The Craft of Tempered Glass Making

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated to withstand greater stress and impact than regular glass. The process of making tempered glass is a fascinating blend of art and science, requiring precision, skill, and an understanding of material properties. The journey of transforming raw silica sand into robust tempered glass involves several critical steps, each of which contributes to its strength and safety characteristics.

The first stage in tempered glass production begins with the selection of high-quality raw materials, primarily silica sand, soda ash, and limestone. These materials are carefully measured and mixed to create a batch that will be melted in a furnace. The glass-making process involves heating the raw materials at extremely high temperatures—around 1,400 to 1,600 degrees Celsius, where they melt into a molten glass. This phase is crucial for ensuring the uniformity of the glass composition, which directly influences its final strength.

The Craft of Tempered Glass Making

After cooling, the glass is cut into the desired sizes and shapes, ready for the tempering process. Tempering involves heating the glass sheets again to a specific temperature, typically between 600 and 700 degrees Celsius, followed by rapid cooling. This rapid thermal cycling creates a situation where the outer surface of the glass cools and solidifies faster than the inner layers, resulting in compressive stresses on the surface and tensile stresses within the glass. These stresses make tempered glass significantly stronger than untreated glass—up to five times more resilient when subjected to impact or thermal stress.

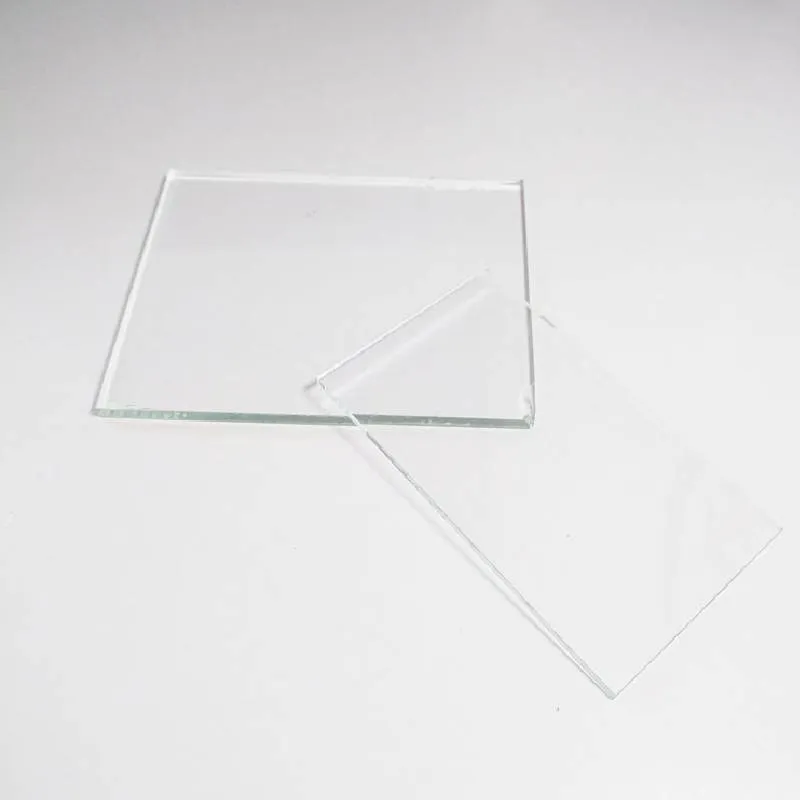

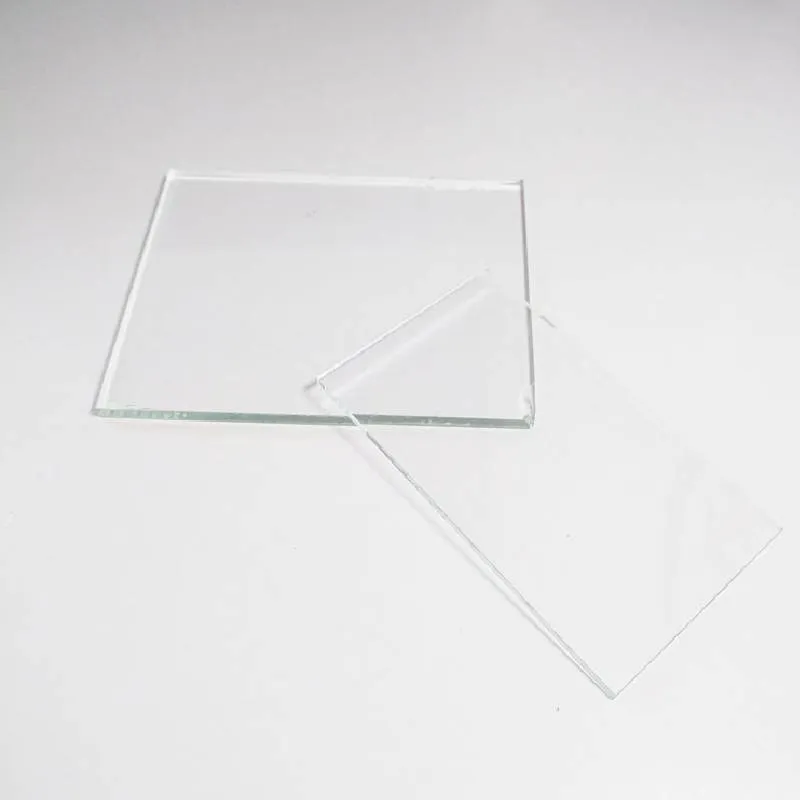

tempered glass maker

One of the most significant benefits of tempered glass is its safety features. In the event of breakage, tempered glass shatters into small, blunt pieces rather than sharp shards, greatly reducing the risk of injury. This characteristic makes tempered glass an ideal choice for a variety of applications, including shower doors, glass doors and tables, and facades of buildings. Additionally, tempered glass is widely used in automotive and architectural applications where safety and durability are paramount.

The tempered glass market has also seen innovations in recent years. Laminated tempered glass, for instance, combines two pieces of tempered glass with a layer of polyvinylbutyral (PVB) to enhance security and sound insulation. Furthermore, advances in technology have led to the development of energy-efficient glass products that minimize heat transfer, contributing to sustainable building designs.

The tempered glass industry is not only about creating a material but also about engineering solutions that meet safety regulations and consumer demands. Glass makers continually refine their techniques and processes, ensuring that they produce high-quality tempered glass that adheres to safety standards and aesthetic requirements.

In conclusion, tempered glass making is a remarkable interplay of tradition and innovation. It combines artistry with engineering to produce a material that is not only visually appealing but also incredibly strong and safe. As the demand for tempered glass continues to grow in various industries, the craft of tempered glass making remains a critical component of modern architecture and design. Whether adorning a skyscraper or serving as a protective barrier in a home, tempered glass represents the pinnacle of glass-making technology.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu