Float glass manufacturing is a cornerstone of modern architecture and industrial design, known for its unparalleled quality, transparency, and versatility. This sophisticated process has revolutionized the glass industry, providing a product used widely in constructing homes, buildings, and vehicles. Having worked closely with experts in float glass manufacturing, I can offer a unique perspective on the processes, challenges, and innovation in this sector.

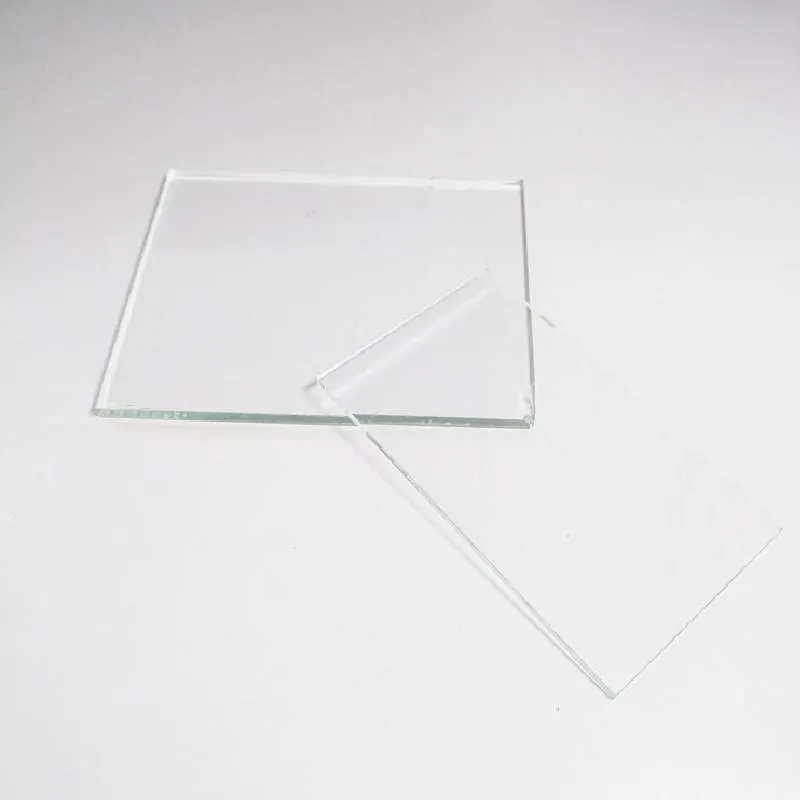

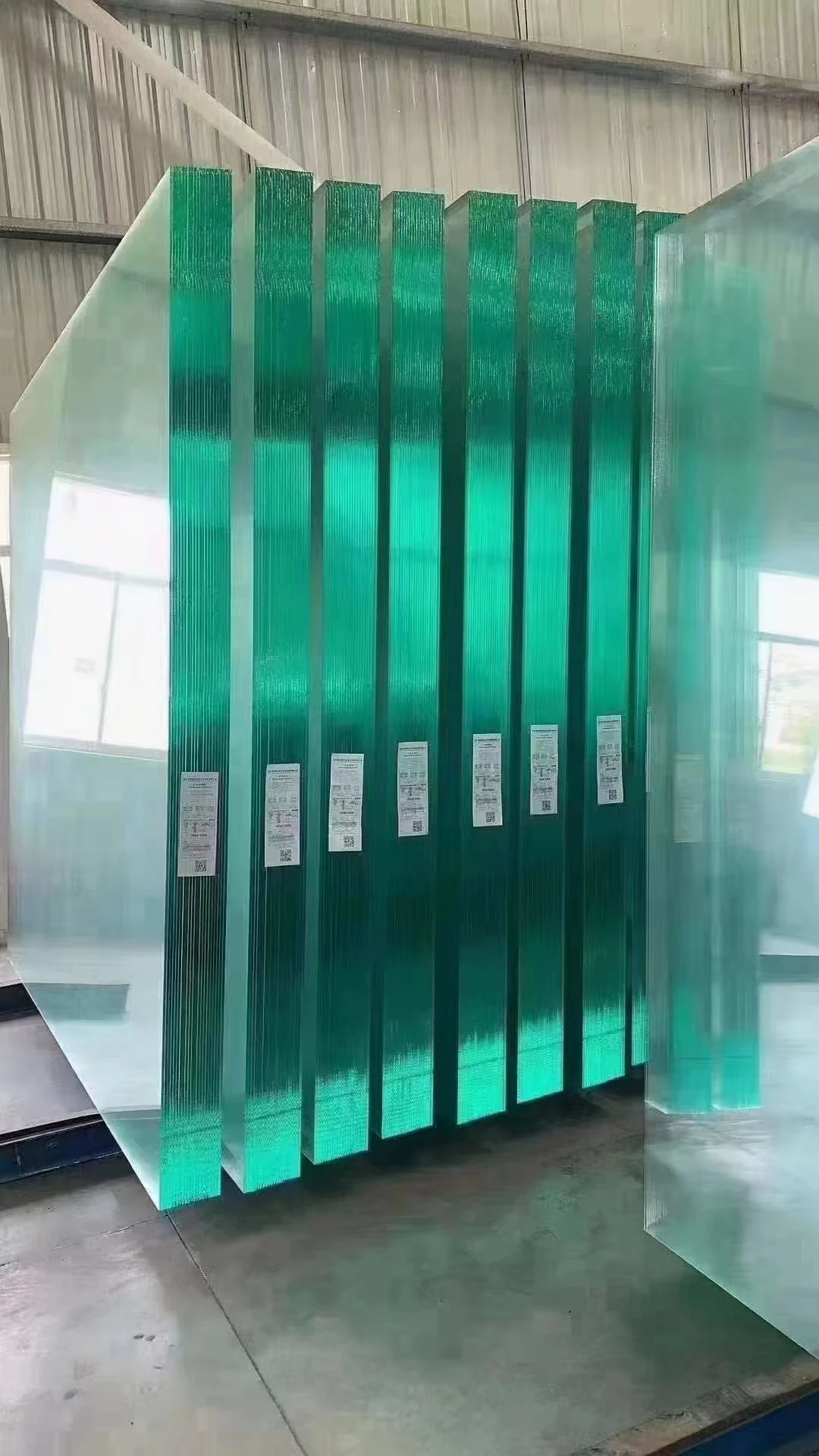

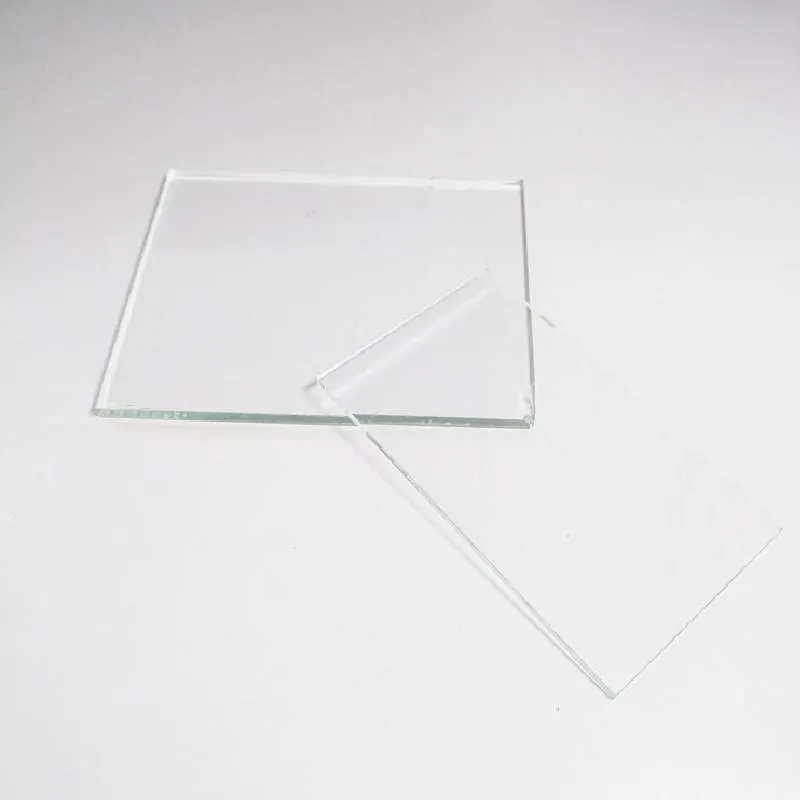

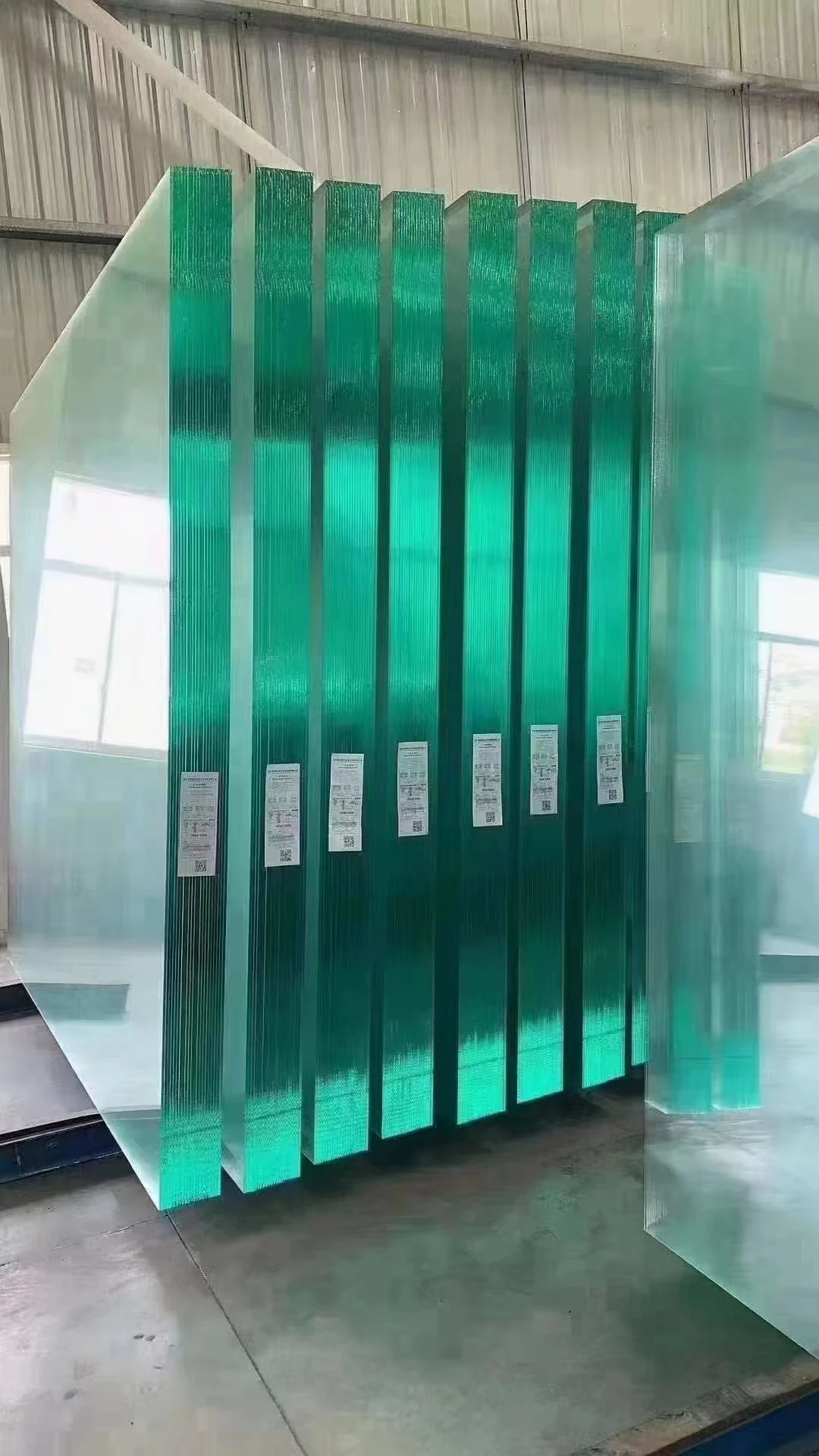

Float glass, also known as flat glass, is produced by floating molten glass on a bed of molten tin. This method, perfected since its introduction by Sir Alastair Pilkington in the 1950s, allows for the creation of uniform and smooth sheets, a standard that was previously unachievable. The expertise involved in this process is crucial. Manufacturers must maintain precise control over temperature and composition to ensure consistency and quality, which is why factories invest heavily in technology and skilled personnel.

A critical component of float glass manufacturing is the raw materials. Silica sand, calcium oxide, and sodium carbonate are combined in proportionate measures to create glass of distinct composition and strength. Expertise in sourcing and mixing these materials determines the final product quality. Understanding the subtle impact of each component allows manufacturers to customize glass for different applications, whether it be tempered glass for automotive use or energy-efficient low-emissivity glass for environmentally-conscious building projects.

In terms of experience, managing the float glass production line requires keen attention to detail and robustness in handling technical challenges. The molten glass must cool at a controlled rate to prevent imperfections. The process spans several phases, from forming and cooling to cutting and treating, necessitating vigilant oversight. Professionals in the field often collaborate with engineers and quality assurance teams to troubleshoot and perfect every step.

float glass manufacturing

Innovation continues to drive the float glass sector. Sustainable practices are becoming increasingly vital; thus, manufacturers are exploring ways to reduce emissions and energy consumption. Advances in recycling technologies and the use of alternative energies are gaining traction within the industry, reflecting a shift towards more eco-friendly manufacturing. This evolution portrays a commitment not only to high-quality products but also to global environmental standards.

Trustworthiness in float glass manufacturing centers around compliance with rigorous industry standards. Certifying bodies across various regions dictate stringent quality and safety protocols that manufacturers must adhere to. Customers rely on these standards to ensure that the glass will perform safely and effectively under expected conditions. That's why manufacturers must not only meet these requirements but also continuously innovate to surpass them, fostering trust among consumers and industry partners alike.

Additional developments include advancements in smart glass technologies. Manufacturers are leveraging expertise in electronics and material sciences to develop glass that can modulate light or heat, offering enhanced control over indoor environments. This is becoming particularly prominent in the architectural industry, where energy efficiency is increasingly prioritized.

In sum, float glass manufacturing is a field that encompasses a blend of traditional expertise and cutting-edge innovation. Each sheet of glass represents a meticulous manufacturing process backed by authoritative industry knowledge. As global demand for versatile and sustainable building materials grows, the industry remains poised to lead with trustworthiness and efficiency. This continual evolution defines the core of float glass manufacturing, making it an indispensable component of modern life.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu