Float glass manufacturing is a process rooted in decades of innovation, evolving from the historical methods of glass production to an efficient and high-quality process that dominates today's market. This method produces flat glass by floating molten glass on a bed of molten tin. The process not only ensures uniform thickness and flatness but also enhances the clarity and brilliance of the final product, making it indispensable in various industries such as construction, automotive, and solar energy.

The journey of float glass begins in a furnace where raw materials, primarily silica sand, soda ash, and limestone, are combined. Subjected to temperatures exceeding 1,700 degrees Celsius, these materials transform into a molten glass mixture. The delicate balance of temperature and the precise composition of raw materials highlight the expertise required in this field, as any deviation can affect the quality of the glass.

Once molten, the glass is fed continuously onto a bath of molten tin under a carefully controlled atmosphere. Here, it achieves a perfectly flat surface, owing to the glass' natural tendency to spread and the perfectly flat nature of the tin. As the glass floats along this bath, its thickness can be controlled by manipulating the speed at which it is drawn off. This level of precision demonstrates the advanced technological expertise embedded in the float glass manufacturing process, ensuring products meet specific industry standards.

As the glass exits the tin bath, it enters a controlled cooling environment known as the annealing lehr. This stage is crucial, as it gradually reduces the temperature of the glass, relieving internal stresses. If not correctly annealed, glass could develop weaknesses that compromise its structural integrity. Therefore, expertise in temperature regulation and an understanding of glass properties are pivotal. This ensures that the final product is not only pristine in appearance but also robust and reliable.

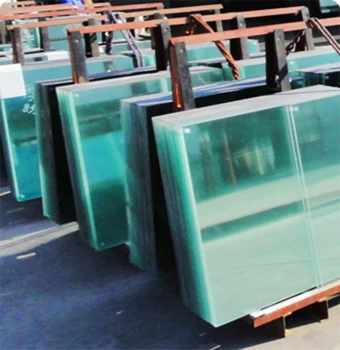

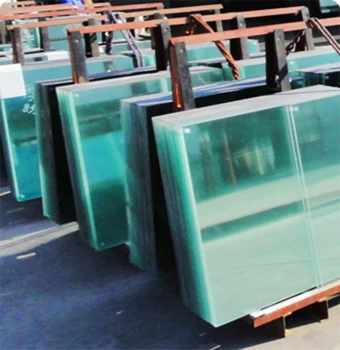

float glass manufacturing

Float glass manufacturing underscores its authority within the glass production industry by consistently delivering a product perfectly suited for various applications. Whether it’s for the sleek façade of a skyscraper offering superior light transmittance and energy efficiency, the windshield of a car requiring durability and clarity, or components in photovoltaic panels heralding the era of renewable energy, float glass proves its versatility and utility.

Trustworthiness in float glass is built on stringent quality assurance processes. Each batch undergoes rigorous testing for optical clarity, thickness uniformity, and potential stress points, reassuring consumers of the product's performance. Manufacturers operating within this sector often adopt sustainable practices, incorporating recycled glass (cullet) into their production processes. This not only reduces the environmental footprint but also enhances the furnace's efficiency, addressing modern concerns about ecological impact and resource sustainability.

Given its foundational role in modern architecture and industry, the production of float glass is a testimony to the harmony between tradition and innovation. Manufacturers remain committed to advancing their techniques and technologies, ensuring that the end-users receive a product that meets and often exceeds the highest standards of quality and reliability. This commitment to excellence solidifies float glass manufacturing's position as a leader within the global glass industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu