The Rate of Toughened Glass Understanding 12mm Variants

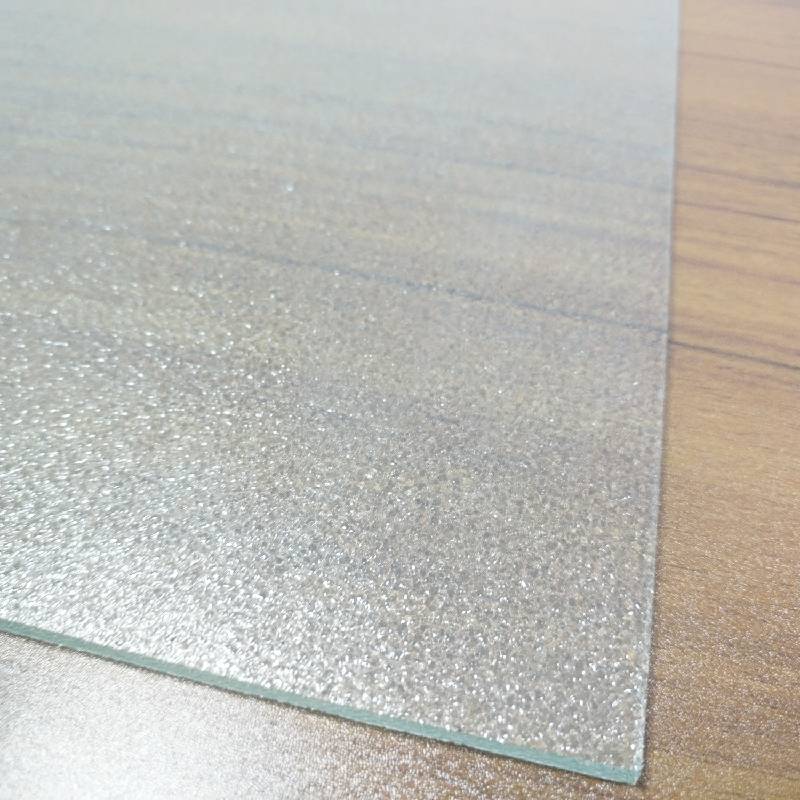

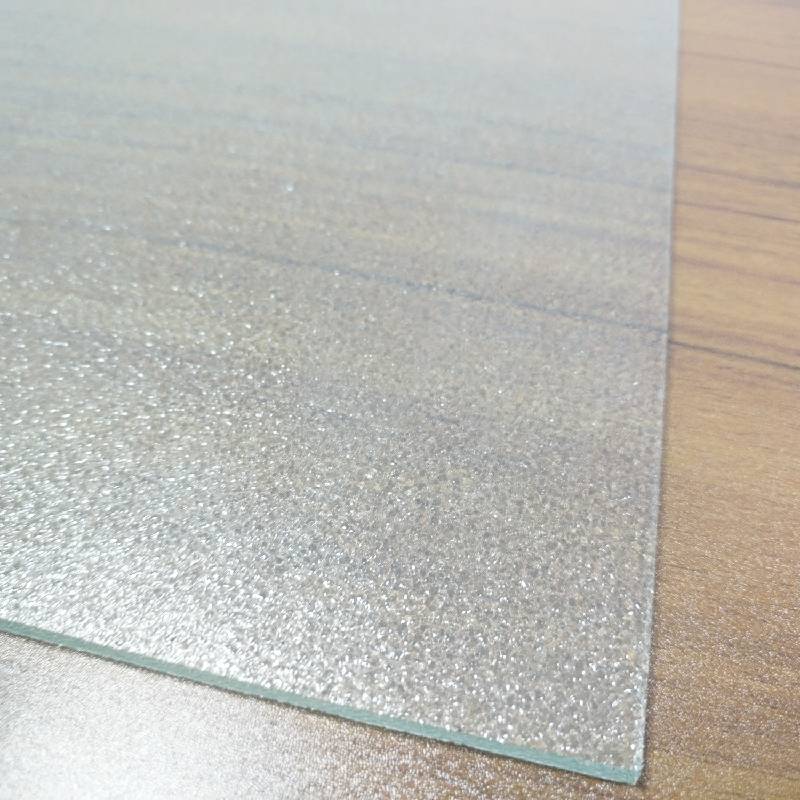

Toughened glass, also known as tempered glass, has become an essential material in various industries due to its increased strength and safety features compared to standard glass. One of the most common thicknesses available in the market is 12mm. Understanding the factors that influence the rate of toughened glass at this thickness is crucial for both consumers and manufacturers alike.

Toughened glass is produced through a process of extreme heating and rapid cooling, which imparts strength and durability. The result is a product that is more resistant to impact, thermal shock, and bending stress. These qualities make 12mm toughened glass ideal for a range of applications, including shower doors, glass facades, kitchen splashbacks, and even structural elements in modern architecture.

The Rate of Toughened Glass Understanding 12mm Variants

Another factor that affects the rate of toughened glass is the procurement of raw materials. The quality of the raw materials used, including the type of silica sand and other additives, can significantly impact the final product. Higher quality materials can lead to better performance, but they also may result in an increased cost. Additionally, fluctuations in global supply chains can cause rates to rise or fall, depending on the availability of these materials.

toughened glass rate 12mm

The demand for toughened glass, especially at the 12mm thickness level, is also influenced by current architectural trends and building codes. As the popularity of modern design grows, there is a corresponding demand for materials that offer enhanced aesthetic appeal and structural efficacy. Architects and designers often specify toughened glass not just for its strength but also for its transparency and ability to create natural light in spaces. Consequently, as demand rises, so may the rates.

Geographical location plays a critical role in the pricing of toughened glass as well. Local regulations, transportation costs, and competition among suppliers can cause significant variations in rates from one region to another. In urban areas where construction activity tends to be higher, the demand for toughened glass may lead to elevated prices. Conversely, in rural areas, a lack of demand may keep rates relatively lower.

Moreover, the technology used in the production of toughened glass also contributes to rate differences. Advances in production methods can streamline manufacturing processes and reduce costs; however, these technologies often require significant initial investments. Manufacturers are often faced with the dilemma of whether to pass these costs onto consumers or absorb them in hopes of gaining market share.

In conclusion, the rate of 12mm toughened glass is determined by a confluence of factors, including production scale, raw material quality, regional demand, and technological advances. As industries continue to evolve and demand for high-strength, aesthetically pleasing materials increases, understanding these dynamics will become increasingly important for stakeholders. Consumers and businesses alike must remain informed about these influences to make educated purchasing decisions in a competitive and ever-changing market landscape.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu