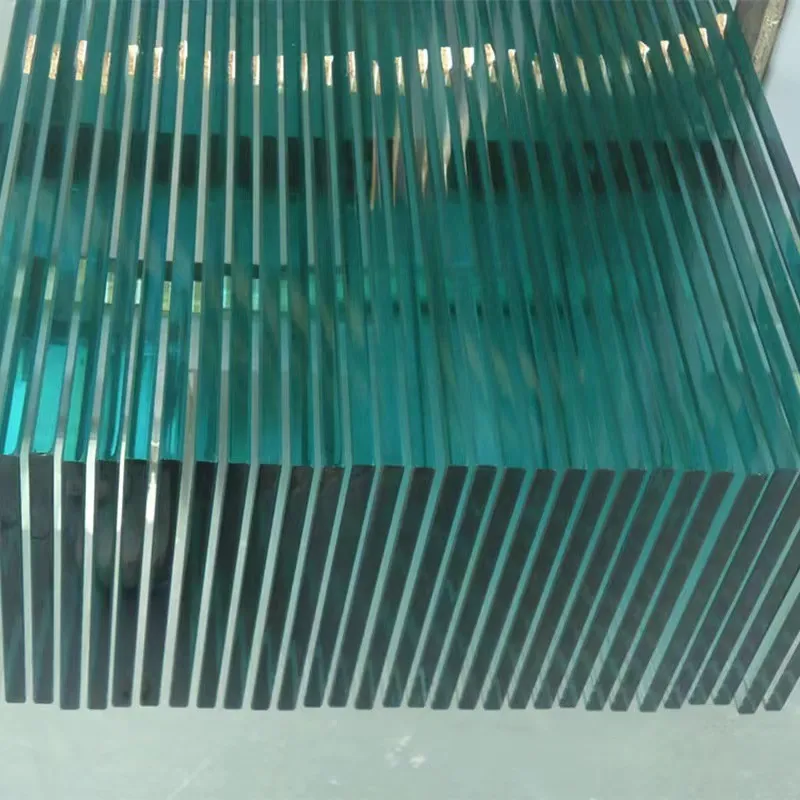

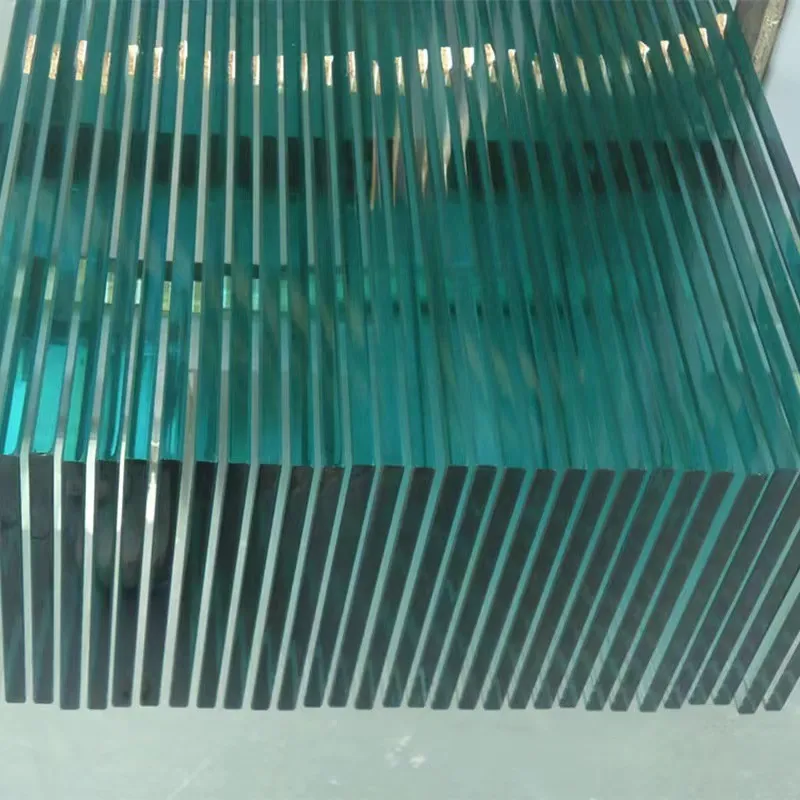

The tempered glass process represents a pivotal advancement in the production of durable and safe glass products. This sophisticated process not only enhances the physical properties of glass but also extends its applications across various industries. As a product expert with extensive experience in glass manufacturing and applications, it is imperative to understand the nuances of this transformative process.

Tempered glass, often synonymous with safety glass, undergoes a meticulous manufacturing process that significantly improves its strength and durability compared to standard glass. The journey begins with the selection of high-quality raw glass, typically of a specific thickness, ensuring uniformity and consistency throughout the processing stages.

The first critical step in the tempered glass process is heating. The raw glass is placed into a tempering furnace where it is gradually heated to temperatures exceeding 600 degrees Celsius. This heating phase is crucial as it prepares the glass for the subsequent rapid cooling, known as quenching. The precision in reaching the optimal temperature ensures that the glass is malleable enough to undergo structural changes without compromising its clarity or transparency.

Quenching, the next phase, is where the tempered glass derives its unique strength characteristics. During quenching, the heated glass is subjected to cool streams of air, rapidly cooling the outer surfaces while the inner layers remain hotter for a longer duration. This differential cooling creates compressive stresses on the surface and tensile stresses within the interior, endowing the glass with enhanced resistance to mechanical forces and thermal shocks. This phase demands exceptional expertise and precision as the cooling rate directly influences the glass's final mechanical properties.

Furthermore, the process of tempering confers another essential safety characteristic shattering behavior. Unlike ordinary glass, which can fracture into sharp shards, tempered glass breaks into small, blunt pieces, significantly reducing the risk of injury. This property makes tempered glass an ideal choice for applications in automotive, architectural, and consumer electronics sectors where safety is paramount.

tempered glass process

The expertise in executing the tempered glass process also involves rigorous quality control measures. Throughout the production cycle, the glass undergoes continuous inspections to detect any micro-cracks, distortions, or surface imperfections. Adherence to international standards ensures that the final product not only achieves but exceeds the expected benchmarks of performance, reliability, and safety.

Implementing the tempered glass process requires a profound understanding of glass chemistry, material science, and the thermal dynamics involved in heating and cooling phases. Professionals in the industry leverage advanced technologies and machinery, such as state-of-the-art tempering furnaces and precision jet air nozzles, to maintain the highest standards of quality and efficiency.

As industry applications expand, tempered glass is celebrated for its functional diversity and aesthetic potentials. Architects and designers increasingly integrate tempered glass into modern infrastructure, leveraging its ability to provide structural support alongside aesthetic finesse. In the realm of consumer electronics, tempered glass screens and back panels offer protection without compromising touch sensitivity or visual quality.

Trustworthiness in the tempered glass industry is essential. Manufacturers commit to transparency in their processes, providing comprehensive documentation and certifications for their products. Regular third-party audits and compliance with safety standards enhance the credibility and reliability of tempered glass products in the marketplace.

Through decades of innovation and refinement, the tempered glass process continues to set benchmarks in safety, functionality, and sustainability. As the demand for resilient materials grows, tempered glass remains at the forefront, embodying the perfect amalgamation of art, science, and technological prowess.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu