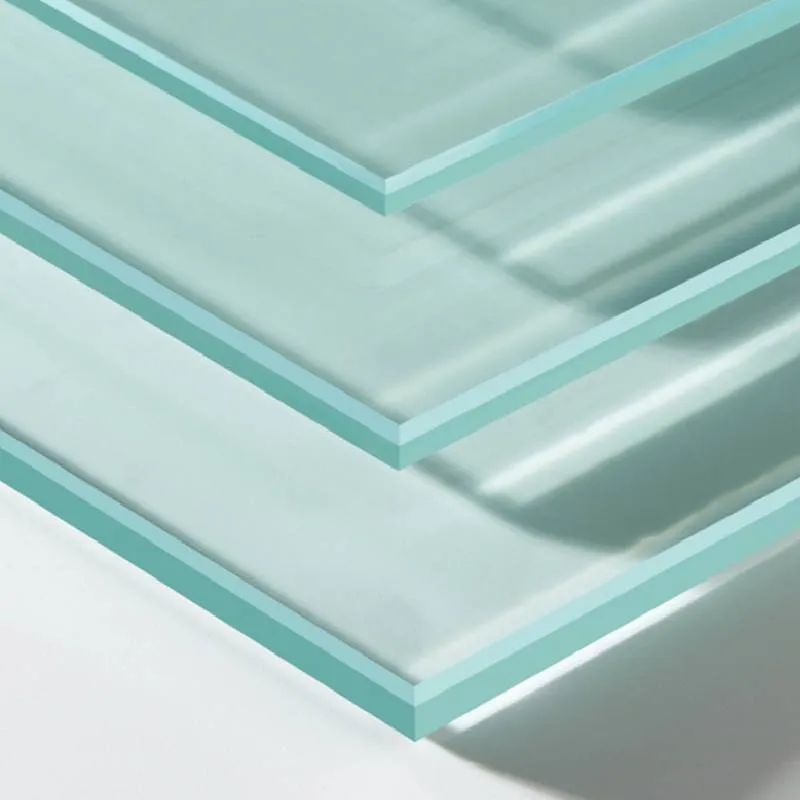

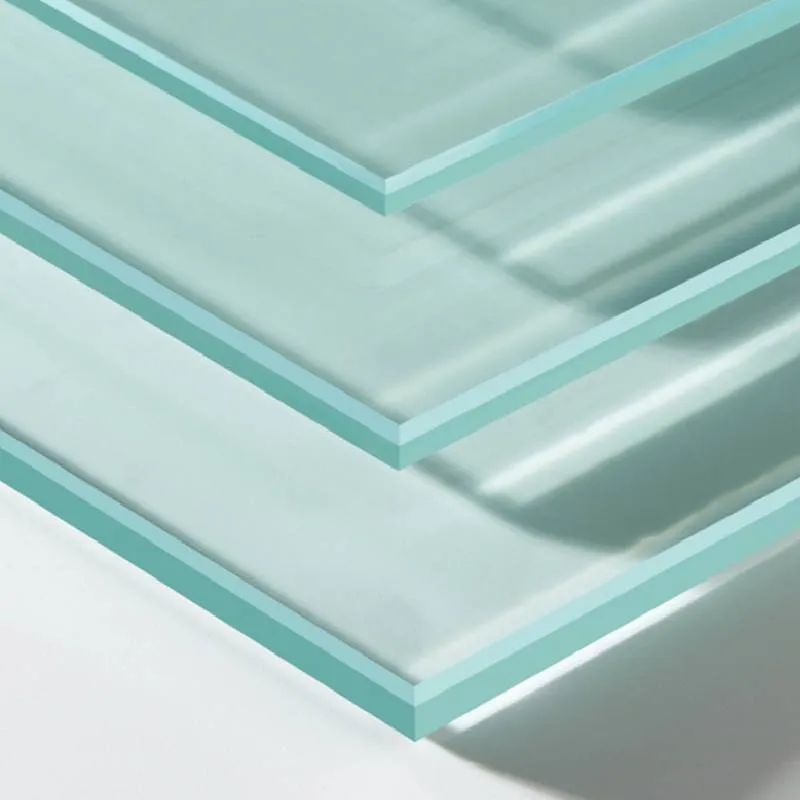

Float glass, a wonder of modern engineering and an essential material in today's diverse market, is a testament to innovation in the glass manufacturing industry. As one of the most commonly used types of glass, it plays a crucial role in a multitude of applications ranging from architectural marvels to daily household items. This article delves deep into the fascinating world of float glass, exploring its meaning, production process, and its significance across various industries.

At its core, float glass refers to a type of flat glass that is crafted using a high-precision method known as the float process. This technique, developed in the 1950s by Sir Alastair Pilkington and Kenneth Bickerstaff, revolutionized glass manufacturing. The float process entails floating molten glass on a bed of molten tin, allowing the glass to spread and form a smooth surface naturally. This process results in glass with uniform thickness and exceptional optical clarity, properties highly valued in both commercial and residential applications.

In terms of experience, many in the industry appreciate the versatility of float glass. Its adaptability is evident in its use as window panes in skyscrapers, where the demand for structural integrity and aesthetic appeal is paramount. Additionally, homeowners have increasingly opted for float glass in modern interior design, using it in shower enclosures, tabletops, and decorative features. This material's durability and the ease with which it can be cut, tempered, or laminated allow designers to push the boundaries of creativity without sacrificing safety or functionality.

From an expertise perspective,

the production of float glass requires specialized knowledge and precision engineering. The process begins with the careful selection of raw materials, typically sand, soda ash, and limestone. These materials are melted in a furnace at temperatures reaching up to 1700 degrees Celsius. The molten glass is then directed onto the molten tin bath, where it flows and spreads evenly. Control over temperature and speed is critical to achieving the desired thickness and quality, usually ranging from 0.4mm to 25mm. This entire process takes place in a controlled environment to prevent any distortion or impurities, ensuring that the end product meets stringent industry standards.

float glass meaning

In terms of authoritativeness, float glass has established itself as a fundamental component in construction and manufacturing. It is widely used in producing vehicle windows, furniture, and even solar panels, each application benefiting from float glass's strength and adaptability. Moreover, advancements in float glass technology have led to the development of energy-efficient glass products, such as low-E glass, which significantly reduce energy consumption in buildings. By minimizing heat exchange, these products contribute to environmental sustainability—a testament to the innovative potential of float glass.

Trustworthiness, in both its material qualities and its manufacturers, is a defining characteristic of float glass. Leading companies in the industry adhere to rigorous quality control processes to ensure that each sheet of glass meets safety and performance criteria. Certifications and standards, such as those set by the American National Standards Institute (ANSI) or the European Norm (EN), provide consumers and industry professionals with the assurance that float glass products are both reliable and safe.

Float glass is a pivotal material in today’s world, underpinning advancements in technology and design while maintaining an unwavering commitment to quality and safety. Its production process is a marvel of modern engineering, and its applications are as varied as they are essential. As global demand for sustainable and innovative glass solutions continues to rise, float glass remains at the forefront, poised to meet the challenges and opportunities of tomorrow.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu