Understanding the Sheet Glass Process

The sheet glass process is a fascinating and complex method of manufacturing glass sheets, used widely in various industries, including construction, automotive, and electronics. The process involves several stages that transform raw materials into flat glass sheets of varying thicknesses, sizes, and qualities. This article will explore the key steps involved in the sheet glass manufacturing process and the technologies that drive it.

1. Raw Material Selection

The primary raw materials for glass production include silica sand, soda ash, and limestone. Silica sand is the main component, making up about 70-75% of the glass formula, providing the basic structure. Soda ash acts as a flux, lowering the melting temperature of the silica, while limestone contributes to the chemical durability of the final product. Additional materials like alumina and ferrous oxide may be added to enhance specific properties or produce colored glass.

2. Melting

Once the raw materials are selected and mixed in appropriate proportions, they undergo a melting process. The mixture is fed into a furnace heated to incredibly high temperatures, typically around 1,700°C (3,092°F). At these temperatures, the raw materials melt and fuse together to form molten glass. Modern furnaces can be either electric or gas-fired, with advancements in technology allowing for improved energy efficiency and reduced emissions.

3. Forming

After the glass is melted, the molten material needs to be formed into flat sheets. There are several methods of doing this, but the most common is the float glass process. In this method, the molten glass is poured onto a bath of molten tin. Due to the lower density of glass compared to tin, the glass floats on the tin surface, creating a smooth and flat sheet. The glass is allowed to cool and solidify as it moves through a controlled cooling chamber.

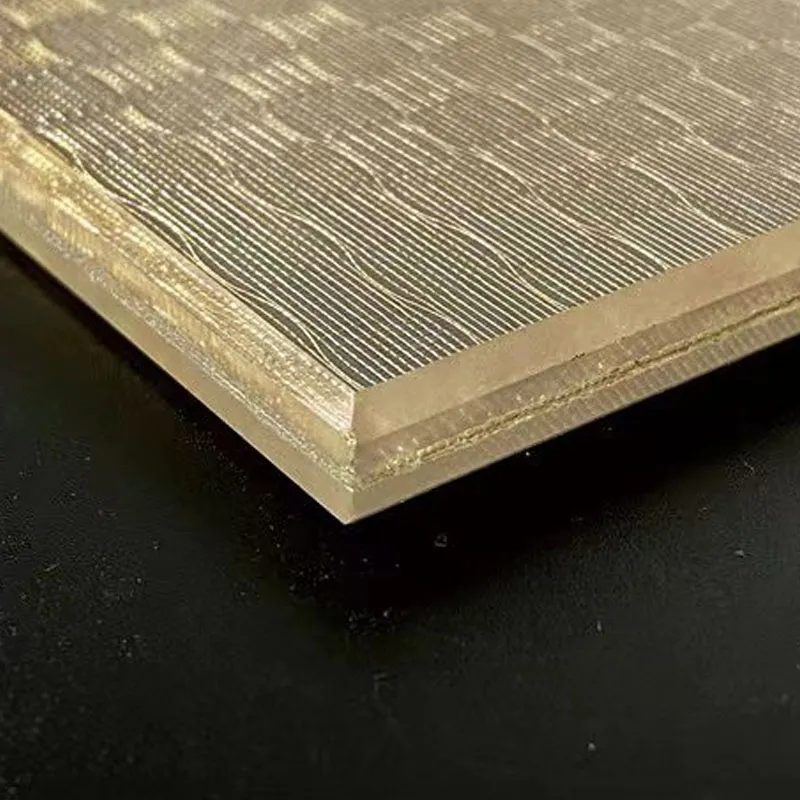

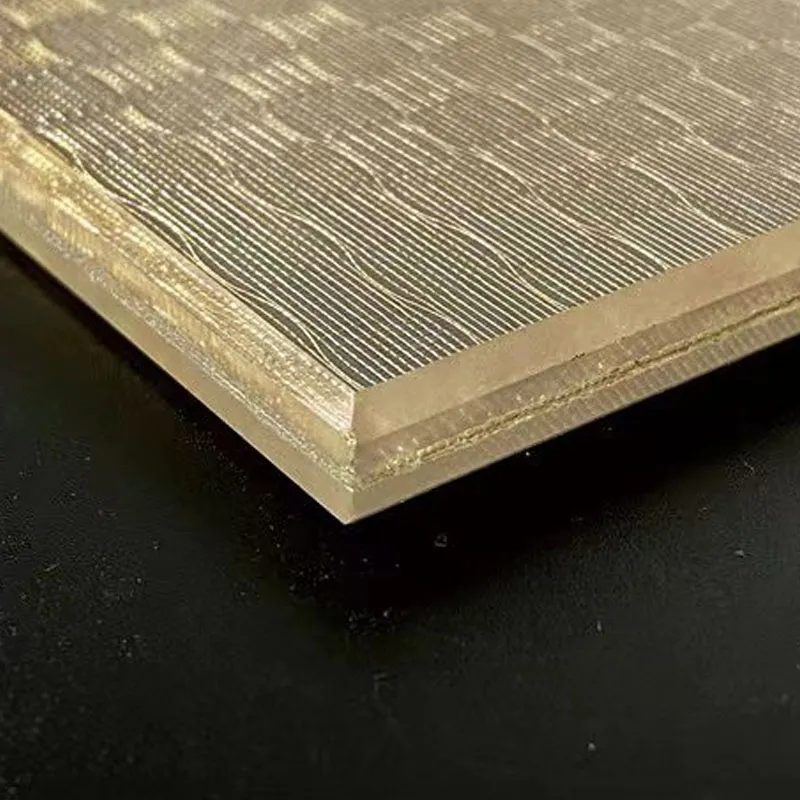

sheet glass process

4. Annealing

Once the glass sheets are formed, they undergo an annealing process, which involves carefully controlled cooling. This step is crucial as it relieves internal stresses that may have developed during the forming process. The glass is slowly cooled in an annealing lehr, ensuring uniform temperature distribution. This step helps improve the mechanical properties and dimensional stability of the glass sheets.

5. Cutting and Finishing

After annealing, the large sheets of glass are cut into smaller sizes based on customer requirements. Advanced cutting technologies, including water jet and laser cutting, are used to achieve precise dimensions. The edges of the glass sheets may be polished or treated to enhance safety and aesthetic appeal. Additional processes, such as laminating, tempering, or coating, may also be applied to add specific functionalities like increased strength or UV protection.

6. Quality Control

Quality control is an essential aspect of the sheet glass process. Samples from each batch are tested for clarity, thickness, optical properties, and surface defects. Advanced inspection techniques, such as automated vision systems, are employed to ensure that the final product meets industry standards and customer specifications. Any defects are identified and addressed before the glass proceeds to the market.

Conclusion

The sheet glass process is a highly technical endeavor that combines traditional craftsmanship with advanced manufacturing technologies. Understanding the intricacies of this process not only highlights its importance in our everyday lives but also underscores the need for innovation and sustainability in its production methods. As industries continue to evolve, the demand for high-quality glass products will persist, pushing the boundaries of what can be achieved through the sheet glass process.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu