Cutting toughened glass is a meticulous process that demands precision, skill, and the right tools. Unlike standard glass, toughened glass, also known as tempered glass, undergoes a thermal treatment process that makes it significantly stronger and more durable. This ensures safety and longevity in applications such as windows, tabletops, and shower doors. However, these enhanced properties also complicate the cutting process, as improper handling can lead to shattering. This article delves into the expert techniques and tools necessary for successfully cutting toughened glass, while emphasizing experience, expertise, authoritativeness, and trustworthiness.

Understanding the Composition and Properties of Toughened Glass

Toughened glass is four to five times stronger than standard glass, thanks to a heating and rapid cooling method. This process induces compressive stress on the surface, making the glass more resistant to impact and thermal stress. This transformation, however, renders the glass almost impossible to cut once it has been tempered. The cutting must be done before the toughening process, meaning meticulous planning and precision are crucial. Understanding these properties is the first step in ensuring successful cutting and handling of toughened glass.

Pre-Cutting Preparations Accuracy is Key

Before cutting, the glass must be measured and marked with precision. Use a high-quality carbide glass cutter for marking. An expert tip is to use a straight edge made of metal to achieve straight, clean lines. It’s essential to ensure that the environment is dust-free and that the glass is clean to prevent inaccuracies caused by dust particles or residue.

Cutting Techniques Safety and Precision

Since toughened glass must be cut before tempering, experienced professionals approach cutting with accuracy and caution. When planning cuts, ensure that all measurements account for the glass’s installation setting to avoid post-tempering modifications. The cutter needs to apply consistent pressure along the marked lines; any deviation can result in failure.

For those requiring post-tempering modifications, such as installation adjustments, using laser cutting technology is the most reliable method. Laser cutting utilizes focused light to melt and separate the glass, minimizing the risk of shattering and allowing modifications even on tempered glass. This advanced method requires specific expertise, reinforcing the importance of professional intervention.

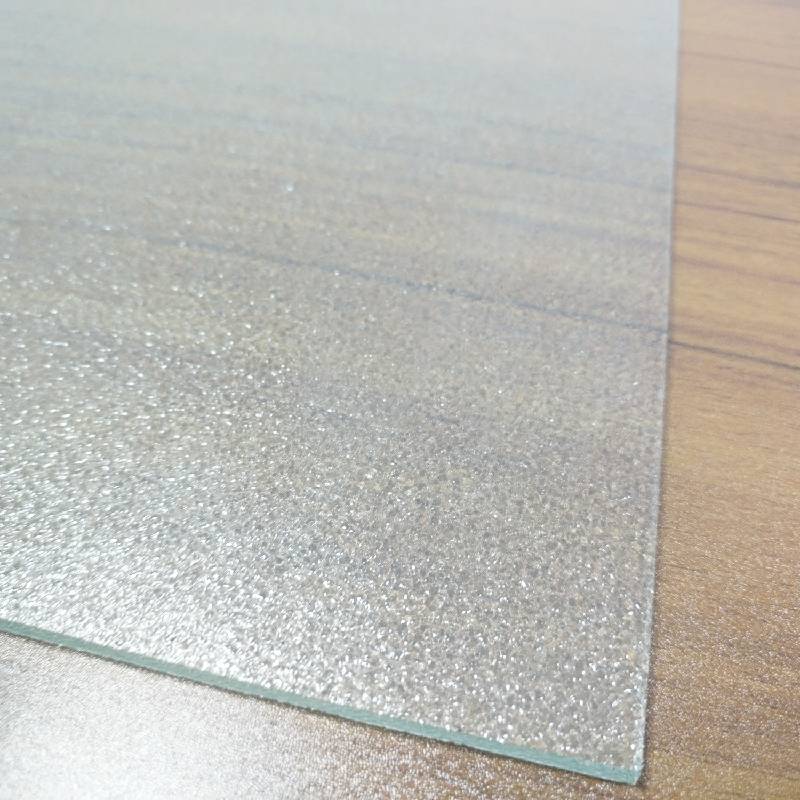

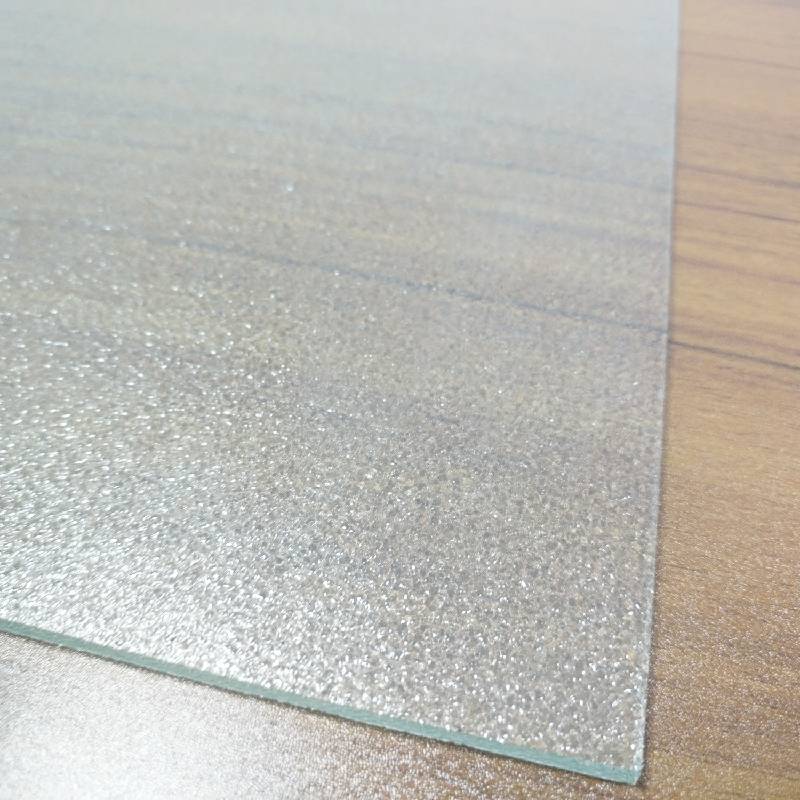

cutting toughened glass

Implementation of Professional Tools and Equipment

Employing the right tools is vital for the precise cutting of toughened glass. Diamond-tipped tools are recommended for their strength and ability to perform clean cuts. Investing in high-quality equipment may seem costly but proves invaluable in preventing wasteful breakage of glass panes.

Safety Integral to the Process

Handling and cutting glass, especially toughened types, involve potential hazards. Safety gear, including gloves, safety goggles, and protective clothing, is non-negotiable. Experts recommend using heavy-duty suction cups for moving glass to mitigate the risk of incidents resulting from slipping or mishandling.

Why Trust Professional Services for Glass Cutting?

The process, complexity, and precision required in cutting toughened glass establish it as an expert-level job. Professionals in this field possess the necessary certification and ongoing training to keep abreast of the latest technological advancements, such as laser cutting. Trust a certified professional who understands the intricacies involved, ensuring safe and efficient results.

Conclusion Expertise Matters

Cutting toughened glass is not a task that should be undertaken lightly. Its complexity requires skilled handling, carefully considered techniques, and the right tools to ensure a solution that is both efficient and safe. Whether planning for pre-tempered adjustments or necessitating post-tempering modifications via methods like laser cutting, the experience and expertise of a qualified professional cannot be overstated. Trustworthiness in this realm is built on a foundation of demonstrated skill, testimonials from satisfied clients, and a proven record of quality and safety. Choose a path that guarantees these outcomes by securing services backed by expertise and a commitment to excellence.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu