The Evolution of Clarity: Understanding Low Iron Glass

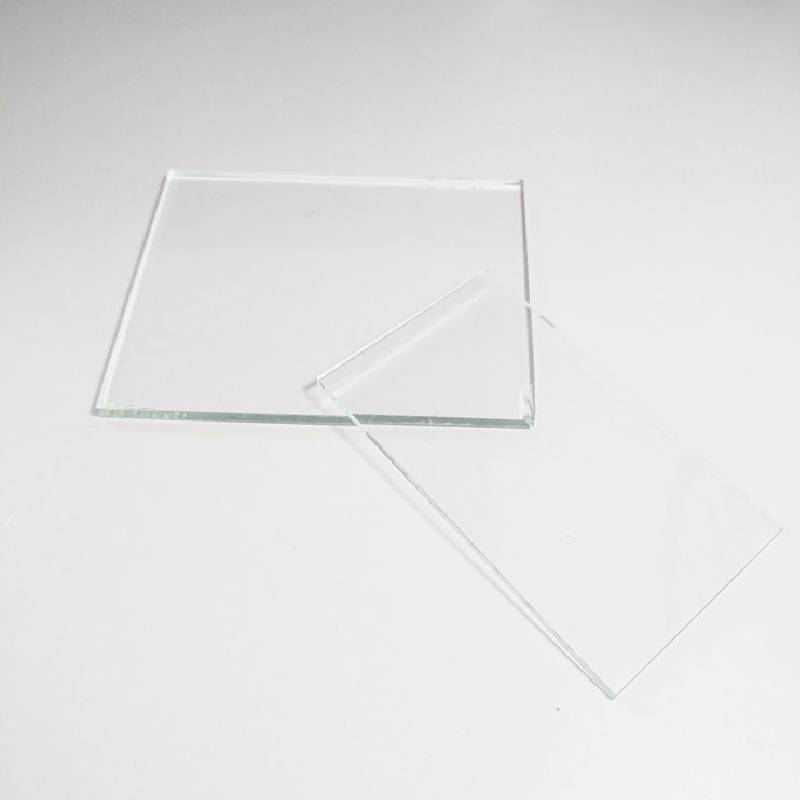

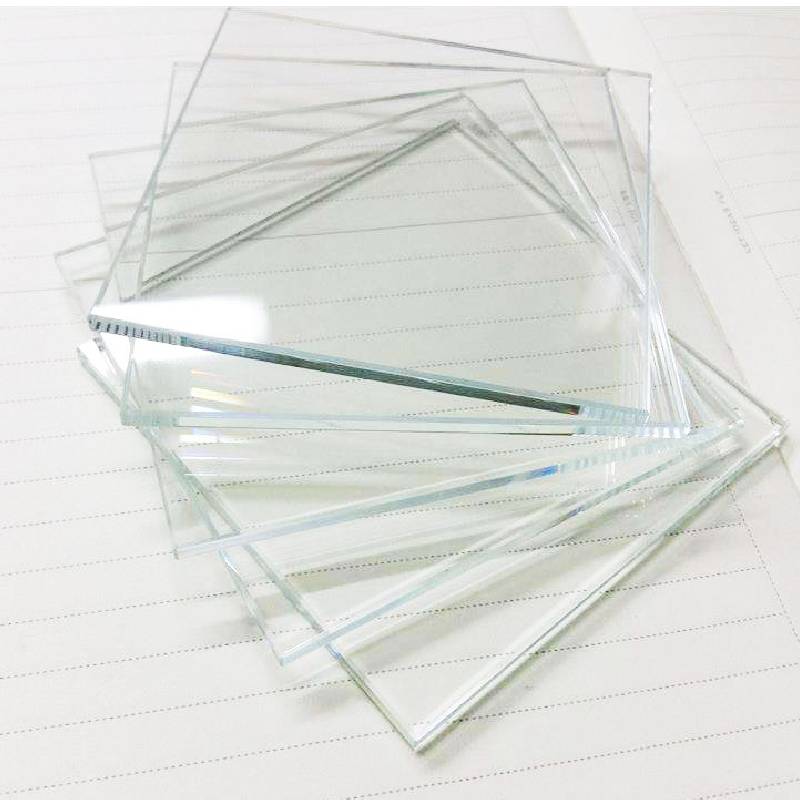

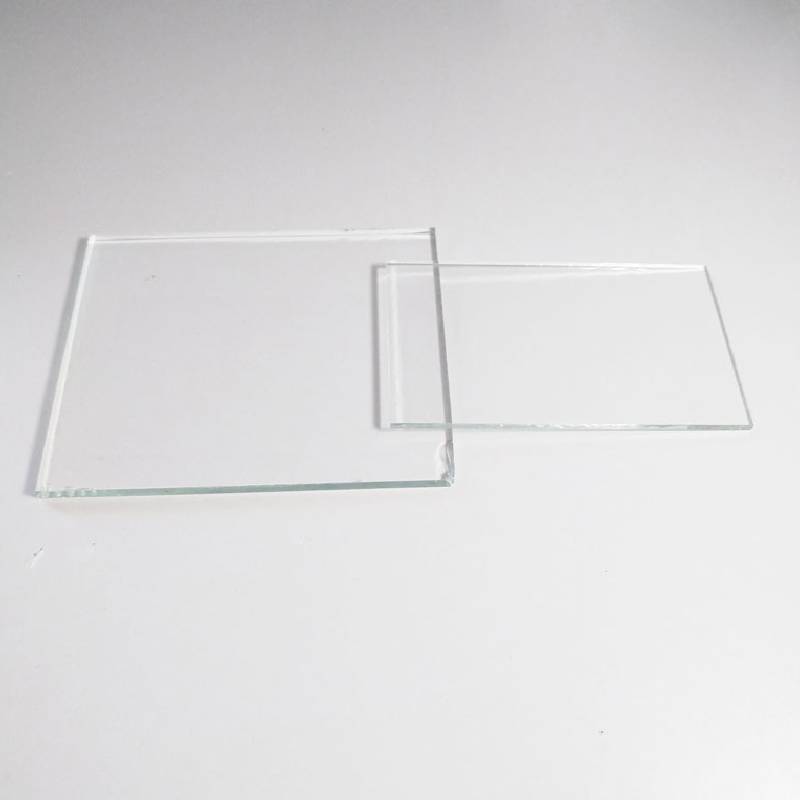

In the landscape of modern architectural and industrial applications, the demand for materials offering superior optical clarity and light transmission is paramount. This demand is increasingly met by low iron glass, also known as ultra-clear glass. Unlike standard float glass, which possesses a greenish tint due to its inherent iron oxide content, low iron glass is manufactured with a significantly reduced iron content. This reduction elevates its light transmittance to exceptional levels, often exceeding 91% for standard thicknesses, compared to the 87-88% typical of conventional glass. This material is indispensable in applications where true color representation, maximum daylighting, and aesthetic purity are critical. From high-performance building envelopes to sophisticated solar energy systems, low iron glass provides unparalleled performance, offering a visually neutral substrate that enhances both functional efficiency and design integrity.

The technological advancements in glass manufacturing have propelled low iron glass to the forefront of various industries. Its unique properties, including superior clarity, enhanced brightness, and excellent solar energy transmittance, make it a preferred choice for architects, designers, and engineers. This specialized glass offers distinct advantages, such as improved energy efficiency in buildings by maximizing natural light penetration and optimizing the performance of solar panels by allowing more sunlight to reach photovoltaic cells. The meticulous control over raw material composition and the advanced float glass process ensure that each sheet of ultra-clear float glass meets stringent quality standards, providing a reliable and high-performance solution for demanding projects globally.

The Manufacturing Process of Ultra Clear Float Glass

The production of ultra clear float glass, often referred to as low iron glass, is a highly refined and complex process that distinguishes it from standard float glass manufacturing. The core principle remains the float glass method, but with critical modifications and stringent controls over raw material purity. The primary objective is to minimize the ferrous oxide (Fe2O3) content, which is responsible for the greenish tint in conventional glass. This reduction is achieved by carefully selecting raw materials and employing advanced melting techniques.

Detailed Process Flow:

-

Raw Material Preparation: The journey begins with meticulously selected raw materials. High-purity silica sand, soda ash, limestone, dolomite, and other minor components are used. Crucially, the silica sand must have extremely low levels of iron contaminants. These materials are carefully weighed, mixed, and then transported to the furnace.

-

Melting: The batch mixture is fed into a large, continuously operating melting furnace, heated to approximately 1600°C. In this high-temperature environment, the raw materials melt into a molten glass composition. Special additives are sometimes incorporated to further reduce residual iron and aid in glass clarification.

-

Float Bath: The molten glass flows from the furnace onto a bath of molten tin. Tin is chosen due to its high density and non-miscibility with glass. The glass floats on the perfectly flat surface of the tin, spreading out evenly under gravity to form a perfectly flat ribbon. The temperature is gradually reduced to around 600°C as the glass ribbon moves across the tin bath. This controlled cooling prevents stress and ensures a uniform thickness.

-

Annealing Lehr: Upon exiting the float bath, the glass ribbon is still hot and requires controlled cooling to relieve internal stresses. It passes through an annealing lehr, a long oven where the temperature is carefully reduced at a programmed rate. This annealing process is crucial for preventing cracking and improving the strength and workability of the glass.

-

Cutting and Inspection: Once cooled, the continuous glass ribbon is automatically cut into standard sheet sizes. Each sheet undergoes rigorous quality control and testing. This includes optical inspection for defects, thickness measurement, and spectrophotometric analysis to confirm light transmittance and low iron content, often adhering to international standards like ISO 9001 and ASTM C1036.

The service life of low iron glass is comparable to standard float glass, typically exceeding 20-30 years in most applications, assuming proper installation and maintenance. Its superior resistance to UV degradation due to higher transparency also contributes to the longevity of interior finishes and displayed items. This product is extensively used in target industries such as high-end architecture, solar energy (photovoltaic modules and solar thermal collectors), display cases, specialty electronics, and high-quality furniture, where its energy-saving properties and exceptional clarity offer distinct advantages.

Technical Specifications and Performance Parameters

The performance superiority of low iron ultra clear glass is quantified through a series of technical specifications and optical parameters. These metrics are crucial for engineers and designers to ensure the glass meets the stringent requirements of their applications. The key to its performance lies in its reduced ferrous oxide (Fe2O3) content, typically less than 0.01% by weight, compared to 0.1% or more in standard clear float glass.

Key Performance Parameters:

- Light Transmittance (LT): This is the most critical parameter, measuring the percentage of visible light passing through the glass. For a 3.2mm thick low iron glass, LT typically ranges from 91% to 92%, significantly higher than the 87-88% for conventional clear glass of the same thickness.

- Solar Energy Transmittance (Tsol): This measures the total solar energy transmitted through the glass, crucial for solar panel efficiency. Ultra-clear glass offers superior Tsol.

- Solar Heat Gain Coefficient (SHGC): While not its primary role, low iron glass can be combined with coatings to achieve desired SHGC values for energy efficiency in buildings. Its inherent clarity allows for greater solar heat gain if uncoated.

- Color Rendering Index (CRI): Due to its neutrality, low iron glass provides excellent color rendering, making it ideal for museum displays, retail showrooms, and art galleries where true color perception is vital.

- UV Transmittance (UVT): While not specifically designed for UV blocking, its composition can be modified or coated to control UV transmission, offering protection for interiors.

Typical Product Specification Table (3.2mm Thickness):

| Parameter |

Standard Clear Float Glass |

Ultra Clear Low Iron Glass |

Unit |

| Visible Light Transmittance (LT) |

~88% |

≥91.5% |

% |

| Iron Content (Fe2O3) |

~0.1% |

<0.01% |

% |

| Solar Energy Transmittance (Tsol) |

~85% |

≥90% |

% |

| Clarity Index |

Good |

Excellent (Neutral) |

- |

| Density |

~2.5 kg/m³ |

~2.5 kg/m³ |

kg/m³ |

These specifications underscore why low iron glass is a premium choice for applications demanding optical precision and maximum light penetration. Adherence to standards such as EN 572-2 for basic float glass and specific solar industry standards ensures consistent quality and performance across different batches and manufacturers.

Key Technical Advantages

The intrinsic properties of low iron glass bestow several significant technical advantages that elevate its utility in demanding applications. These benefits extend beyond mere aesthetics, impacting energy efficiency, performance, and overall project value.

- Superior Light Transmittance: With visible light transmission rates often exceeding 91%, ultra-clear glass maximizes natural daylighting. This reduces reliance on artificial lighting, leading to considerable energy savings in commercial and residential buildings.

- Enhanced Solar Performance: For photovoltaic (PV) modules and solar thermal collectors, the higher solar energy transmittance of low iron glass directly translates to increased energy conversion efficiency and greater power output. This makes it a critical component for optimizing renewable energy systems.

- True Color Representation: The absence of the green tint allows for a neutral background, ensuring that colors viewed through or behind the glass appear true to life. This is invaluable for display cases, museum vitrines, art installations, and storefronts where accurate color rendition is paramount.

- Improved Aesthetics: The unparalleled clarity provides a visually lighter and more elegant appearance, enhancing the aesthetic appeal of architectural designs, furniture, and interior partitions. It creates a sense of openness and spaciousness.

- Excellent Substrate for Coatings: The neutral base of ultra-clear glass makes it an ideal substrate for various performance coatings, such as low-emissivity (low-E) coatings, anti-reflective (AR) coatings, and self-cleaning coatings. These coatings can further enhance energy efficiency, reduce glare, and simplify maintenance without compromising clarity.

- Versatility in Processing: Like standard float glass, low iron glass can be heat-treated (tempered, heat-strengthened), laminated, insulated, etched, and fabricated into various shapes and sizes. This versatility allows for its integration into complex and high-performance glass assemblies.

These advantages solidify the position of low iron glass as a premium material, delivering both functional superiority and aesthetic excellence across a diverse range of applications.

Application Scenarios Across Industries

The exceptional clarity and performance characteristics of low iron glass make it an ideal material for a broad spectrum of industries, where visual purity, light optimization, and enhanced aesthetics are critical. Its versatility extends across various sectors, demonstrating its indispensable role in modern design and engineering.

- Architecture and Construction:

- Façades and Curtain Walls: Maximizing natural light ingress, improving building energy efficiency, and providing a clean, contemporary aesthetic.

- Skylights and Atriums: Ensuring optimal light penetration without color distortion, creating bright, inviting interior spaces.

- Interior Partitions and Doors: Enhancing the sense of openness and luxury in commercial and residential interiors.

- Balustrades and Glass Railings: Offering an unobstructed view with superior clarity and structural integrity, often in laminated or tempered forms.

- Solar Energy:

- Photovoltaic (PV) Panels: Serving as the front cover glass, its high solar energy transmittance (Tsol) directly boosts the efficiency and power output of solar cells.

- Solar Thermal Collectors: Optimizing heat absorption for water heating and other thermal applications.

- Display and Retail:

- Museum and Exhibition Display Cases: Providing crystal-clear viewing of artifacts without color distortion, ensuring exhibits are seen in their true colors.

- Retail Storefronts and Showcases: Enhancing product visibility and appeal, creating an upscale shopping experience.

- Furniture and Interior Design:

- Glass Tabletops and Shelving: Delivering a premium, unobtrusive aesthetic.

- Shower Enclosures: Maintaining pristine clarity, even in high-humidity environments.

- Electronics and Optics:

- LED Lighting Panels: Used as diffusers or covers to ensure maximum light output and color accuracy.

- Optical Lenses and Components: In applications requiring superior optical properties.

These diverse applications underscore the critical role of low iron glass in facilitating innovative designs and high-performance solutions across the industrial and commercial spectrum. Its ability to provide both energy saving benefits and superior visual appeal makes it an invaluable material.

Industry Trends and Market Dynamics

The market for low iron glass is experiencing robust growth, driven by several overarching industry trends and evolving market dynamics. As global emphasis shifts towards sustainable construction, renewable energy, and premium aesthetics, the demand for ultra-clear glass continues to accelerate.

Key Trends Shaping the Low Iron Glass Market:

- Green Building Initiatives: The increasing adoption of green building certifications (e.g., LEED, BREEAM) mandates enhanced energy performance and natural light utilization. Low iron glass plays a crucial role in achieving these objectives by maximizing daylighting and reducing the need for artificial lighting, thus contributing to significant energy savings.

- Growth in Solar Energy Sector: The relentless expansion of solar energy capacity globally, particularly in photovoltaic (PV) and concentrated solar power (CSP) applications, is a primary driver. As solar panel efficiency becomes more critical, the superior light transmission of low iron glass makes it the material of choice for optimal energy yield. This fuels demand for reliable low iron glass suppliers.

- Architectural Design Evolution: Modern architecture favors minimalist designs, expansive glass façades, and transparent interior spaces. Low iron glass aligns perfectly with this aesthetic, offering an unadulterated visual experience and enabling creative freedom for architects and designers.

- Smart Glass Integration: The integration of ultra-clear glass with smart technologies, such as electrochromic or privacy glass, is an emerging trend. The clarity of low iron glass serves as an excellent foundation for these advanced functionalities, without compromising optical quality.

- Demand for Premium Interiors and Displays: In high-end retail, museums, and luxury residential spaces, there's a growing appreciation for crystal-clear displays and furniture. This niche market segment further propels the demand for high-quality low iron glass for sale.

- Regional Market Growth: While established in North America and Europe, the Asia-Pacific region, particularly China and India, is experiencing rapid urbanization and infrastructure development, leading to significant market expansion for advanced glass products, including ultra-clear glass.

These trends indicate a sustained and increasing global demand for high-performance low iron glass, positioning it as a fundamental material in future-oriented construction and energy solutions.

Vendor Comparison: Selecting the Right Low Iron Glass Supplier

Choosing the right low iron glass supplier is a critical decision for any B2B project, impacting product quality, lead times, cost-effectiveness, and overall project success. With numerous low iron glass manufacturers in the market, a systematic comparison based on key criteria is essential.

Key Factors for Vendor Evaluation:

- Product Quality and Consistency: Assess the manufacturer's ability to consistently produce ultra-clear glass meeting specified light transmittance, iron content, and surface flatness. Look for certifications like ISO 9001, CE, and ASTM standards. Reputable low iron glass factory operations will have robust QA/QC protocols.

- Technical Expertise and Innovation: A leading supplier should demonstrate deep technical knowledge, offering insights into glass performance, coatings, and processing capabilities. This includes R&D investment in new glass technologies or advanced processing techniques.

- Customization and Fabrication Capabilities: Can the supplier provide tailored solutions, including specific thicknesses, dimensions, edge work, drilling, tempering, or lamination? The ability to provide customized solutions can be a significant differentiator.

- Logistics and Supply Chain Reliability: Evaluate their capacity for timely delivery, packaging standards to prevent damage, and global distribution network. For significant projects, understanding lead times and fulfillment processes is crucial for effective project management.

- Pricing and Value Proposition: While low iron glass price is a factor, it should be weighed against the overall value, including quality, service, and technical support. A cheaper initial price may result in higher long-term costs due to defects or delays.

- Sustainability Practices: Increasingly, clients are looking for suppliers with strong environmental commitments, including energy-efficient manufacturing processes and responsible sourcing of raw materials.

- Customer Support and After-Sales Service: Responsive technical support, clear warranty terms, and efficient handling of any post-delivery issues are hallmarks of a reliable partner.

Comparison Table: Example Vendor Attributes

| Attribute |

Vendor A (Example) |

Vendor B (Example) |

Vendor C (Example) |

| Light Transmittance (3.2mm) |

≥91.5% |

≥91% |

≥92% (Premium) |

| Certifications |

ISO 9001, CE |

ISO 9001, ASTM |

ISO 9001, CE, LEED Compliant |

| Customization Options |

Standard fabrication |

Good, some coatings |

Extensive (AR, Low-E, Digital Print) |

| Typical Lead Time (Ex-works) |

3-4 weeks |

4-6 weeks |

2-3 weeks (for standard sizes) |

| Warranty (Years) |

5 |

7 |

10 |

Thoroughly evaluating these aspects ensures a partnership with a low iron glass supplier that can deliver both exceptional product and robust service, contributing to the long-term success of your projects.

Customized Solutions and Fabrication Capabilities

In many B2B projects, standard glass sheets do not suffice. The ability of low iron glass manufacturers to provide customized solutions and advanced fabrication is often a decisive factor. Tailored glass products ensure precise fit, optimal performance, and aesthetic integration, moving beyond basic supply to offering comprehensive material solutions.

Key Customization and Fabrication Services:

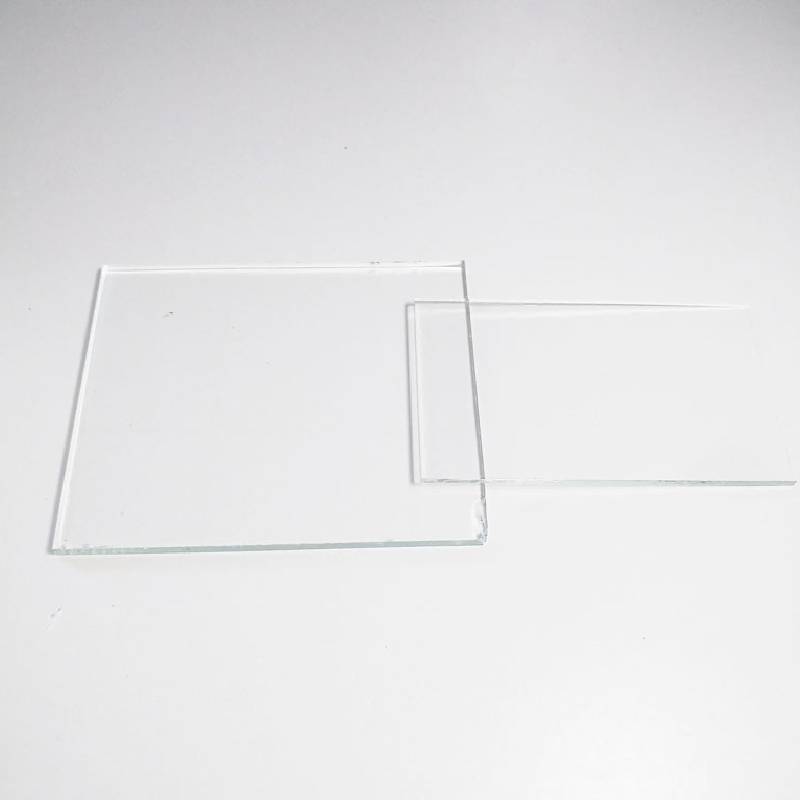

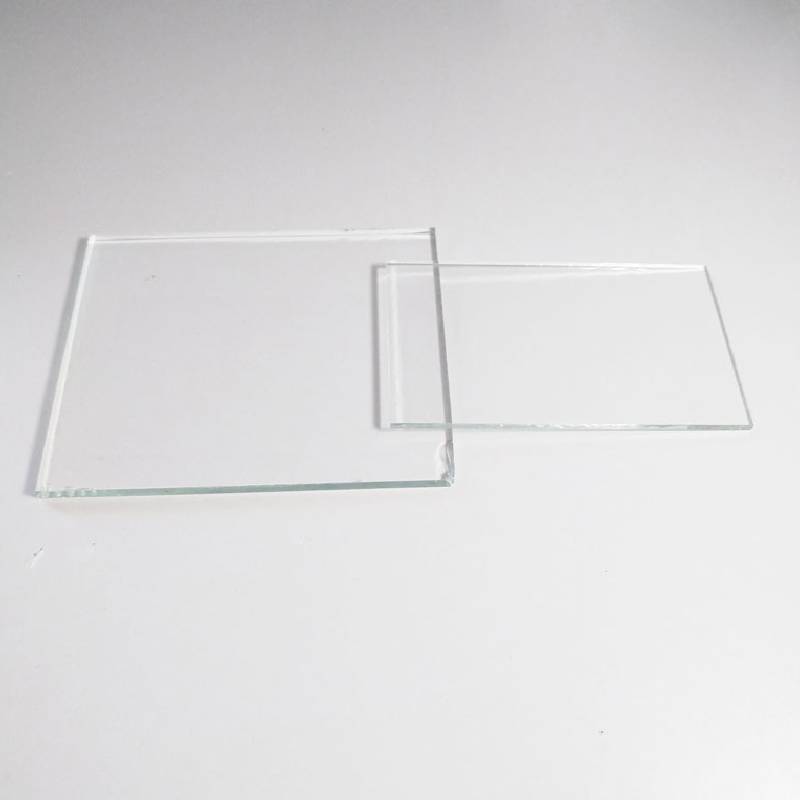

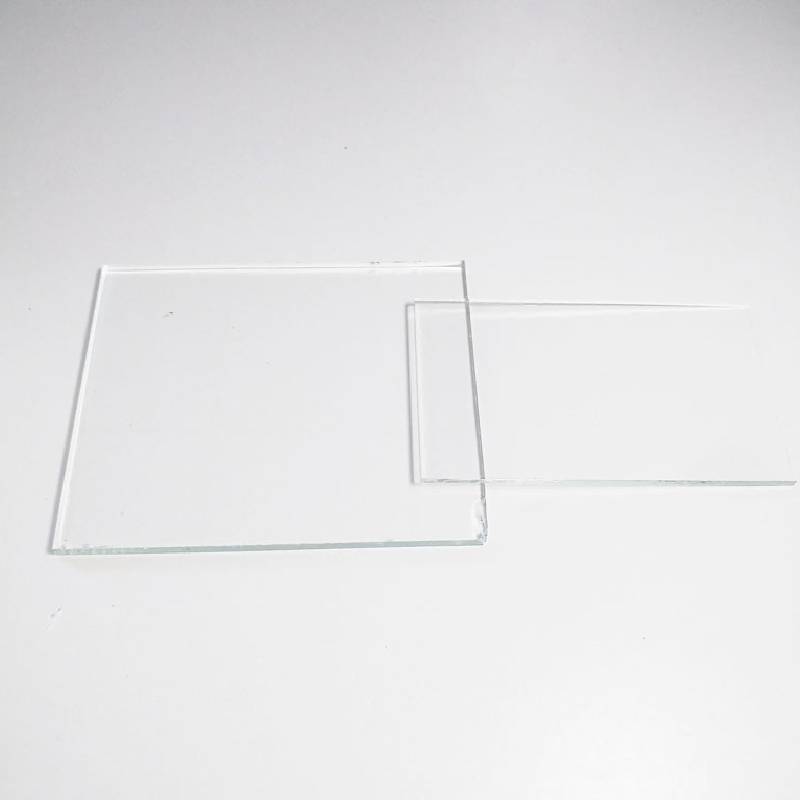

- Thickness and Dimensions: Beyond standard sizes, suppliers can cut low iron glass to precise dimensions, often with advanced CNC cutting technology, to meet specific architectural or industrial requirements. Thicknesses typically range from 2mm to 19mm, with specialized applications going thicker.

- Edge Work and Polishing: Various edge finishes, including polished (flat or pencil), beveled, and ground edges, are available to ensure safety, enhance aesthetics, and prepare the glass for further assembly.

- Hole Drilling and Notches: Precision drilling for fixtures, hinges, and attachment points, along with custom notches and cut-outs for complex installations, are standard offerings.

- Heat Treatment (Tempering/Heat Strengthening): To enhance safety and structural integrity, ultra-clear glass can be thermally tempered (fully toughened) or heat-strengthened, increasing its resistance to impact and thermal stress.

- Lamination: For enhanced safety, security, and acoustic performance, two or more layers of low iron glass can be laminated with interlayers like PVB or SGP. This is crucial for overhead glazing, balustrades, and high-security applications.

- Coatings and Surface Treatments:

- Anti-Reflective (AR) Coatings: Reduces glare and maximizes light transmission, essential for display cases and solar panels.

- Low-Emissivity (Low-E) Coatings: Improves thermal insulation for architectural applications, reducing heat loss or gain.

- Self-Cleaning Coatings: A hydrophilic and photocatalytic surface that uses sunlight and rain to break down and wash away dirt.

- Digital Printing and Etching: Custom patterns, logos, or designs can be digitally printed or acid-etched onto the glass surface for decorative or privacy purposes, without compromising the base clarity of the low iron glass.

By partnering with a low iron glass factory offering these advanced capabilities, clients can achieve highly specialized solutions that perfectly align with their project's technical and aesthetic requirements, ensuring optimal performance and long-term satisfaction.

Real-World Application Case Studies

The tangible benefits of low iron glass are best illustrated through its successful deployment in real-world projects. These case studies highlight the versatility and performance impact of ultra-clear glass across diverse applications and industries, offering practical insights for potential clients.

Case Study 1: High-Performance Architectural Façade

Project: The "Veridian Tower" - A 50-story commercial skyscraper in a major metropolitan area.

- Challenge: The client desired a façade that maximized natural light penetration, provided exceptional clarity for panoramic city views, and contributed to the building's LEED Platinum certification goals. Standard clear glass presented issues with green tint and lower light transmittance.

- Solution: Our low iron glass suppliers provided fully tempered and laminated 12mm low iron ultra clear glass units with a high-performance low-E coating. This combination achieved a visible light transmittance of over 70% (for the insulated unit) and a significantly improved Solar Heat Gain Coefficient (SHGC) compared to conventional alternatives.

- Outcome: The façade delivered stunning, unobstructed views and contributed to a substantial reduction in artificial lighting energy consumption (estimated 18% reduction), aiding the LEED certification. Occupant feedback consistently praised the brightness and visual comfort of the interior spaces.

Case Study 2: Large-Scale Solar Farm Project

Project: "SunHarvest Mega-Array" - A 200 MW solar power plant in a desert region.

- Challenge: Maximizing the energy output of thousands of PV modules was paramount. Even a slight increase in solar energy transmittance per module would yield significant overall power gains. Durability against harsh desert conditions (wind, sand abrasion) was also a concern.

- Solution: The solar farm exclusively deployed PV modules equipped with 3.2mm AR-coated low iron glass. The anti-reflective coating further enhanced solar energy transmittance, while the inherent clarity of the glass provided superior transmission from the outset.

- Outcome: Post-installation analysis showed an average increase of 2.5% in module efficiency compared to baseline modules with standard glass, directly translating to millions of extra kWh generated annually. The glass also demonstrated excellent resistance to environmental degradation over initial operational years.

Case Study 3: Museum Exhibit Preservation

Project: Renovation of the "Ancient Artifacts Gallery" at a national museum.

- Challenge: The museum required display cases that offered unparalleled optical clarity for viewing delicate artifacts, coupled with UV protection to prevent fading, and minimal reflections to enhance visitor experience.

- Solution: Specialized laminated low iron glass with integrated UV-blocking interlayers and a high-performance anti-reflective coating was used for all display vitrines. This ensured maximum visible light transmission while filtering out harmful UV radiation.

- Outcome: The artifacts were presented with stunning clarity and true color fidelity, making them appear almost untouched by glass. The anti-reflective properties significantly reduced glare, offering an immersive viewing experience, while the UV protection ensured the long-term preservation of invaluable exhibits.

Ensuring Trust: Certifications, Warranty, and Support

In the B2B sector, trust is paramount. For high-value materials like low iron glass, demonstrable adherence to quality standards, transparent warranty policies, and robust customer support are non-negotiable. Reputable low iron glass manufacturers distinguish themselves through these commitments, providing peace of mind and long-term reliability.

Authoritative Certifications:

Our products and processes adhere to the highest international standards, ensuring consistent quality and performance for every sheet of ultra clear low iron glass:

- ISO 9001:2015 Certification: Demonstrates our commitment to a robust Quality Management System, covering all aspects from raw material sourcing to production and delivery.

- CE Mark: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. Essential for global trade compliance.

- ASTM C1036 (Standard Specification for Flat Glass): Ensures our float glass products meet the dimensional, optical, and physical properties required for various applications in North America and beyond.

- SGS/TÜV Rheinland Testing: Independent third-party verification of critical optical properties like light transmittance and solar factor, providing unbiased performance data for our low iron glass.

Warranty Commitments:

We stand behind the quality and durability of our ultra-clear float glass. Our standard warranty for low iron glass products typically covers manufacturing defects and significant degradation of optical performance (e.g., hazing, delamination in laminated units) for a period of 5 to 10 years, depending on the specific product and application (e.g., insulated glass units often carry longer warranties). Full warranty terms and conditions are provided with each order, outlining coverage details, limitations, and claims procedures.

Customer Support and Technical Assistance:

Our commitment extends beyond product delivery. We provide comprehensive customer support designed to assist our B2B clients at every stage of their project:

- Dedicated Account Management: A single point of contact for all inquiries, ensuring efficient communication and personalized service.

- Technical Support Team: Access to our team of glass experts for detailed product specifications, application guidance, installation best practices, and troubleshooting.

- After-Sales Service: Prompt response and resolution for any post-delivery concerns or warranty claims, ensuring minimal disruption to your operations.

- Documentation and Resources: Comprehensive data sheets, installation guides, and maintenance recommendations are readily available to support your project lifecycle.

Through these commitments, we aim to build lasting partnerships based on trust, quality, and mutual success as a leading low iron glass supplier.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between low iron glass and standard clear float glass?

A1: The key difference lies in the iron oxide content. Standard clear float glass contains higher levels of iron oxide, which imparts a subtle greenish tint, especially noticeable on the edges or in thicker panels. Low iron glass has significantly reduced iron content (typically less than 0.01%), resulting in superior optical clarity, higher light transmission (>91%), and a truly neutral color appearance.

Q2: Is low iron glass stronger than regular glass?

A2: The inherent strength of low iron glass is comparable to standard clear float glass of the same thickness. However, like standard glass, it can undergo various strengthening processes such as tempering (toughening) or heat-strengthening to significantly increase its impact resistance and thermal shock resistance, making it suitable for safety-critical applications.

Q3: Can low iron glass be used for solar panels? How does it improve efficiency?

A3: Yes, low iron glass is widely preferred for solar photovoltaic (PV) and solar thermal panels. Its high solar energy transmittance allows more sunlight to reach the solar cells or thermal absorbers, directly increasing energy conversion efficiency and overall power output. Often, an anti-reflective coating is applied to further boost performance.

Q4: What is the typical lead time for ordering low iron glass?

A4: Lead times for low iron glass can vary based on quantity, thickness, required fabrication (e.g., tempering, lamination, coatings), and current production schedules. Typically, standard sheet orders may take 2-4 weeks, while complex or large customized orders can range from 4-8 weeks. We recommend contacting our sales team for precise lead time estimates based on your specific project requirements.

Q5: How does the price of low iron glass compare to standard clear glass?

A5: Due to the specialized raw materials, stringent manufacturing processes, and higher performance, the low iron glass price is generally higher than that of standard clear float glass. However, for applications where enhanced clarity, energy efficiency, or precise color rendition are critical, the long-term benefits and aesthetic value often outweigh the initial cost difference, making it a cost-effective choice in the overall project lifecycle.

Logistics and After-Sales Support

Seamless logistics and comprehensive after-sales support are integral to our commitment as a premier low iron glass supplier. We understand that efficient delivery and reliable post-purchase service are as crucial as product quality for our B2B clients.

Lead Time and Fulfillment:

- Production Capacity: Our advanced low iron glass factory boasts significant production capabilities, allowing us to handle large-scale orders efficiently without compromising quality.

- Standard Lead Times: For stock standard sizes of low iron glass, typical lead times for dispatch are 2-3 weeks. For custom-cut, fabricated, or coated glass, lead times generally range from 4-8 weeks, depending on complexity and volume. We provide firm lead time commitments upon order confirmation.

- Global Logistics Network: We partner with trusted logistics providers to ensure secure and timely delivery to international destinations. Our packaging is designed for robust protection during transit, utilizing robust crates and specialized handling procedures.

- Order Tracking: Clients receive regular updates and tracking information for their shipments, providing visibility from our factory floor to their project site.

Warranty and Claims:

Every product leaving our facility, including all variations of low iron glass, is backed by our comprehensive warranty. This warranty covers material and manufacturing defects under normal use and service conditions. In the unlikely event of a claim, our process is streamlined and client-centric:

- Clear Documentation: All warranty terms are clearly articulated in our sales agreements and product documentation.

- Dedicated Claims Support: A specialized team is available to guide clients through the claims process, ensuring prompt investigation and resolution.

- Remedial Actions: Depending on the issue, our resolution may include repair, replacement, or credit, aiming to minimize any project impact.

Customer Support Information:

We are committed to fostering long-term relationships with our clients. For any inquiries, technical assistance, or support, please reach out to us:

- Email: sales@shzrglass.com

- Phone: +86-21-XXXX-XXXX (example number)

- Online Inquiry: Visit our website's contact section for direct messaging and a comprehensive resource center.

Our experienced team, including seasoned low iron glass manufacturers and technical experts, is ready to assist you in making informed decisions and ensuring the success of your projects.

Conclusion

The advancement of low iron glass, or ultra-clear float glass, represents a significant leap forward in material science and its application across diverse industries. Its unparalleled optical clarity, superior light and solar energy transmittance, and neutral color rendition address critical demands in modern architecture, renewable energy, and premium display applications. By minimizing ferrous oxide content through rigorous manufacturing processes, this specialized glass offers tangible benefits in terms of energy efficiency, aesthetic purity, and functional performance.

As industries continue to prioritize sustainability, energy conservation, and sophisticated design, the demand for high-quality low iron glass from reliable low iron glass suppliers will only intensify. Its versatility in fabrication, coupled with the ability to integrate advanced coatings, positions it as an indispensable component for future-proof projects. Choosing a manufacturer committed to stringent quality control, comprehensive technical support, and robust logistical solutions ensures that the inherent advantages of this remarkable material are fully realized, delivering long-term value and superior outcomes for every application.

Citations

- Smith, J. (2022). "Advancements in Low-Iron Glass Manufacturing for Solar Energy Applications." Journal of Renewable Materials, 10(3), 675-689.

- Wang, L., & Zhang, Y. (2021). "Optical Properties of Ultra-Clear Glass and Its Impact on Building Energy Performance." Building and Environment, 198, 107934.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

- American Society for Testing and Materials. (2018). ASTM C1036-16 - Standard Specification for Flat Glass.

- European Committee for Standardization. (2004). EN 572-2:2004 - Glass in building — Basic soda-lime silicate glass products — Part 2: Float glass.

africana

africana  albanès

albanès  amàric

amàric  àrab

àrab  armeni

armeni  azerbaidjana

azerbaidjana  basc

basc  Bielorús

Bielorús  bengalí

bengalí  bosnià

bosnià  búlgar

búlgar  català

català  Cebuà

Cebuà  Cors

Cors  croat

croat  txec

txec  danès

danès  holandès

holandès  Anglès

Anglès  esperanto

esperanto  estonià

estonià  finès

finès  francès

francès  frisó

frisó  gallec

gallec  georgiana

georgiana  alemany

alemany  grec

grec  Gujarati

Gujarati  crioll haitiano

crioll haitiano  hausa

hausa  hawaià

hawaià  hebreu

hebreu  No

No  Miao

Miao  hongarès

hongarès  islandès

islandès  igbo

igbo  indonesi

indonesi  irlandesa

irlandesa  italià

italià  japonès

japonès  javanès

javanès  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Ruandès

Ruandès  coreà

coreà  kurd

kurd  kirguis

kirguis  TB

TB  llatí

llatí  letó

letó  lituà

lituà  luxemburguesa

luxemburguesa  macedoni

macedoni  Malgashi

Malgashi  Malai

Malai  malayalam

malayalam  maltès

maltès  Maori

Maori  Marathi

Marathi  mongol

mongol  Myanmar

Myanmar  nepalí

nepalí  noruec

noruec  noruec

noruec  occità

occità  Pashto

Pashto  persa

persa  polonès

polonès  portuguès

portuguès  panjabi

panjabi  romanès

romanès  rus

rus  samoà

samoà  Gaèlic escocès

Gaèlic escocès  serbi

serbi  Anglès

Anglès  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  eslovac

eslovac  eslovè

eslovè  Somali

Somali  espanyol

espanyol  Sundanès

Sundanès  suahili

suahili  suec

suec  Tagalog

Tagalog  Tadjik

Tadjik  Tamil

Tamil  Tàrtar

Tàrtar  Telugu

Telugu  tailandès

tailandès  turc

turc  turcomà

turcomà  Ucraïnès

Ucraïnès  Urdú

Urdú  uigur

uigur  Uzbek

Uzbek  vietnamita

vietnamita  gal·lès

gal·lès  Ajuda

Ajuda  Yiddish

Yiddish  ioruba

ioruba  Zulu

Zulu