Tempered glass quality is of paramount importance when it comes to ensuring the safety and durability of various products and structures. Tempered glass is a type of safety glass that is processed by controlled thermal or chemical treatments to increase its strength compared to normal glass. This makes it ideal for use in a wide range of applications, including windows, doors, shower screens, and more.

When it comes to assessing the quality of tempered glass, there are several key factors to consider. One of the most important factors is the uniformity of the tempering process. For tempered glass to be effective, it must undergo a controlled cooling process that results in uniform stress distribution throughout the glass. Any inconsistencies in this process can lead to weak spots in the glass, compromising its strength and safety.

Another important factor to consider is the thickness of the tempered glass. Thicker glass tends to be stronger and more resistant to breakage compared to thinner glass. When choosing tempered glass for a particular application, it is important to select the appropriate thickness based on the specific requirements of the project.

In addition to uniformity and thickness, the quality of the raw materials used in the production of tempered glass is also crucial. High-quality raw materials are essential for producing tempered glass that is free from defects and impurities, which can weaken the glass and impact its performance High-quality raw materials are essential for producing tempered glass that is free from defects and impurities, which can weaken the glass and impact its performance

High-quality raw materials are essential for producing tempered glass that is free from defects and impurities, which can weaken the glass and impact its performance High-quality raw materials are essential for producing tempered glass that is free from defects and impurities, which can weaken the glass and impact its performance

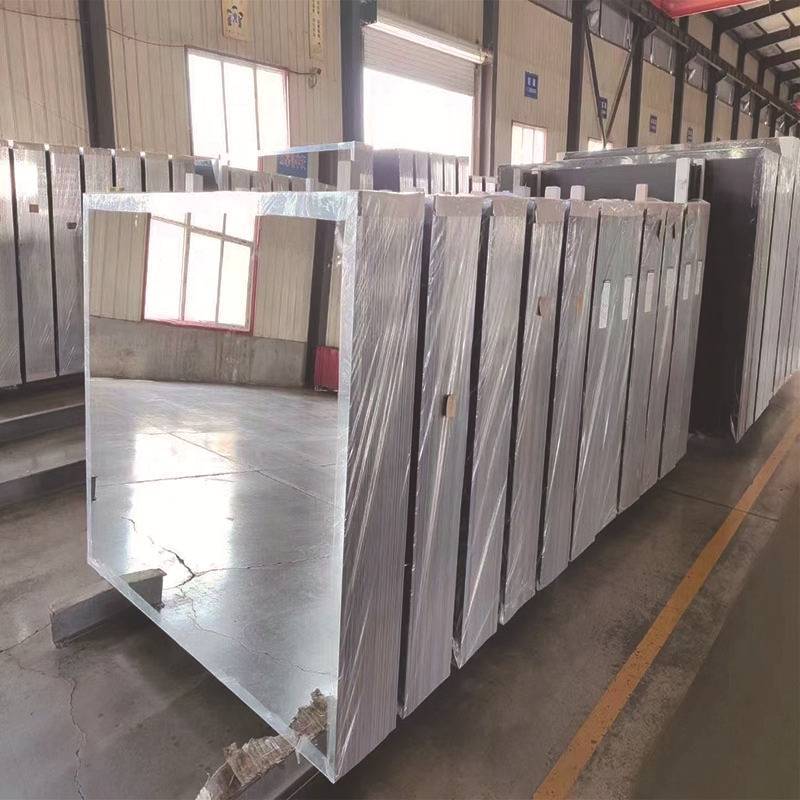

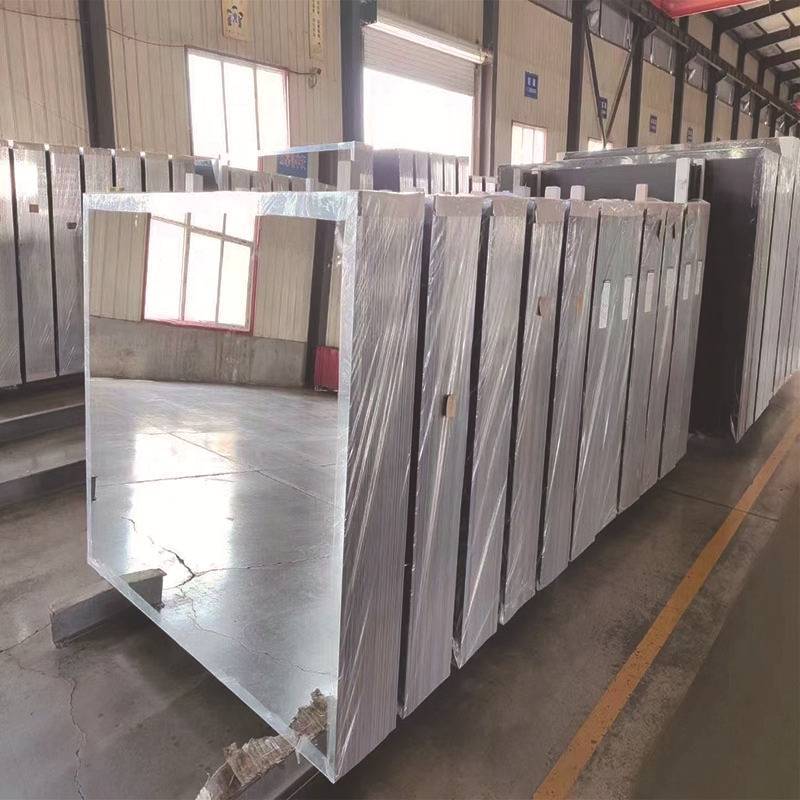

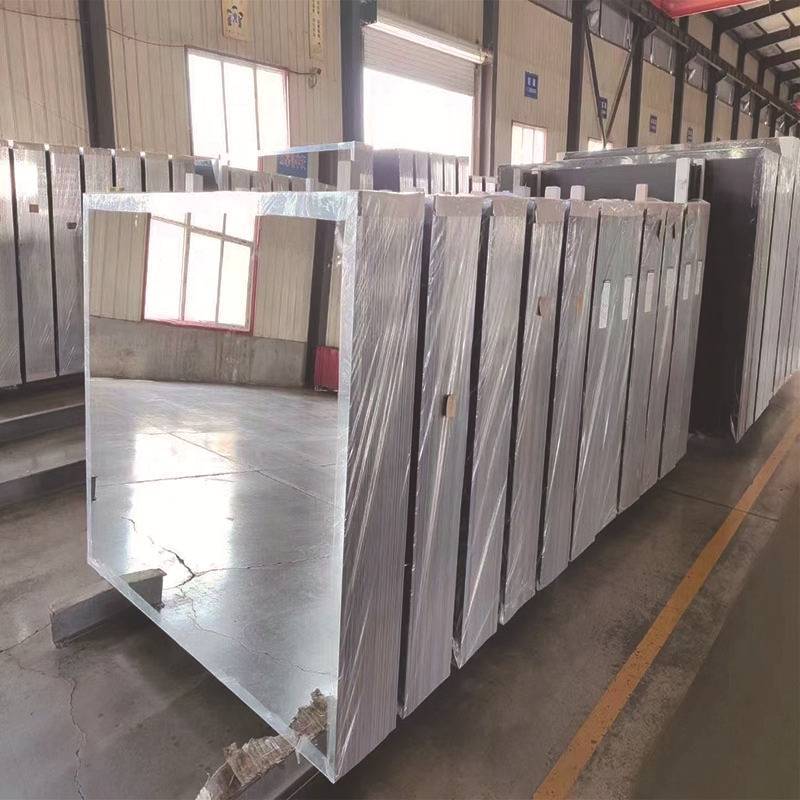

tempered glass quality

tempered glass quality.

Furthermore, the tempering process itself plays a critical role in determining the quality of tempered glass. The glass must be heated to a specific temperature and then rapidly cooled to induce compression stresses on the surface and tension stresses in the interior. This process is what gives tempered glass its strength and durability. Any deviations from the prescribed tempering process can result in glass that is weaker and more prone to breakage.

It is also important to consider the reputation and track record of the manufacturer when evaluating tempered glass quality. Reputable manufacturers with a history of producing high-quality tempered glass products are more likely to adhere to strict quality control standards and provide products that meet or exceed industry requirements.

In conclusion, the quality of tempered glass is a crucial factor to consider when selecting glass for any application. By ensuring that tempered glass undergoes a uniform tempering process, is of the appropriate thickness, is made from high-quality raw materials, and is produced by a reputable manufacturer, you can be confident in the strength, safety, and durability of the glass. Investing in high-quality tempered glass can provide peace of mind and ensure the long-term performance of your products and structures.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

High-quality raw materials are essential for producing tempered glass that is free from defects and impurities, which can weaken the glass and impact its performance High-quality raw materials are essential for producing tempered glass that is free from defects and impurities, which can weaken the glass and impact its performance

High-quality raw materials are essential for producing tempered glass that is free from defects and impurities, which can weaken the glass and impact its performance High-quality raw materials are essential for producing tempered glass that is free from defects and impurities, which can weaken the glass and impact its performance