Float glass plants are specialized facilities designed to produce high-quality flat glass through a unique manufacturing process known as the float glass process. This method, invented by Sir Alastair Pilkington in the 1950s, revolutionized the glass industry and has become the standard for producing smooth, high-quality glass used in windows, mirrors, and a variety of other applications.

At the heart of the float glass process is the principle of buoyancy. The process begins with the melting of raw materials—silica sand, soda ash, and limestone—at extremely high temperatures in a furnace. This molten mixture of glass is then gently poured onto a bed of molten tin in a large, flat chamber. The tin serves as a liquid platform that allows the glass to spread out evenly, creating a perfectly flat surface. As the glass floats on the tin, it cools and solidifies, retaining its smooth finish without the need for additional polishing.

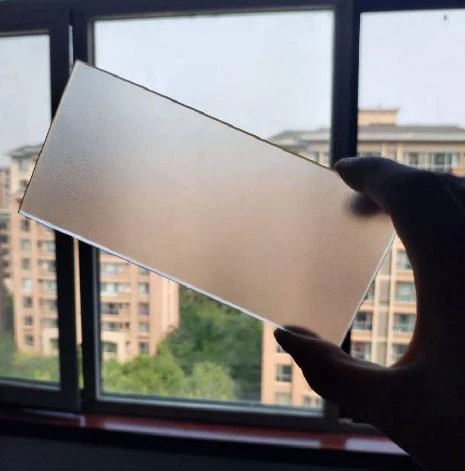

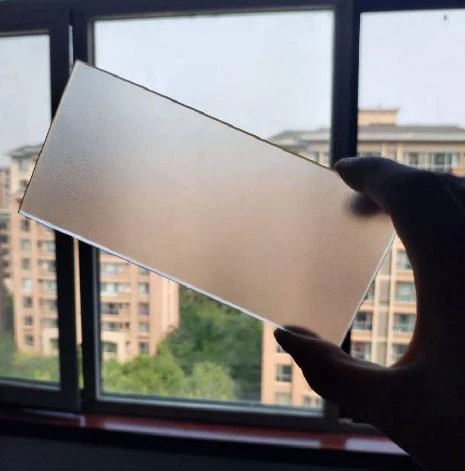

One of the key advantages of float glass is its uniform thickness and clarity, which is essential for many applications, particularly in the construction and automotive industries. The ability to produce large sheets of glass with consistent quality has made float glass a preferred choice over traditional glass manufacturing techniques. These large sheets can be cut to size for various uses, from residential windows to commercial storefronts.

Float glass plants are often designed with high efficiency in mind. They incorporate advanced technologies to minimize energy consumption and reduce waste. The continuous nature of the float glass process, combined with automated systems for monitoring and controlling production parameters, enables manufacturers to achieve high output levels while maintaining stringent quality standards. The development of environmentally friendly practices has also been a focus within the industry, leading to innovations that reduce emissions and energy usage.

float glass plants

Moreover, the versatility of float glass makes it suitable for various applications beyond simple glazing. It can be treated or coated to enhance its properties. For example, low-emissivity (low-E) coatings are applied to improve energy efficiency by reflecting heat back into buildings, thus reducing heating and cooling costs. Additionally, float glass can be laminated to improve safety or tempered to increase its strength and durability. These modifications expand the range of applications for float glass, making it a critical component in modern architecture and design.

The demand for float glass is expected to grow in response to several market trends, including the push for sustainable building materials and increased urbanization. As cities continue to expand and the need for energy-efficient buildings rises, float glass will play a crucial role in meeting these demands. Furthermore, innovations in glass technology, such as smart glass that can change opacity with the application of an electric current, are likely to emerge from float glass production techniques, pushing the boundaries of what glass can do.

In conclusion, float glass plants are integral to the production of flat glass used in a myriad of applications. Their innovative manufacturing processes, commitment to sustainability, and adaptability to new technologies position them at the forefront of the glass industry. As the world continues to evolve, the importance of high-quality, efficient, and sustainable glass production will only increase, making float glass plants essential players in the global market. Through continuous improvement and adaptation, these plants are set to meet the demands of a rapidly changing world while maintaining the high standards of quality and efficiency that have defined the float glass process since its inception.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu