and builders seeking versatile glazing solutions. Its robust manufacturing process, adherence to international quality standards, and diverse application potential solidify its position as a leading choice in the specialized glass market. With comprehensive customization options and reliable support, we are equipped to meet the nuanced demands of any B2B project, ensuring both functional performance and design excellence.

References

- ISO 9001:2015 - Quality management systems – Requirements. International Organization for Standardization.

- ASTM C1036-16 - Standard Specification for Flat Glass. ASTM International.

- EN 572-5:2004 - Glass in building – Basic soda-lime silicate glass products – Part 5: Patterned glass. European Committee for Standardization.

- The Glass Encyclopedia. Glass and Glazing Federation.

- Building Design + Construction Magazine - Trends in Architectural Glass.