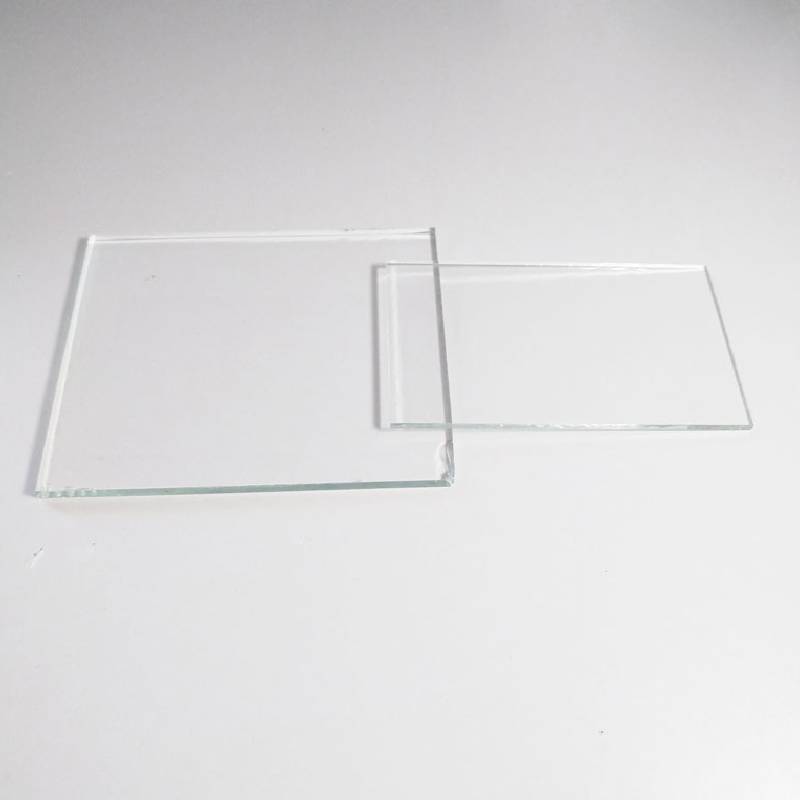

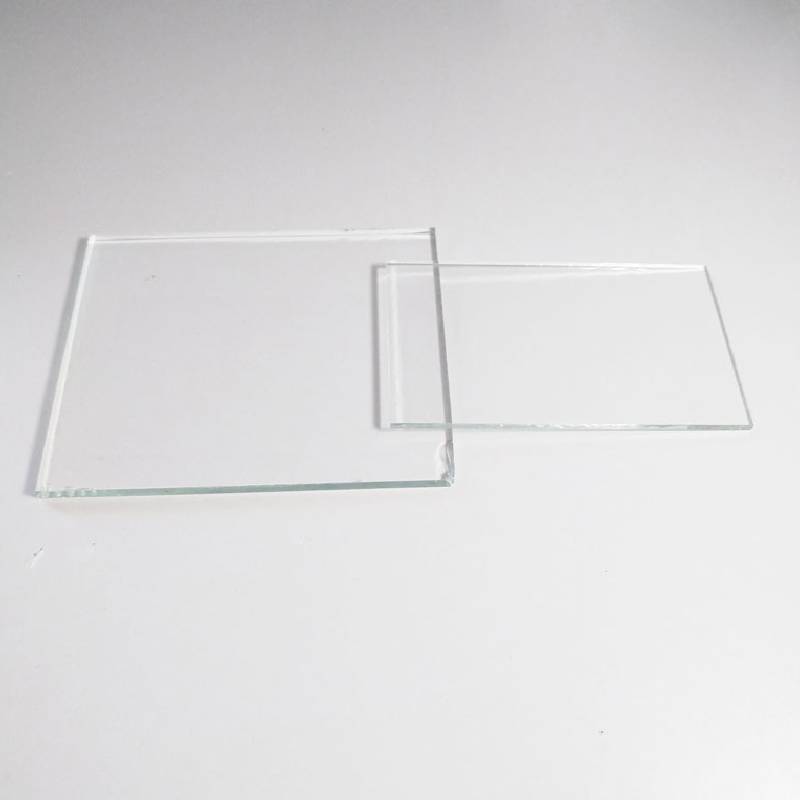

The sheet glass manufacturing process is an intricate and fascinating art, blending centuries-old techniques with cutting-edge technology. Perfecting this process comes with its unique challenges, requiring a deep understanding of both materials and mechanisms involved. Here, we delve into the nuances of these methods, demonstrating expertise and insights that set a high standard for production quality.

One of the most defining and revolutionary techniques in sheet glass production is the float glass process. Developed in the mid-20th century, this method dramatically altered the landscape of glass manufacturing by enabling the production of perfectly smooth and uniform glass panes. The process begins with raw materials silica sand, soda ash, and limestone, which are meticulously weighed and mixed to form a batch. This blend is then heated in a furnace at temperatures soaring above 1700°C. Here, the materials melt to form a molten glass mixture.

What makes the float glass process distinct is its next phase—the floating phase. The molten glass is poured onto a bath of molten tin, a metal that remains in a liquid state at higher temperatures than glass. Because glass does not dissolve in tin and will not mix with it, the glass floats effortlessly on the molten metal. As it spreads over the liquid tin's surface, gravity and surface tension ensure that a perfectly flat glass ribbon forms without the need for mechanical smoothing. This ribbon is controlled to a desired thickness through a precise manipulation of the tin bath and cooling conditions.

Following formation, the glass ribbon enters a lehr, a long chamber where it undergoes controlled cooling, known as annealing. This is crucial to alleviate internal stresses formed during the rapid cooling of the glass ribbon, hence preventing future shattering or breaking. The slow and measured reduction in temperature is a critical stage where expertise is key—imbalances can adversely impact the integrity and transparency of the glass.

sheet glass manufacturing process

Automation plays an authoritative role in quality assurance during this process. State-of-the-art sensors and real-time monitoring systems meticulously track the thickness, flatness, and optical quality of the glass as it moves through different stages. This ensures that the final product not only meets industry standards but also exceeds expectations for clarity and uniformity. Additionally, waste is minimized through innovative recycling techniques, where offcuts and imperfect pieces are fed back into the system, promoting sustainability.

Trust in the manufacturing process is fortified through rigorous testing. Each sheet of glass undergoes stress tests, scratch resistance evaluations, and visual inspections. Producers also engage in continuous research and development, seeking new advancements that offer enhanced durability and novel functional properties, such as UV resistance or self-cleaning finishes.

Product innovation does not cease here—manufacturers explore how variations in the basic recipe or process conditions might yield specialized glass for specific applications—from bulletproof to energy-efficient glazing. This broad utility exemplifies the sheet glass manufacturing process’s adaptability and significance across different industrial sectors, solidifying its place as a cornerstone of modern construction and design.

Despite being a well-oiled machine, the industry does not rest on its laurels. It continuously adapts to incorporate eco-friendly practices and perhaps even more advanced technologies like AI for even greater precision. Thus, the sheet glass manufacturing process remains a testament to human ingenuity and an indispensable part of modern human life.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu