Aug . 26, 2025 00:40

In contemporary architectural and interior design, the integration of bespoke finishes is paramount for establishing unique aesthetic identities. Among these, antique mirror wall panels have emerged as a sophisticated solution, blending historical elegance with modern functionality. These panels, characterized by their distressed, aged appearance, offer a distinct visual texture that standard mirrors cannot replicate. Primarily utilized in high-end commercial, hospitality, and luxury residential projects, they serve not just as reflective surfaces but as decorative art pieces that enhance depth, light, and ambiance.

The manufacturing process for these panels involves specialized techniques to achieve varied patinas, ranging from subtle hazing to prominent oxidation and crackling effects. This meticulous process ensures that each panel possesses a unique character, contributing to an individualized design narrative. From accentuating feature walls in boutique hotels to backsplashes in gourmet kitchens, the versatility and timeless appeal of antique mirror wall panels make them an indispensable asset for designers seeking to infuse spaces with a sense of history and refined luxury.

The market for decorative glass, particularly for products like antique mirror wall panels, is experiencing robust growth driven by several key trends. A significant factor is the increasing demand for customized and high-value interior finishes in both commercial and residential sectors. Designers and architects are continually seeking unique materials that can differentiate projects and convey a sense of bespoke craftsmanship.

Market analysis indicates a steady compound annual growth rate (CAGR) for specialty glass products, with antique mirrors specifically benefiting from their unique aesthetic proposition. According to a report by Grand View Research, the global architectural glass market size was valued at USD 152.92 billion in 2022 and is expected to grow, with decorative glass segments showing particular buoyancy as consumer preferences shift towards customized and aesthetically appealing architectural solutions.

The foundational element of these decorative panels is high-quality float glass, typically in thicknesses of 5mm or 6mm, chosen for its strength, clarity, and dimensional stability. The specific thickness is often dictated by the application's structural requirements and aesthetic preference for edge profile. Our antique mirror wall panels are engineered to meet stringent performance and safety standards.

These panels are often laminated for safety and increased durability, especially in high-traffic commercial environments. Lamination involves bonding two or more glass sheets with an interlayer, typically PVB (Polyvinyl Butyral), enhancing structural integrity and providing a protective barrier against shattering.

The creation of high-quality antique mirror wall panels is a multi-stage process, meticulously controlled to achieve the desired aesthetic and ensure product longevity. Unlike standard mirror production, the antiquing process introduces deliberate imperfections that evoke historical charm.

High-clarity float glass (5mm or 6mm) is selected. CNC precision cutting equipment is used to cut the glass to specified dimensions with tight tolerances, minimizing material waste and ensuring exact panel sizes for architectural integration. This stage adheres to ISO 12543 standards for glass in building.

Edges are machine-ground and polished, beveled, or arris-cut according to design specifications. This step is crucial for safety during handling and installation, as well as for the final aesthetic. Automated grinding and polishing machines ensure consistent edge quality.

The glass surface undergoes an intensive multi-stage cleaning process using demineralized water and specialized detergents. This removes any contaminants that could interfere with adhesion of the silvering layer, ensuring a pristine surface for the subsequent chemical deposition. Adherence to cleanliness is critical for optimal mirror longevity.

A silver nitrate solution is chemically deposited onto one side of the glass. This process, known as silvering, forms the reflective layer. Precise control over solution concentration, temperature, and application speed is essential for uniform silver deposition. This forms the base reflective layer before antiquing begins.

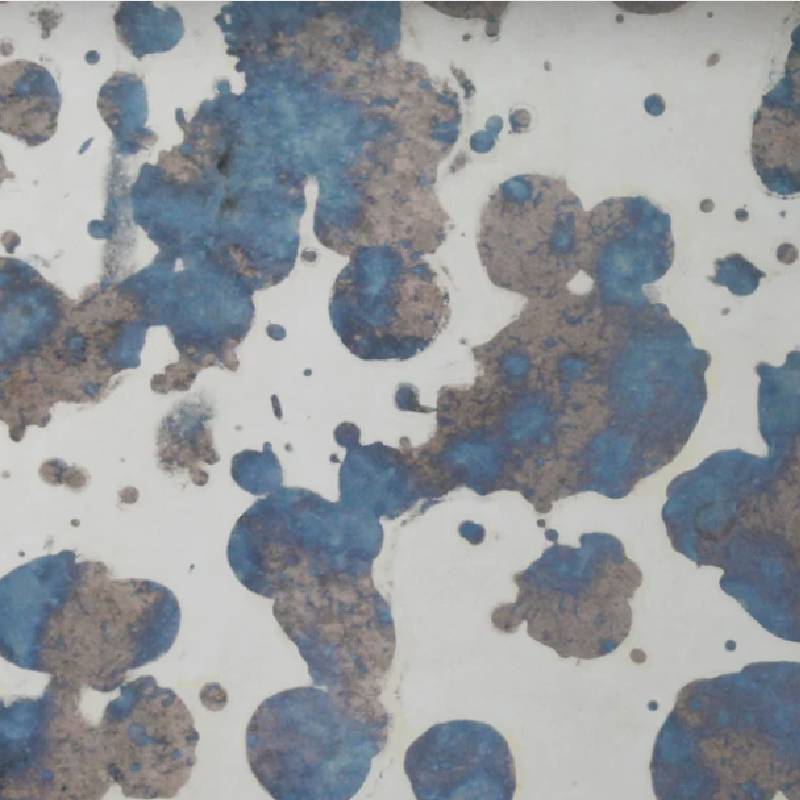

This is the defining stage. The fresh silver layer is treated with various oxidizing agents and chemical solutions. These agents selectively corrode and distress the silver, creating the desired "aged" look, which can include speckling, crackling, veining, or clouding effects. The skill of the technician and the precise chemical formulations dictate the unique patina of each panel. Different patterns and intensities are achieved by varying chemical compositions and application methods, often proprietary.

A high-quality, corrosion-resistant paint (e.g., Fenzi paint) is applied over the antiqued silver layer. This paint protects the delicate silver and patina from environmental factors, moisture, and chemical exposure, significantly extending the mirror's service life. Double coating is often employed for enhanced durability, meeting or exceeding EN 1036-1 standards for coated glass.

The protective paint layer is cured in controlled ovens, ensuring strong adhesion and resistance to scratching and chemicals. This improves the overall robustness of the antique mirror wall panels.

Each panel undergoes rigorous inspection for aesthetic consistency, dimensional accuracy, and coating integrity. Tests may include adhesion tests, moisture resistance tests (per ASTM D2247), and visual inspection under varied lighting conditions to ensure the antiqued effect is consistent with client specifications. We adhere to ANSI Z97.1 and CPSC 16 CFR 1201 safety glazing standards.

For enhanced safety and structural integrity, especially in public spaces, panels can be laminated. This involves bonding the antiqued mirror to another glass sheet or a backing material using a PVB or EVA interlayer under heat and pressure. Laminated antique mirrors meet safety glazing codes, offering improved impact resistance and shatter retention.

Finished panels are carefully packaged in robust, custom-built crates or frames to prevent damage during transit, especially for international shipping. Each package is clearly labeled with product specifications and handling instructions.

The versatile aesthetic of antique mirror wall panels makes them suitable for a myriad of high-end commercial, hospitality, and luxury residential applications. Their ability to subtly reflect light and add character without the starkness of a traditional mirror is highly valued in sophisticated design schemes.

Antique mirrors are frequently used for feature walls, bar backsplashes, and decorative inserts in hotel lobbies, fine dining establishments, and upscale lounges. The aged appearance adds a sense of grandeur and history, enhancing the luxurious ambiance. For instance, in a dimly lit bar, the soft, diffused reflection of an antique mirror can create an intimate and sophisticated glow, superior to the harsh glare of a standard mirror.

Fashion boutiques and jewelry showrooms utilize antique mirrors to create elegant fitting rooms or display backdrops. They offer just enough reflection for customers while adding a decorative element that complements luxury merchandise, avoiding the unflattering brightness of conventional mirrors. This contributes to a premium shopping experience.

In private residences, these panels are ideal for living room feature walls, dining room accents, and elegant kitchen backsplashes. They can enlarge a space without being overtly reflective, making a room feel more expansive and brighter while adding a unique texture. Their ability to introduce an old-world charm effortlessly integrates with both classic and modern interior designs.

Antique mirror inserts are popular in custom furniture, such as cabinet doors, tabletops, and headboards. This application adds a touch of vintage glamour to bespoke pieces, transforming ordinary furniture into statement items. The panels' durability ensures a long service life, even in frequently used furniture.

Beyond functional reflectivity, they serve as standalone art pieces or integrated decorative elements in wall art installations, creating dynamic visual interest through their unique patterns and light interplay. Their aesthetic versatility rivals that of specialized art glass.

In each of these scenarios, the inherent advantage of antique mirror wall panels lies in their distinctive aesthetic. They offer a softer, more diffused reflection compared to standard mirrors, which can be overly bright or unflattering. This quality helps create a more inviting and sophisticated atmosphere, augmenting the overall design intent while adding value and a unique visual signature to any project.

Our 5mm and 6mm antique mirror wall panels are not merely decorative; they possess distinct technical advantages engineered for longevity and performance in demanding B2B applications.

Through advanced chemical treatments and robust back-coating processes, the antiqued effect is sealed and protected. This prevents further degradation or "black spots" that can occur with inferior products, ensuring the aesthetic remains consistent over decades. Our multi-layer paint system provides superior resistance to moisture, humidity, and common cleaning agents, often exceeding the requirements of ISO 9227 (neutral salt spray test) for corrosion resistance.

The intentional imperfections in the silvering scatter light, creating a softer, more ambient illumination. This diffusion reduces glare and harsh reflections, making spaces feel more inviting and comfortable. Unlike highly reflective standard mirrors that can create visual clutter, antique mirrors subtly expand spaces while adding character. This is particularly beneficial in retail settings where harsh reflections can detract from product presentation.

Manufactured from high-quality float glass, our panels exhibit excellent flatness and dimensional accuracy. This is crucial for seamless installation, especially in large-scale wall cladding projects or when intricate paneling designs are specified. Precision cutting with CNC machinery ensures tight tolerances, facilitating complex architectural integrations.

Beyond standard sizes and patterns, we offer extensive customization options for tint, level of distress, and specific antique patterns. This allows architects and designers to specify unique panels that align perfectly with their project's aesthetic vision, whether it requires a subtle vintage whisper or a dramatic, heavily distressed statement piece. This flexibility is a critical advantage in meeting bespoke design briefs.

For applications requiring enhanced safety, our antique mirror panels can be specified as laminated glass. This involves a robust PVB interlayer that holds glass fragments together upon impact, significantly reducing the risk of injury. This adherence to safety glazing standards (e.g., ANSI Z97.1, CPSC 16 CFR 1201) makes them suitable for high-traffic public areas.

Choosing the right supplier for antique mirror wall panels is crucial for project success, impacting quality, lead time, and overall cost-effectiveness. A thorough vendor comparison should extend beyond mere price, focusing on capabilities, certifications, and support.

Partnering with a manufacturer boasting extensive experience and robust quality controls, exemplified by international certifications like ISO 9001, ensures a consistent, high-grade product. Our commitment to customized solutions and transparent communication throughout the project lifecycle provides a reliable partnership for B2B clients.

Recognizing that every architectural project has unique demands, we specialize in providing tailored antique mirror wall panels solutions. Our capabilities extend far beyond standard offerings, ensuring that designers and architects can realize their precise aesthetic and functional visions.

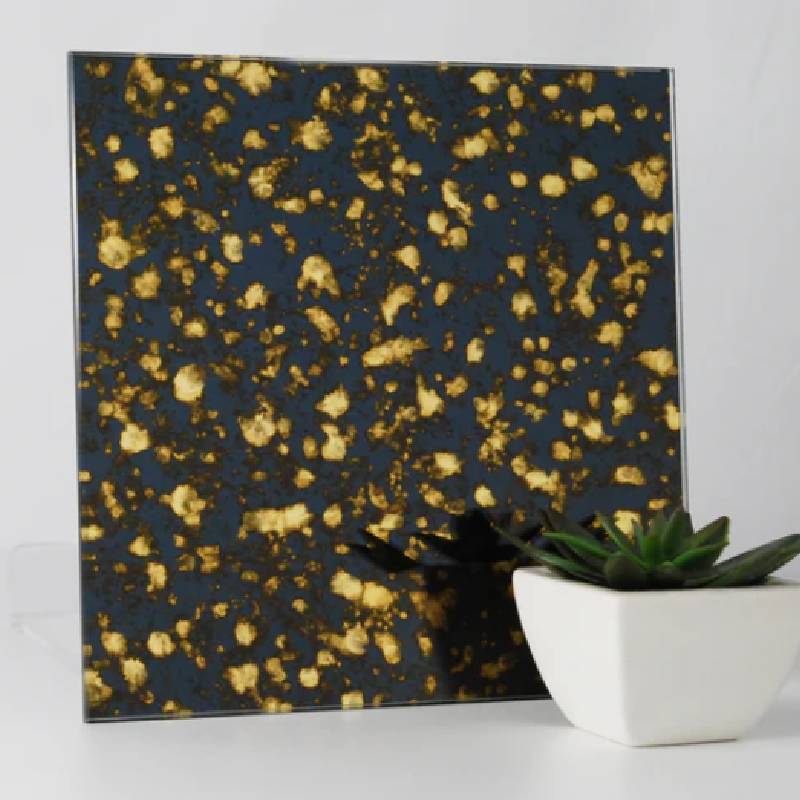

We offer an extensive library of antique patterns, from subtle clouding to pronounced crackle effects. For truly unique projects, our R&D team can work directly with clients to develop custom patina effects and patterns based on concept sketches or material samples. This ensures a truly bespoke finish that perfectly complements the overall design scheme.

Beyond the traditional clear or bronze antique mirror, we can introduce subtle color tints to the glass itself or use custom-colored backing paints to influence the overall hue and depth of the reflection. This allows for integration into specific color palettes, providing a warmer or cooler undertone as required.

Our state-of-the-art CNC machining allows for precision cutting of any shape, size, or complex geometry, including intricate curves, holes for fixtures, or multiple panels forming a larger mosaic. A variety of edge finishes (e.g., polished, beveled, ground) are available to perfectly match the project's design language.

For installations requiring increased safety or structural integrity, we offer lamination with various interlayers (PVB, SGP) and can temper the glass for enhanced strength and thermal shock resistance. These options ensure that the panels not only meet aesthetic goals but also comply with stringent building codes and performance requirements.

Our team provides comprehensive technical consultation, from initial concept development and material selection to detailed installation guidelines. This collaborative approach ensures seamless integration into complex architectural environments and mitigates potential challenges.

Our collaborative process begins with a detailed understanding of the client's design vision and technical specifications, translating conceptual ideas into tangible, high-quality mirror panels that elevate any space.

Client: A leading international hospitality group.

Challenge: The client sought to transform a dated hotel lobby into a sophisticated, art-deco inspired space, requiring unique wall finishes that offered both elegance and visual interest without overwhelming the guest experience. They needed large format panels with a specific, subtle "watermark" antique effect.

Solution: We supplied custom 6mm antique mirror wall panels with a bespoke, lightly distressed "watermark" patina. These panels, measuring up to 1.5m x 3.0m, were precision-cut and installed as a continuous feature wall behind the reception desk and along key walkways. The panels were also laminated for added safety in a high-traffic area.

Result: The antique mirrors created a soft, warm reflection that elegantly diffused the lobby lighting, making the space feel more luxurious and expansive. The subtle antiquing added a layer of historical charm perfectly aligning with the art-deco theme. Customer feedback highlighted the "unparalleled elegance" and "warm, inviting ambiance" attributed directly to the mirror installation. The project was completed on schedule, and the client commended our ability to match their specific aesthetic vision with high-quality, durable products.

Client: A renowned fashion designer opening a new flagship boutique.

Challenge: The client required a distinctive backdrop for their merchandise displays and fitting rooms. They wanted to create a feeling of heritage and luxury, but with modern durability. The key challenge was to ensure minimal visual distortion while providing an aged aesthetic.

Solution: We provided 5mm antique mirror panels with a nuanced "bronze vein" patina. These were cut to bespoke sizes for various display niches and full-height fitting room panels. The bronze tint was critical to complement the boutique's interior palette. Each panel was rigorously inspected to ensure the reflective quality was sufficient for functional use in fitting rooms while retaining the desired antique effect.

Result: The antique mirrors successfully created a sophisticated and unique environment. The bronze veining added a warm, opulent touch, elevating the presentation of the high-fashion garments. The client reported positive customer reactions, with many commenting on the "chic and timeless" interior design. Our team's ability to deliver consistent quality across numerous panels within a tight project timeline was instrumental to the boutique's successful launch.

Our commitment to efficient project delivery begins with transparent lead times. For standard sizes and existing patina patterns, typical production and shipping can range from 15 to 25 business days, depending on order volume and destination. For highly customized solutions or very large project volumes, lead times will be confirmed upon detailed project scope, usually within 4-6 weeks from final design approval. We maintain robust logistics partnerships for reliable global shipping and offer expedited production options for urgent requirements.

We stand behind the quality of our antique mirror wall panels with a comprehensive 5-year limited warranty against manufacturing defects, including delamination of the silvering or back-coating under normal use and proper installation. This warranty reflects our confidence in our materials and manufacturing processes, ensuring peace of mind for our B2B clients.

Our dedicated B2B customer support team and technical specialists are available to assist with every stage of your project, from initial specification and custom design consultation to after-sales support and installation guidance. We offer multi-channel support including email, phone, and online portals, ensuring prompt and expert assistance. Our aim is to build long-term partnerships through unparalleled service and product excellence.

In an architectural landscape increasingly valuing distinctiveness and quality, antique mirror wall panels offer an unparalleled solution for creating truly memorable spaces. Their fusion of timeless aesthetic appeal with modern manufacturing precision and durability makes them a preferred choice for discerning designers and developers. By understanding the intricate manufacturing process, diverse application advantages, and comprehensive customization options, B2B stakeholders can confidently select and integrate these panels to elevate their projects, ensuring enduring beauty and functional excellence.

Ultra Clear Low Iron Glass: High Light Transmission Solutions

NewsAug.28,2025

Unveiling Tempered Glass: The Invisible Armor Guarding Your Modern Life

NewsAug.27,2025

Revolutionizing Modern Architecture with Patterned Solar Glass

NewsAug.22,2025

Low Iron Glazing Elevates Modern Architectural Standards

NewsAug.22,2025

Premium Glass Gaming Mousepad Elevate Your Gaming Experience

NewsAug.22,2025

Acid Etching Glass at Home A Guide to Custom Creations

NewsAug.22,2025