Understanding Tempered Glass Composition and Manufacturing Process

Tempered glass, often referred to as toughened glass, is a type of safety glass that has been treated through controlled thermal processes to increase its strength compared to standard glass. It is commonly used in applications that require enhanced durability and resistance to thermal stress, such as in buildings, vehicles, and appliances. Understanding how tempered glass is made involves exploring its composition and the intricate manufacturing process it undergoes.

Composition of Tempered Glass

Tempered glass is primarily made from silica sand (SiO2), which constitutes the main ingredient of glass. When silica is melted, it undergoes a transformation from a solid to a liquid state, allowing it to be molded into various shapes. However, it doesn’t stop there; additional materials are often added to improve specific qualities of the glass. Common additives include sodium carbonate (soda), potassium carbonate, and calcium oxide, each contributing to the glass's behavior during the melting and forming processes.

In the production of tempered glass, the composition sometimes includes other oxides, like aluminum (Al2O3) and magnesium (MgO), which enhance its thermal and mechanical properties. The mixture of these materials is crucial as it affects the melting temperature and the final characteristics of the glass.

The Manufacturing Process

The journey to creating tempered glass begins with the basic ingredients, which are mixed and melted at high temperatures, typically exceeding 1,000 degrees Celsius (1,832 degrees Fahrenheit). The molten glass is then shaped into flat sheets or other configurations, depending on its intended use. This shaping is generally done using processes like float glass manufacturing, where the molten glass is floated on molten tin to create a smooth surface, or by pressing it into molds.

Once the glass has been formed, it undergoes the tempering process, which is key to its heightened strength. The tempering process involves two main stages heating and rapid cooling, known as quenching.

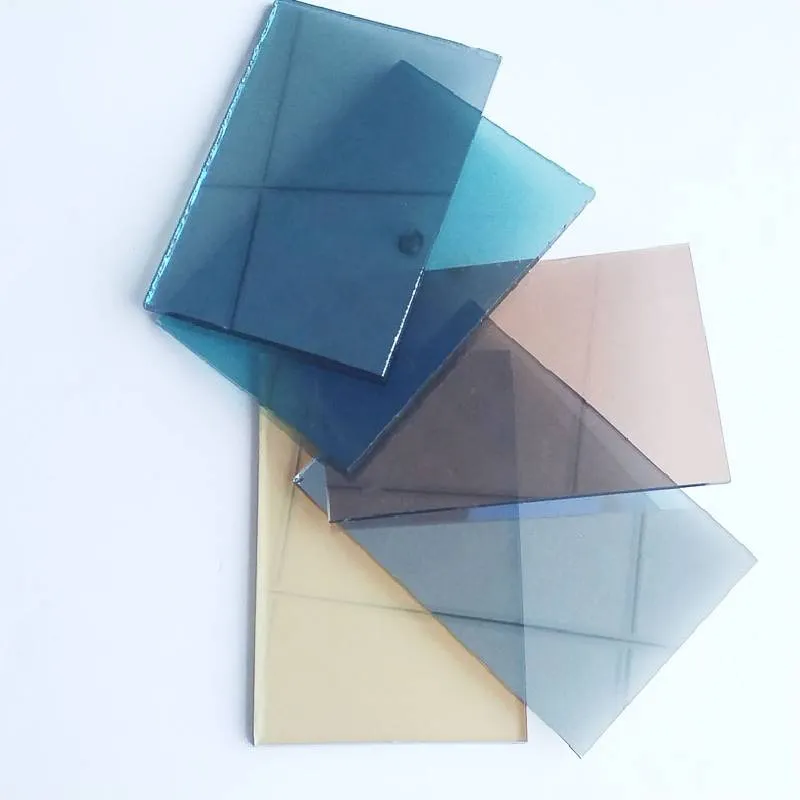

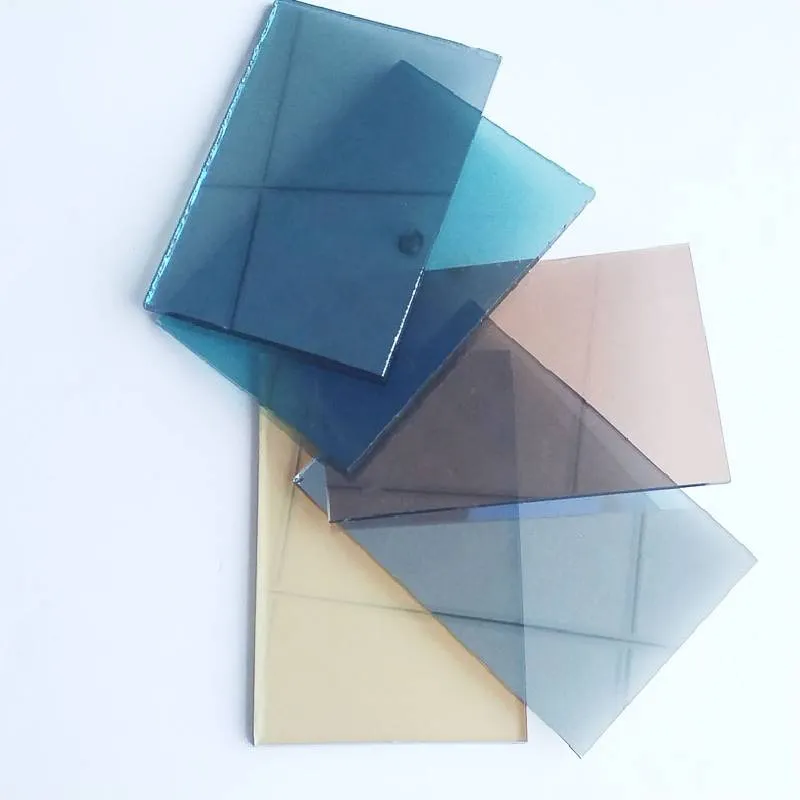

tempered glass is made of

1. Heating The formed glass sheets are heated to a temperature range of approximately 600 to 700 degrees Celsius (1,112 to 1,292 degrees Fahrenheit). This heating process allows the glass to undergo a form of internal stress relieving, preparing it for the next stage of cooling.

2. Quenching After reaching the desired temperature, the glass is rapidly cooled using air jets. This quick cooling solidifies the outer layers of the glass first, while the interior remains hotter for a brief period longer. As the exterior cools and shrinks, it creates a high level of compressive stress on the surface of the glass, while the interior remains in tension. This imbalance in stress is what provides tempered glass its remarkable toughness.

Benefits of Tempered Glass

The resulting tempered glass is about five to six times stronger than regular glass of the same thickness. Its enhanced strength allows it to withstand impact and withstand temperature fluctuations without breaking. In the event of failure, tempered glass shatters into small, blunt pieces rather than sharp shards, reducing the risk of injury.

Due to these characteristics, tempered glass is widely used in architectural applications, such as glass doors, windows, and facades. It is also employed in various household items, including shower doors, glass tabletops, and cooktops, where resilience to heat and impact is critical.

Conclusion

Tempered glass stands out in the realm of glass manufacturing due to its unique properties and the careful process it undergoes. From its raw materials to the intricate heating and cooling methods, the production of tempered glass ensures it meets safety standards and performs exceptionally in demanding environments. As technology advances, tempered glass will continue to play a pivotal role in modern design and construction, enhancing safety and aesthetic appeal in countless applications.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu