Understanding Tempered Glass Composition and Benefits

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated to increase its strength compared to standard glass. This sophisticated manufacturing process involves heating the glass to a high temperature and then rapidly cooling it, which enhances its overall durability. One of the most commonly asked questions about tempered glass is about its composition. What materials are used to create this sturdy material, and what makes it ideal for various applications?

At its core, tempered glass is typically made from silica sand, soda ash, and limestone, much like standard glass. However, the key to its enhanced strength lies in the additional materials that are sometimes included in the production process. These may include alumina, which helps to improve thermal stability, and magnesium oxide, which increases the glass's resistance to thermal shock. The precise composition can vary based on the specific requirements of the application, ensuring that the glass meets the necessary mechanical and thermal performance metrics.

Understanding Tempered Glass Composition and Benefits

Once the glass has been shaped, the tempering process begins. It involves heating the glass sheets to temperatures between 600 to 700 degrees Celsius (approximately 1112 to 1292 degrees Fahrenheit). After reaching the required temperature, the glass is rapidly cooled using powerful jets of air. This quenching process creates a layer of compressive stress on the surface of the glass. As a result, tempered glass is designed to endure greater impacts and thermal fluctuations than its non-tempered counterparts.

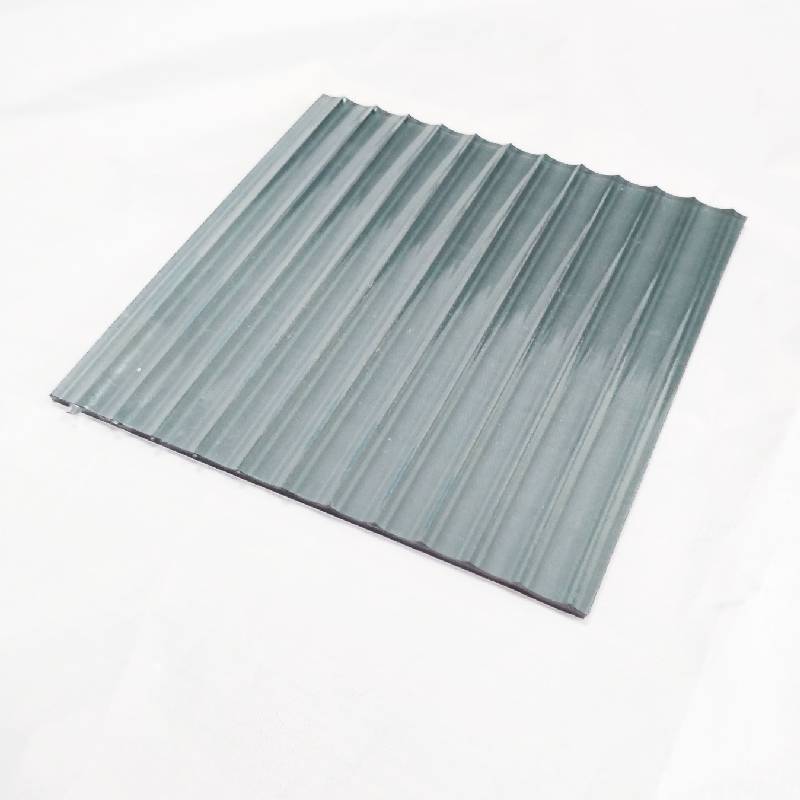

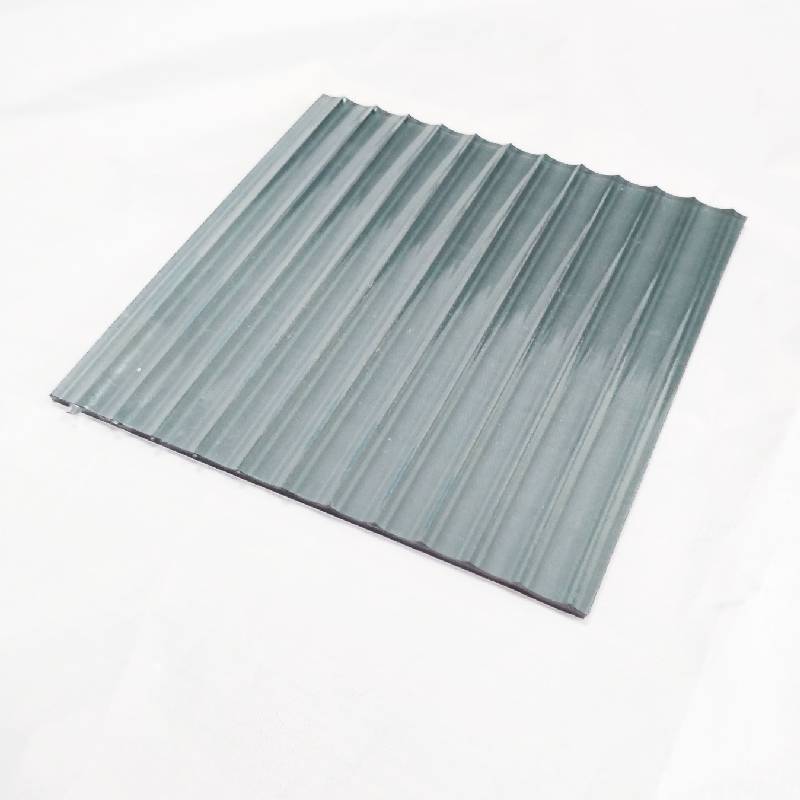

tempered glass made of

One of the most significant advantages of tempered glass is its safety feature. When shattered, tempered glass breaks into small, blunt pieces rather than sharp shards. This minimizes the risk of injury, making it a preferred choice for environments where safety is a top priority, such as in shower doors, glass doors, windows, and even in vehicles. Moreover, its thermal resistance makes it suitable for applications that involve high heat, such as in oven doors and glass table tops.

In addition to safety and thermal resistance, tempered glass is also aesthetically pleasing. It can be produced in various colors and finishes, allowing it to enhance the visual appeal of any space. Designers and architects favor tempered glass for its combination of safety, durability, and elegance.

Furthermore, as energy efficiency becomes increasingly important in modern construction, tempered glass can also contribute to better insulation. When used in double or triple-glazed setups, it helps improve the energy efficiency of buildings by reducing heating and cooling costs.

In conclusion, tempered glass is a remarkable material made primarily from silica, soda ash, and limestone, with enhancements from other additives for improved thermal and mechanical strength. Its unique manufacturing process not only increases safety and durability but also expands its applications across various industries. Whether in architecture, automotive design, or everyday applications, tempered glass is truly a versatile and essential material in today's world, providing both functionality and aesthetic appeal.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu