The Innovation of Float Glass A Modern Marvel

Float glass is a significant advancement in glass manufacturing, revolutionizing the way we think about and utilize this versatile material. Developed in the mid-20th century, float glass production has become the standard for creating flat glass, widely used in windows, doors, and various architectural applications. The uniqueness of the float glass process lies in its ability to produce sheets of glass that are exceptionally smooth and distortion-free, making it the preferred choice for both functional and aesthetic purposes.

The float glass manufacturing process was invented by Sir Alastair Pilkington in the 1950s and is characterized by a continuous production method that involves floating molten glass on a layer of molten tin. This unique technique allows the glass to achieve a uniform thickness and a flawless surface finish. As the glass cools and solidifies on the tin bath, it retains its flatness and clarity, attributes that are essential for numerous applications, particularly in the construction industry.

One of the most prominent benefits of float glass is its optical clarity. Unlike traditional glassmaking methods, which can result in varying thickness and surface imperfections, float glass offers a consistent and high-quality product. This clarity is crucial not only for residential and commercial buildings but also for the automotive industry, where visibility and safety are paramount. As a result, float glass has become the go-to material for car windows, windshields, and mirrors.

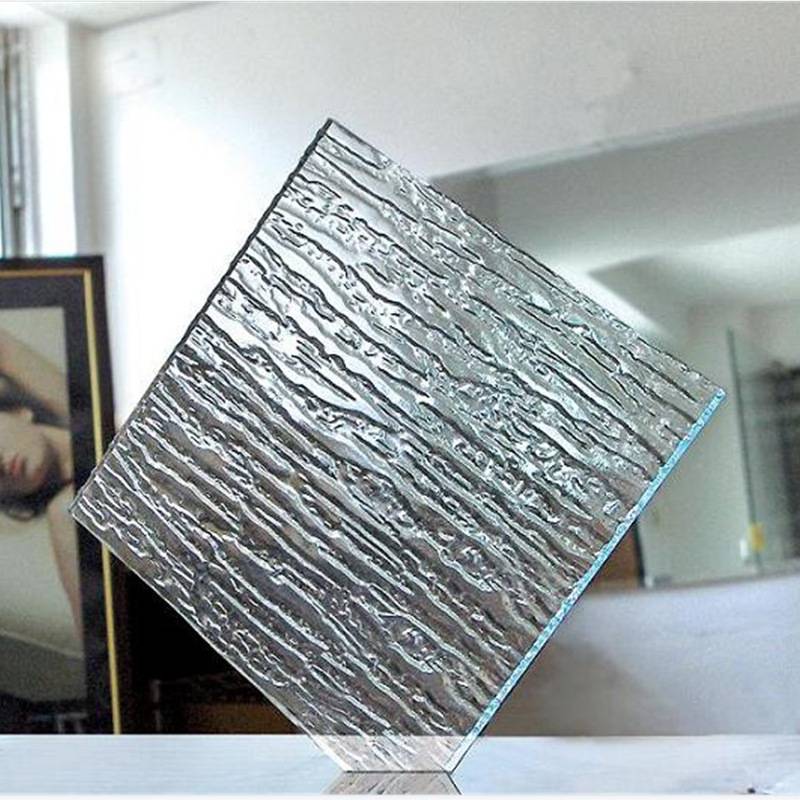

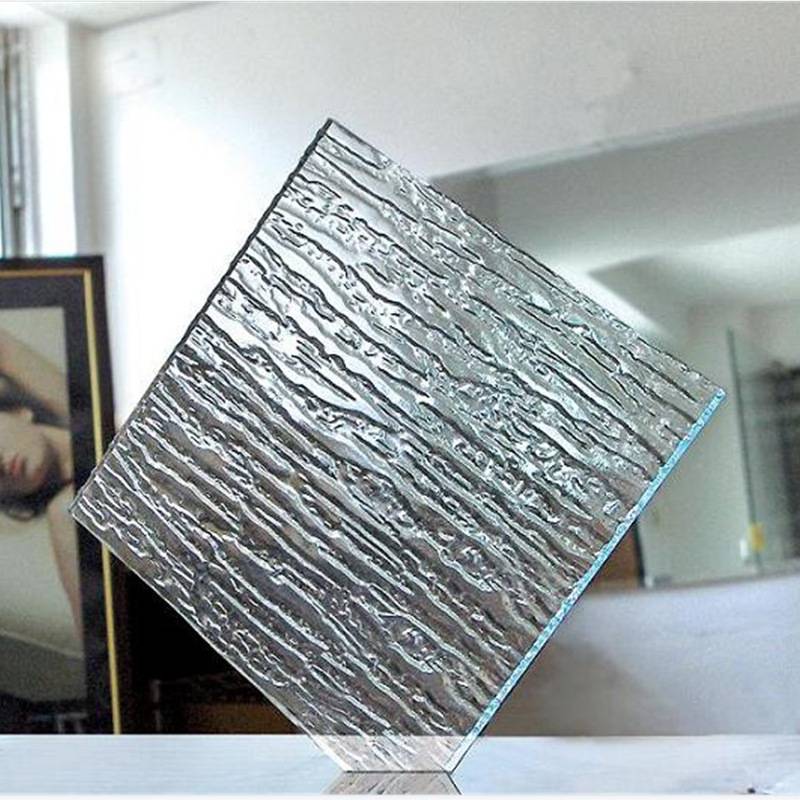

float glass

In addition to its aesthetic appeal, float glass is also an energy-efficient choice. The ability to produce large sheets with minimal waste has made float glass a sustainable option in the world of manufacturing. Various coating technologies can be applied to float glass to enhance its energy efficiency further. Low-emissivity (low-E) coatings can be applied to reduce heat transfer, while reflective coatings are useful in solar control applications. These innovations help to improve building energy performance, lower heating and cooling costs, and contribute to a more sustainable environment.

Furthermore, float glass is versatile and can be manipulated into different forms and features, making it suitable for a wide range of applications. In interior design, it is used for partitions, balustrades, and decorative elements, adding a sense of openness and light to spaces. Architects often incorporate float glass into their designs for facades, as it allows natural light to penetrate deep into interiors, creating harmonious and inviting environments.

The production of float glass has also adapted to modern demands and technological advancements. Automated manufacturing processes enhance efficiency and reduce labor costs, while continuous innovation in glass treatment processes ensures that products meet the highest safety and performance standards. As the market for float glass continues to grow, manufacturers are increasingly investing in research and development to explore new applications, including smart glass technologies that can change properties in response to environmental stimuli.

In conclusion, float glass is a remarkable innovation in the glass industry, providing a combination of aesthetic appeal, optical clarity, energy efficiency, and versatility. Its adoption in construction and various industrial sectors highlights the importance of advanced manufacturing processes and the continuous evolution of materials to meet modern demands. As the world progresses towards sustainable and innovative building practices, float glass will undoubtedly play a crucial role in shaping the environments we live and work in.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu