The Evolution and Impact of Flat Glass Manufacturing

Flat glass manufacturing is a critical segment of the glass industry that plays a significant role in various sectors including construction, automotive, and technology. As an essential material, flat glass is utilized in windows, doors, mirrors, and screens, making it a ubiquitous presence in our daily lives. The technological advancements in this field have transformed production methods, improved glass quality, and expanded applications.

Historical Context

The history of flat glass dates back to ancient civilizations, where rudimentary forms were produced. Through the centuries, techniques evolved, leading to the introduction of sheet glass in the 17th century. However, it was not until the 20th century that large-scale flat glass manufacturing truly emerged, driven by industrialization and urbanization. The development of the float glass process by Sir Alastair Pilkington in the 1950s marked a pivotal moment. This innovative method allowed for the production of high-quality glass with uniform thickness, which revolutionized the industry.

Manufacturing Processes

Today, flat glass is primarily produced using three methods the float glass process, rolled glass process, and drawn glass process. The most common is the float glass process, where molten glass is poured onto molten tin, allowing it to spread evenly and form a flat surface. This method provides exceptional quality and clarity, essential for applications such as architectural glass and automotive windshields.

The rolled glass process, although less common today, produces textured glass by rolling molten glass into sheets. This technique is often used for decorative applications. The drawn glass process involves pulling glass upward from a molten mass, traditionally used for producing thinner sheets suitable for smaller applications.

Technological Innovations

Recent advancements in technology have dramatically enhanced the efficiency and sustainability of flat glass production. Automation and digitalization have streamlined manufacturing processes, reducing labor costs and improving precision. The integration of computer numerical control (CNC) machines has allowed for intricate designs and custom shapes, catering to the growing demand for personalized glass products.

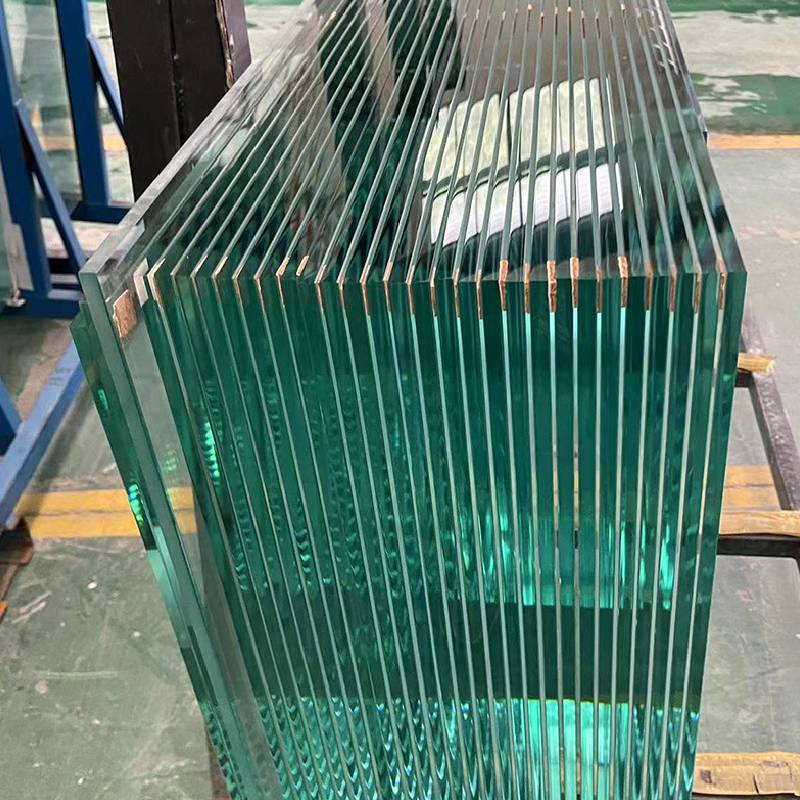

flat glass manufacturing

Additionally, innovations in glass coatings and films have made flat glass more energy-efficient and versatile. Low-emissivity (low-E) coatings, for example, enhance thermal performance by reflecting heat while allowing light to pass through, contributing to energy conservation in buildings. Self-cleaning and anti-fogging coatings are also being developed, making maintenance easier and enhancing safety in automotive applications.

Environmental Considerations

As with many industries, environmental sustainability is a pressing concern in flat glass manufacturing. The production process is energy-intensive and generates greenhouse gas emissions. However, there have been significant strides in implementing eco-friendly practices. Many manufacturers are investing in renewable energy sources and recycling initiatives to reduce their carbon footprint.

Recycling glass, in particular, plays a crucial role in sustainable flat glass production. Utilizing cullet (recycled glass) not only decreases energy consumption but also minimizes waste. The industry aims to increase the recycling rate of glass products, thereby promoting a circular economy.

Future Directions

The future of flat glass manufacturing holds promising prospects. As the global demand for energy-efficient buildings and materials rises, manufacturers are likely to focus on developing high-performance glass products. The integration of smart technologies, such as electrochromic glass that can change its tint based on sunlight exposure, is also gaining traction. These innovations will not only improve aesthetic appeal but also contribute to energy savings and occupant comfort.

Moreover, as urbanization continues in developing countries, the demand for flat glass in construction and infrastructure projects is expected to soar. This trend will spur growth in the manufacturing sector, encouraging investments in research and development to meet the evolving needs of the market.

Conclusion

Flat glass manufacturing is a dynamic industry that reflects the intersection of tradition and innovation. Its evolution from ancient techniques to modern automated processes illustrates the importance of adaptation to meet societal needs. With ongoing technological advancements and a commitment to sustainability, the flat glass manufacturing sector is poised for continued growth and relevance in an ever-changing world. As we move forward, the role of flat glass will undoubtedly become even more integral to our built environments and daily lives.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu