The Cost of Low Iron Glass A Comprehensive Overview

Low iron glass, known for its clarity and distortion-free appearance, has gained popularity in various applications, including architectural features, furniture, and solar panels. Its production, however, involves certain costs that can significantly impact its overall market appeal. Understanding these costs is essential for manufacturers, architects, and consumers alike.

The Cost of Low Iron Glass A Comprehensive Overview

Production Costs

The production of low iron glass begins with the sourcing of raw materials. The primary ingredients include silica sand, soda ash, and limestone, but the purity and quality of these materials are crucial. The cost of high-quality raw materials can be significantly higher than that of standard glass, contributing to the overall expense of low iron glass production. Furthermore, the manufacturing process requires sophisticated technology and equipment to ensure that the iron content remains minimal. This can lead to higher operational costs, including energy consumption and maintenance of specialized machinery.

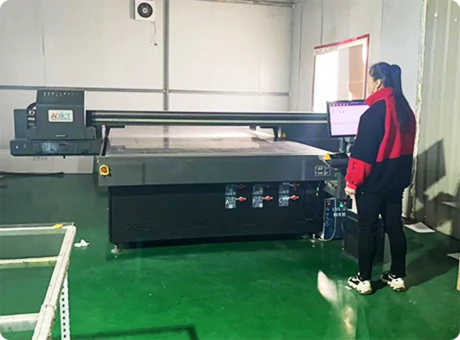

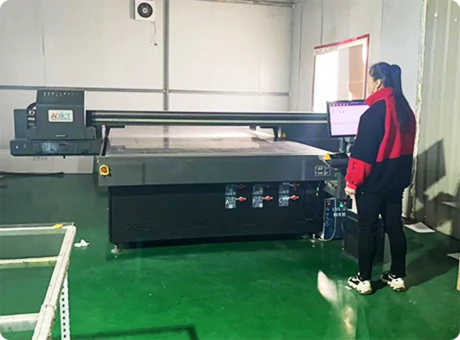

cost of low iron glass

Market Demand and Pricing

The demand for low iron glass has been steadily increasing, particularly due to trends in architectural design that emphasize natural light and visual openness. As more architects and builders opt for low iron glass in their projects, the market price has been driven up. Despite its higher cost compared to conventional glass, its aesthetic and functional benefits often justify the investment in high-end applications. Depending on the thickness, size, and specific requirements of the glass, prices can vary widely, compelling buyers to weigh their options carefully.

Application-Specific Costs

The cost-effectiveness of low iron glass also depends on its intended application. For example, in solar energy applications, the efficiency gained from using low iron glass can result in better energy production, which may offset the higher initial costs over time. In architectural projects, the long-term benefits of enhanced thermal performance and superior aesthetics may lead to higher property values, making low iron glass an attractive option despite the upfront costs.

Environmental Considerations

As sustainability becomes an increasingly important factor in material selection, it's worth noting that low iron glass can have positive environmental implications. Its energy-efficient characteristics can contribute to lower heating and cooling costs in buildings, thereby reducing overall energy consumption. However, the environmental impact of its production, particularly concerning energy use and resource extraction, must also be taken into account when evaluating its cost-effectiveness.

Conclusion

In conclusion, while the cost of low iron glass is generally higher than that of traditional glass due to its raw material quality, production complexity, and advanced applications, its benefits often justify this investment. As the market for glass continues to evolve, a growing understanding of the cost implications associated with low iron glass will be vital for stakeholders making informed decisions. With an emphasis on both aesthetic appeal and functional performance, low iron glass remains a valuable material in modern design and architecture, signaling a trend toward higher-quality, more efficient building practices.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu