Float glass manufacturing is a fascinating process that has revolutionized the glass industry. This technique, perfected in the mid-20th century, continues to be the dominant method for producing high-quality glass products. As an expert in this field, the journey of float glass from raw materials to end product is nothing short of remarkable.

At the heart of float glass manufacturing is the fusion of raw materials, primarily silica sand, soda ash, and limestone. These materials are meticulously selected for their purity and mixed in precise proportions. The mixture is then heated in a furnace at temperatures exceeding 1700°C. This intense heat transforms the raw materials into a molten glass that is both homogeneous and free of impurities.

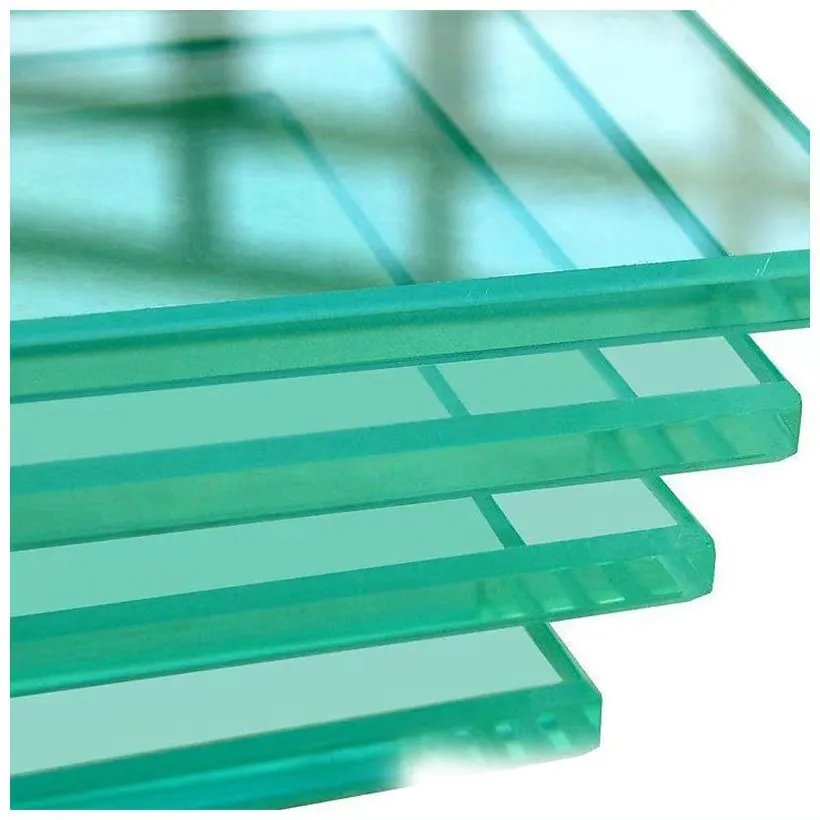

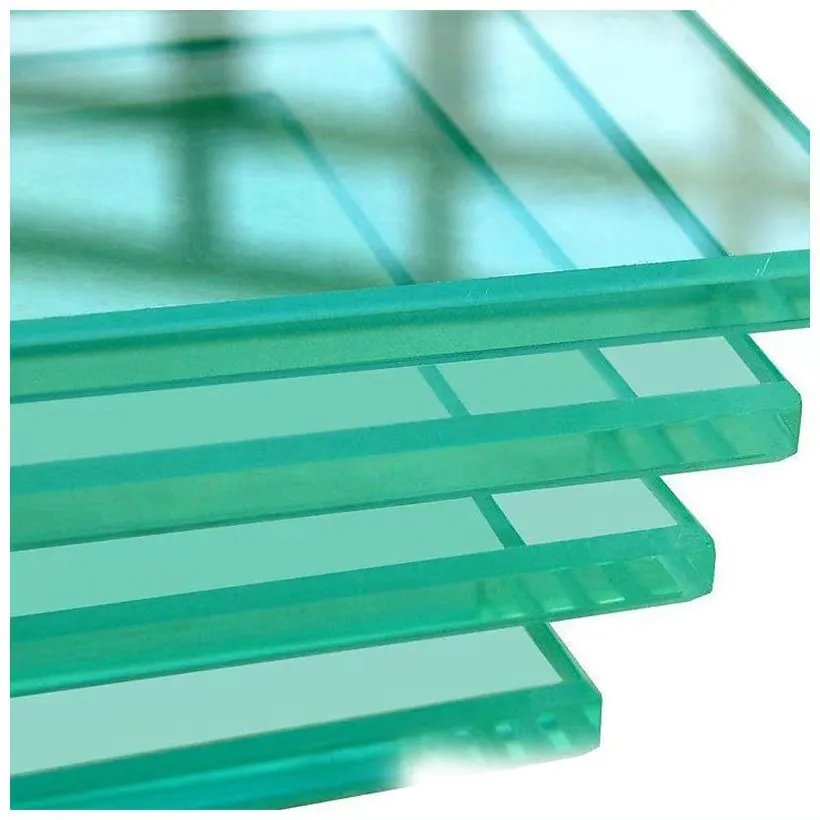

The real ingenuity of the float glass process is in its unique floating technique. The molten glass flows from the furnace into a bath of molten tin. Due to the density difference, the glass naturally floats on the tin, creating an exceptionally flat and uniform surface. This innovative step eliminates the need for mechanical flattening, ensuring that the glass achieves near-perfect clarity and uniform thickness.

Once on the tin bath, the glass is gradually cooled in a controlled environment called the annealing lehr. This cooling stage is critical to relieve internal stresses, ensuring the glass is robust and less prone to brittleness. Precision is key here; too rapid a cooling process can lead to imperfections, while too slow can cause inefficiencies and increased production costs.

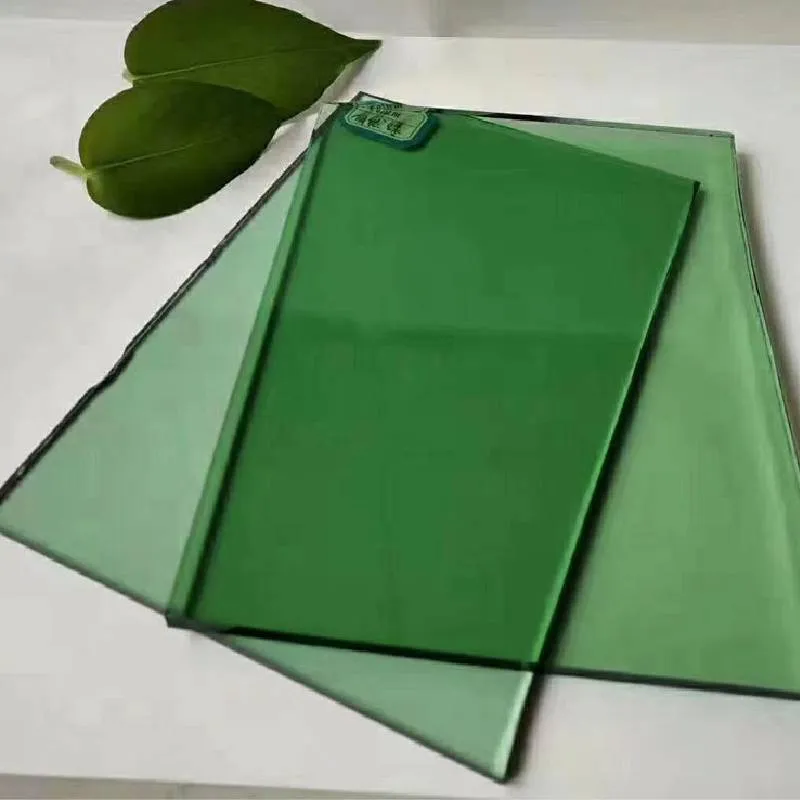

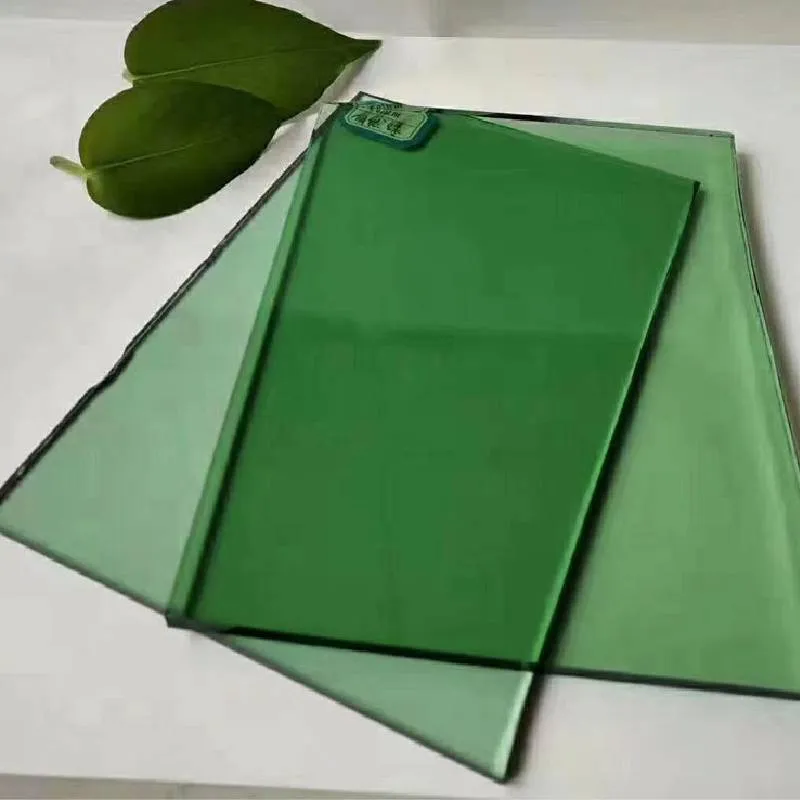

Float glass is not just flat. It is characterized by its excellent optical quality and versatility. It serves as the foundational material for a wide range of specialties in glass products, including coated glass that offers reflective or tinted properties, laminated glass for increased safety, and toughened glass for higher strength. The ability to modify float glass for various applications is one of its defining advantages.

The environmental impact of float glass production has prompted significant innovations aimed at sustainability. Modern plants employ advanced technologies to reduce emissions and energy consumption. Recycling initiatives have also become integral, with cullet—scrap glass from production—being reintroduced into the furnace, decreasing raw material usage and energy demand.

float glass manufacturing

Industry expertise and innovations in automation have further enhanced the float glass manufacturing process. Cutting-edge machinery and robotics ensure precision and efficiency, while real-time monitoring and quality control systems safeguard the integrity of the glass. This integration of technology solidifies float glass manufacturing as a beacon of modern industrial capability.

Trustworthiness in float glass products is established through rigorous certification and testing. Leading manufacturers comply with international standards like ISO and CE, providing assurances of quality and safety. This commitment to maintaining high standards underscores the pride and responsibility that manufacturers uphold in delivering superior glass products.

The use of float glass spans various sectors, including construction, automotive, and interior design. Architects favor it for its aesthetic versatility, while automotive industries rely on its strength and safety features. Interior designers and artists leverage its clarity and beauty in both functional and decorative contexts.

Float glass manufacturing continues to evolve, propelled by research and development. Innovations such as smart glass, which alters light transmission properties, exemplify the dynamic capabilities of float glass. These advancements not only enhance the functionality of glass products but also open new doors for creative and practical applications.

In conclusion, the float glass manufacturing process embodies an intricate balance of art and science. Its evolution from raw materials to refined end products reflects a legacy of innovation, expertise, and commitment to quality. As industries demand ever-higher standards, float glass remains a pivotal component, poised to meet the diverse challenges of today and tomorrow.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu