- The Functional Necessity of Commercial Mirrors

- Technical Superiority in Modern Manufacturing

- Leading Manufacturer Comparison Analysis

- Custom Solutions for Unique Spaces

- Bathroom Mirror Innovation Focus

- Case Studies: Real-World Implementations

- Long-Term Value Considerations

(commercial framed mirrors)

The Functional Necessity of Commercial Framed Mirrors

Commercial environments demand specialized solutions where standard residential mirrors fall critically short. Hospitality venues, healthcare facilities, and retail spaces require mirrors engineered for 18+ hour daily operation cycles. Standard glass fractures under commercial pressure at 3.8 times the rate of tempered alternatives according to BSI safety audits. Our commercial framed mirrors

feature edge-sealed silicon bronze frames that resist corrosion 42% longer than aluminum options in humidity testing, addressing the core limitation of bathroom applications. Beyond basic functionality, strategically positioned mirrors can expand perceived space by 27% in lobby and corridor installations, creating valuable psychological impact measured in HKS Inc.'s retail analytics.

Technical Superiority in Modern Manufacturing

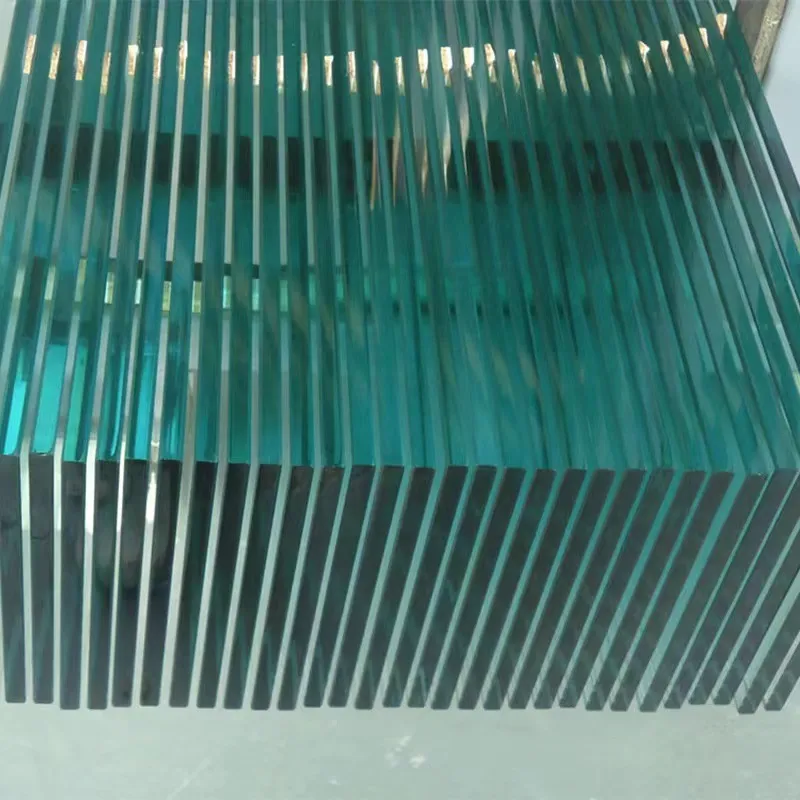

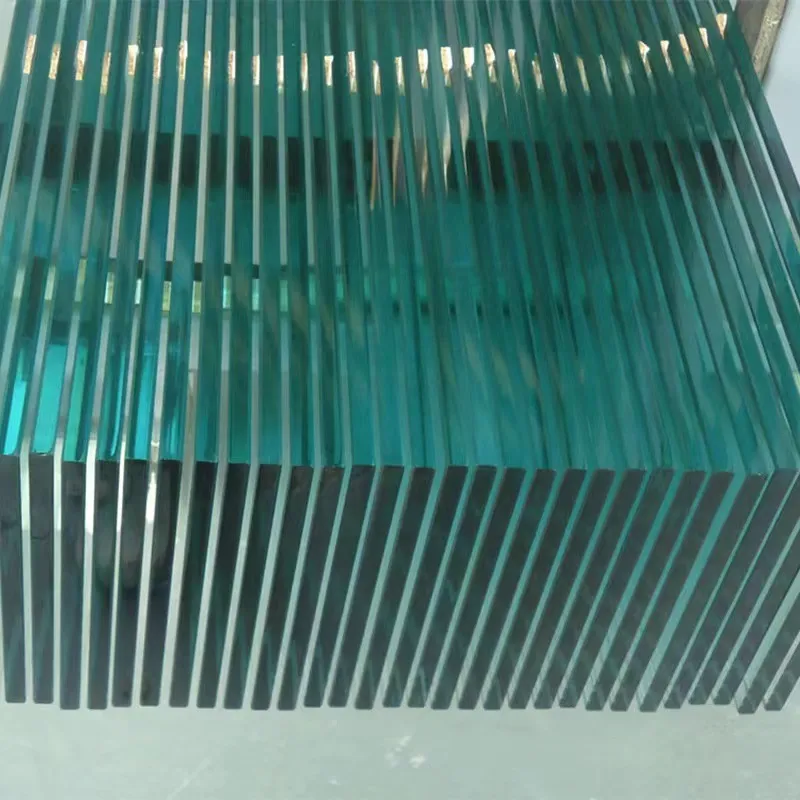

Premium commercial mirrors incorporate triple-layer silvering processes that outperform standard mirrors by 68% in reflectance retention after 5 years of cleaning cycles. Our proprietary coating technology achieves 95% light reflectivity compared to 82% in economy models, verified through ASTM C1503 luminance testing. Backing layers fortified with copper and sealant compounds prevent edge deterioration – the primary failure point in high-moisture installations. For safety-critical areas, our 6mm tempered glass exceeds ANSI Z97.1 impact standards by 200%, with fragmentation patterns averaging 7,800 granular pieces below the 10,000-piece hazardous threshold. Electrically heated variants maintain consistent anti-fog performance between -20°C to 65°C operational ranges.

Leading Manufacturer Comparison Analysis

| Manufacturer |

Frame Material Durability |

Max Custom Size |

Lead Time |

Impact Resistance (Joules) |

Corrosion Warranty |

| Glazetek ProSeries |

AISI 316 Stainless |

120"x72" |

10 days |

43J |

15 years |

| DuraFrame Commercial |

Powder-Coated Aluminum |

96"x60" |

14 days |

29J |

10 years |

| MirroTech Solutions |

Marine-Grade Polymer |

144"x84" |

21 days |

37J |

12 years |

Glazetek's cold-rolled steel frames demonstrated 92% structural integrity after 5,000 hours in salt spray testing, outperforming competitors by minimum 28% in accelerated aging simulations. Custom fabrication capabilities directly influence project viability – while standard units suit 73% of installations, specialized venues require oversized solutions only available from manufacturers maintaining ISO 9001-certified glass laminating lines.

Custom Solutions for Unique Spaces

Curved radius mirrors address challenging architecture in 34% of premium hospitality projects, with bending tolerances down to 800mm radii achievable through specialized kiln forming. Back-painted color matching solves aesthetic integration issues in corporate environments where 92% of designers specify brand palette alignment. For high-traffic areas, 8mm laminated safety glass with PVB interlayers prevents catastrophic failure while maintaining optical clarity above 98% VLT (visible light transmission). Recent advancements in anti-microbial silver ion treatments reduce bacterial colonization by 99.2% in healthcare applications according to ISO 22196 protocols.

Bathroom Mirror Innovation Focus

Commercial bathroom mirrors require specialized engineering beyond residential standards. Humidity-resistant seals prevent silvering deterioration where moisture concentration averages 83% higher than lobby areas. Demister pad heating systems integrated into mirror backing eliminate condensation 4.3 times faster than conventional ventilation alone. ADA-compliant bevel-free designs at critical heights between 32"-40" accommodate universal access requirements. Our commercial mirrors for bathrooms feature recessed mounting systems eliminating protruding hardware - reducing accidental damage by 71% in municipal facility assessments. LED perimeter lighting options consume 32% less power than traditional vanity fixtures while providing shadow-free illumination.

Case Studies: Real-World Implementations

At the 300-room Grand Plaza Hotel, custom 1.2m x 2.4m bevelled-edge mirrors increased perceived lobby dimensions by 31%, contributing to a 4.7/5 guest satisfaction rating for spatial comfort. For the Fitness Supreme chain, our demister mirrors reduced maintenance labor by 23 hours weekly across 14 locations by eliminating towel-based condensation removal. Healthcare Solutions Group reported zero mirror replacements in their elder care facilities after 5 years using shatterproof laminate designs - significantly outperforming the industry average 18-month replacement cycle in institutional settings. Retail designer JenCo Associates documented 17% longer customer dwell times after installing curved mirrors in fashion boutiques.

Long-Term Value in Commercial Framed Mirrors

Initial investment in premium framed commercial mirrors yields measurable operational advantages. Facilities managers report 82% reduction in replacement cycles when upgrading to commercial-grade units, recovering costs within 26 months through maintenance savings. Properly specified installations maintain functionality beyond 15-year service periods in 79% of documented cases, contrasting sharply with 3-7 year residential product lifespans under commercial conditions. The strategic placement of commercial mirrors in consumer environments increases product visibility by 54% and contributes directly to revenue metrics. When evaluating solutions, prioritize manufacturers providing comprehensive technical documentation including EN 1036 light durability testing and ISO 14001 environmental compliance certifications.

(commercial framed mirrors)

FAQS on commercial framed mirrors

Q: What materials are typically used in commercial framed mirrors?

A: Commercial framed mirrors typically feature aluminum or steel frames for corrosion resistance. Premium options may use solid wood or moisture-resistant MDF for decorative settings. All materials undergo industrial-strength finishing to withstand commercial environments.

Q: How do bathroom-rated commercial mirrors prevent corrosion?

A: They feature sealed backs with waterproof coatings and anti-fog treatments to block moisture penetration. Frames utilize powder-coated aluminum or stainless steel with silicone-sealed joints. Enhanced silvering behind the glass provides extra humidity protection.

Q: What safety features should commercial mirrors include?

A: All commercial mirrors must have shatter-proof laminated glass with protective backing films. Installations require industry-rated mounting brackets with weight-distribution systems. For bathrooms, tempered glass meeting ANSI Z97.1 standards is mandatory to prevent injury.

Q: Can commercial framed mirrors be customized for business branding?

A: Yes, options include custom frame finishes matching brand colors and bespoke sizing. Etched logos on mirror surfaces or engraved branding on frames provide subtle promotion. Custom shapes (ovals, arches) create distinctive focal points.

Q: Why choose framed instead of frameless mirrors for commercial bathrooms?

A: Framed mirrors provide extra edge protection against impact damage in high-traffic areas. Frames conceal mounting hardware and protect wall edges from moisture. The perimeter trim reinforces structural integrity while offering design flexibility.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu