Designing Toughened Glass An Overview

Toughened glass, also known as tempered glass, has emerged as a pivotal material in modern architecture and design. It is engineered for enhanced strength, safety, and thermal performance, making it ideal for various applications, from facades to interior elements. The design and production of toughened glass are complex processes that contribute significantly to its unique properties. In this article, we will delve into the design aspects, manufacturing techniques, applications, and advantages of toughened glass.

Understanding Toughened Glass

Toughened glass is created through a specific process that involves heating the glass to very high temperatures and then rapidly cooling it. This thermal treatment increases the glass's strength compared to standard untreated glass, making it more resistant to impact and thermal stress. When broken, toughened glass shatters into small, blunt pieces, reducing the risk of injury. These innate safety features make toughened glass a preferred choice in many design scenarios.

Design Principles

When designing with toughened glass, there are several key principles to consider. Firstly, the thickness and size of the glass play a crucial role in its performance. Designers must calculate the expected loads and stresses based on the application, whether it be structural glazing, balustrades, or shower screens. The selected thickness should align with safety standards while maintaining aesthetic appeal.

Secondly, the design must account for thermal expansion and contraction. As toughened glass is subjected to temperature fluctuations, proper allowances must be made to accommodate movement without causing stress fractures. This is particularly important in environments where direct sunlight might hit the glass surfaces, leading to uneven heating.

Moreover, the integration of toughened glass with other materials can enhance both strength and appearance. Designers often combine glass with metals, wood, or composites to create stunning visual contrasts while ensuring structural integrity. The use of framing systems, supports, and isolators are carefully considered to maintain the design aesthetic while maximizing the glass’s inherent strength.

Manufacturing Techniques

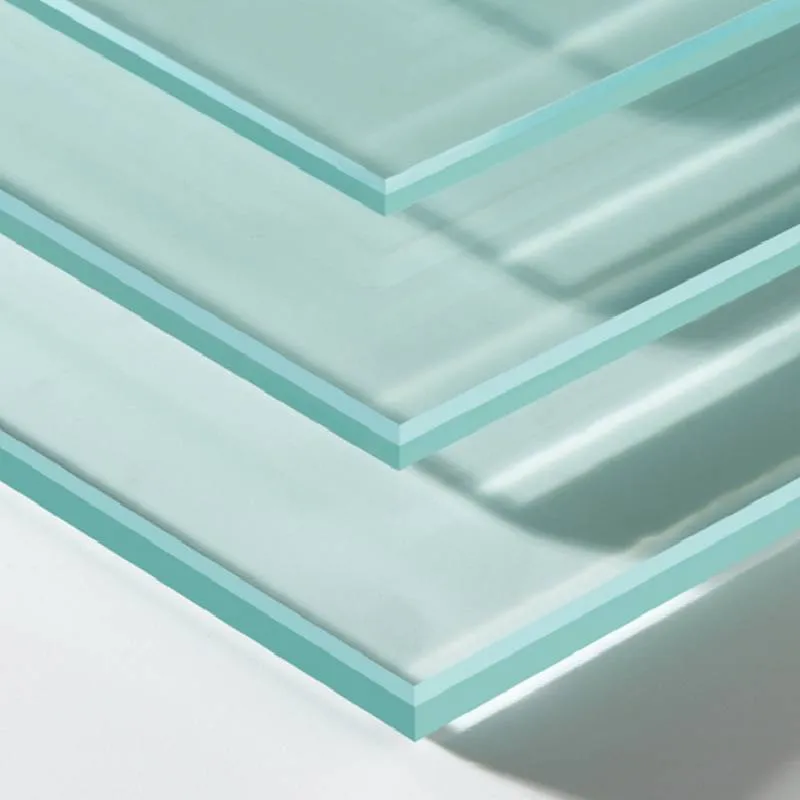

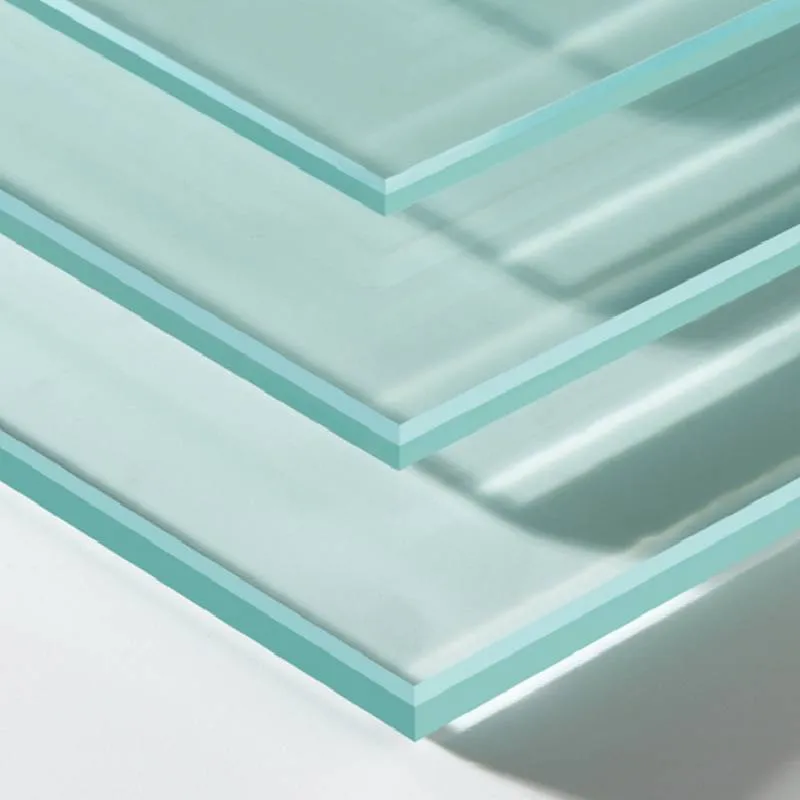

design toughened glass

The manufacturing process of toughened glass consists of several steps. First, raw glass is cut to the desired dimensions and then subjected to a heating process in a furnace. The glass is heated to temperatures around 620 to 680 degrees Celsius (approximately 1148 to 1256 degrees Fahrenheit). Following this, it undergoes rapid cooling using powerful jets of air. This cooling process, known as quenching, is critical as it creates the compressive stresses that give toughened glass its strength.

Quality control is paramount in the production of toughened glass. Manufacturers employ various testing methods to ensure the material meets stringent standards for optical clarity, strength, and thermal stability. Any defects identified during this process can lead to failure, emphasizing the importance of precise workmanship.

Applications and Advantages

The versatility of toughened glass has led to its widespread use in numerous applications. In architecture, it is utilized for windows, facades, and doors, providing both transparency and structural support. In interior design, toughened glass is favored for shower enclosures, partitions, and tabletops due to its sleek appearance and safety features.

Toughened glass also plays a vital role in commercial settings, where it is used in storefronts, balustrades, and atriums. It can withstand high levels of impact and adverse weather conditions, making it a reliable choice for various environments.

The advantages of toughened glass extend beyond safety and strength. Its aesthetic qualities allow for light transmission while providing a seamless, modern look. The ability to customize toughened glass with tints, patterns, or frosted finishes enhances its design potential, catering to diverse architectural styles.

Conclusion

Designing with toughened glass offers immense potential in creating safe, aesthetically pleasing, and functional spaces. As technology advances and manufacturing techniques improve, the possibilities for incorporating toughened glass into innovative designs continue to expand. Whether in residential, commercial, or industrial applications, toughened glass will undoubtedly remain a cornerstone of modern design, benefiting both function and form.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu