Understanding the fluctuating cost of float glass is crucial for businesses involved in architecture, automotive manufacturing, and interior design. Float glass serves as a fundamental component due to its versatility and high clarity. This article dives deep into the factors affecting the cost of float glass, providing insights based on expert industry analyses and market trends.

Float glass is produced by floating molten glass on a bed of molten tin, creating a smooth surface. This process implies precise technological nuances and raw material requirements. The primary ingredients include silica sand, soda ash, and limestone, components whose market prices affect the overall production cost.

Significant changes in the raw material market can directly impact float glass pricing. For example, fluctuations in soda ash availability due to geopolitical tensions or environmental regulations can prompt cost variations. Additionally, energy consumption during the production process is substantial, meaning that shifts in energy prices can also ripple into the market price of float glass.

The continuous advances in technology are pivotal but bring mixed effects on costs. Innovative production techniques enhance quality and reduce waste, potentially lowering prices. However, the initial investment in modern equipment can amplify costs in the short term. This dichotomy represents a balance that manufacturers strive to maintain, navigating between long-term efficiency and present expenses.

Industry experts assert that regional demand greatly affects pricing. In areas where construction booms, such as South East Asia, the demand for float glass surges with developmental projects leading to higher local prices. Conversely, in regions with stagnant growth, prices might stabilize or even decrease due to an oversupply.

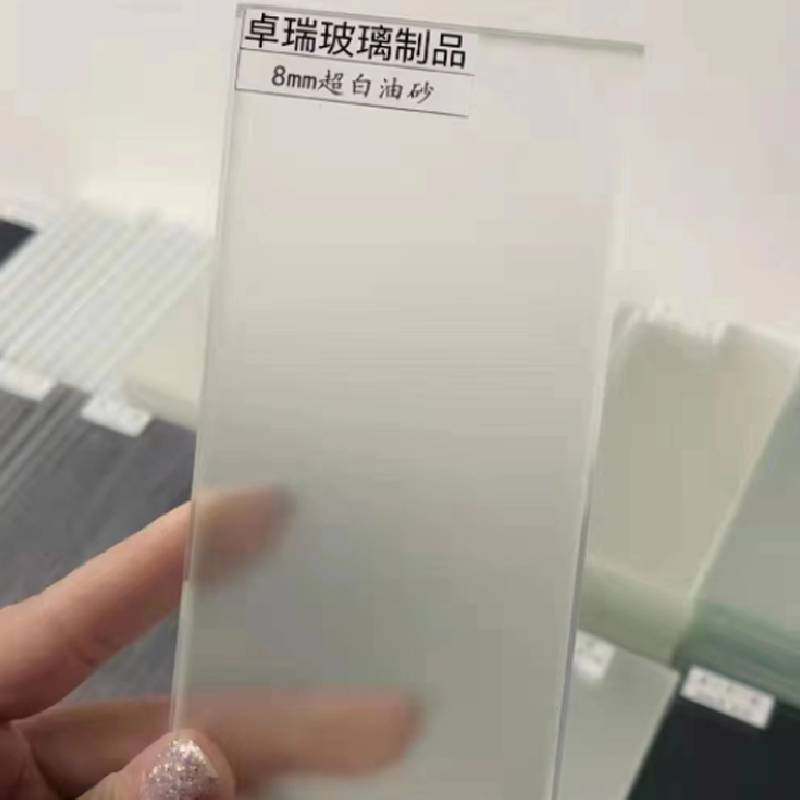

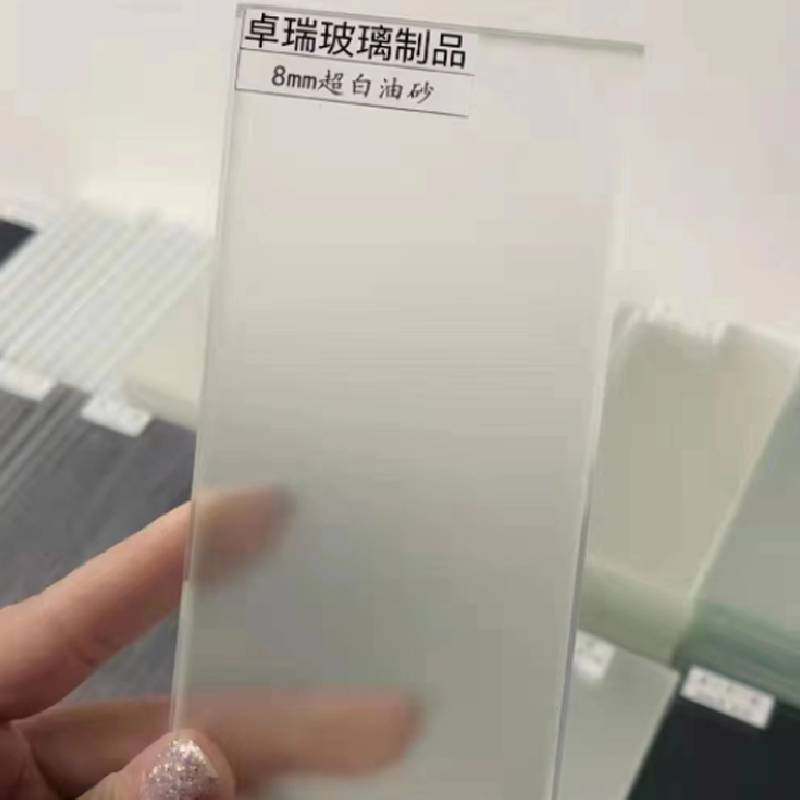

cost of float glass

Additionally, sustainability practices also play a role. The glass industry is moving toward eco-friendly solutions, meeting regulatory demands and reducing carbon footprints. These initiatives, while commendable, often involve upfront costs that can escalate product prices. Thus, businesses are encouraged to strategize carefully, incorporating these aspects without compromising their budgetary allocations.

Supply chain complexities further compound cost considerations. Global supply chains are fraught with potential disruptions, from natural disasters to logistical challenges, ultimately affecting float glass availability and pricing. The recent global COVID-19 pandemic showcased this vulnerability, where disruptions at manufacturing hubs caused a chain reaction impacting glass availability and cost worldwide.

For businesses depending on float glass, understanding these variables is imperative for strategic planning. Diversifying suppliers, opting for long-term contracts, and staying informed about technological advancements can mitigate sudden cost increases.

In conclusion, the cost of float glass is contingent upon a myriad of factors, each requiring careful consideration. By understanding market dynamics and maintaining flexibility, companies can navigate these waters more effectively. As with any material-dependent industry, knowledge, and preparedness are the strongholds of success in managing costs and sustaining competitive advantage.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu