Float Glass for Fusing An Overview

Float glass, a staple in the glass manufacturing industry, has gained a specialized application in fusing—a technique that involves melting pieces of glass together to create artistic and functional items. This process not only amplifies the aesthetic qualities of glass but also opens avenues for innovative designs. Let’s delve into the characteristics of float glass that make it ideal for fusing, its applications, and the process involved.

Characteristics of Float Glass

Float glass is produced through a unique manufacturing process where molten glass is floated on top of molten tin. This method provides a smooth and uniform surface, with excellent optical clarity and minimal distortion. The resulting product is strong, versatile, and can be easily cut into desired shapes and sizes. For fusing, these attributes play a crucial role.

One of the standout features of float glass is its low expansion coefficient, which allows it to withstand significant temperature changes without cracking. This characteristic is essential during fusing, as the glass needs to be gradually heated and cooled. Furthermore, float glass is available in a variety of thicknesses and finishes, which allows artists and manufacturers to experiment with different textures and transparency levels in their fused glass creations.

The Fusing Process

Fusing involves placing pieces of glass in a kiln where they are heated to specific temperatures that allow them to melt together. The most common fusing temperature ranges between 1300°F to 1500°F (700°C to 815°C), depending on the type of glass and desired outcome. Float glass is particularly favored for this process due to its ability to melt evenly and adhere well to other glass types.

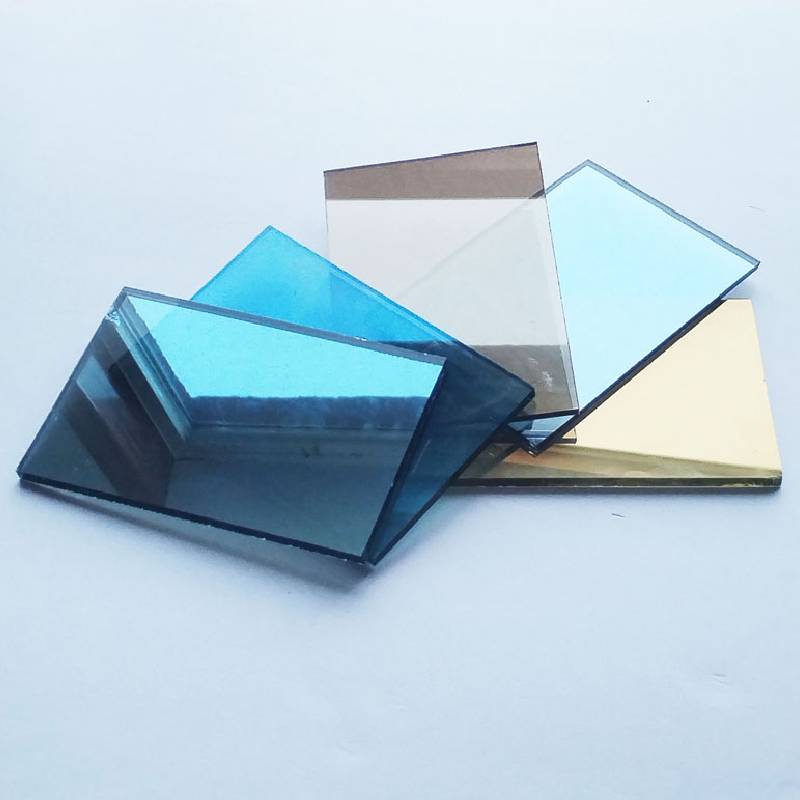

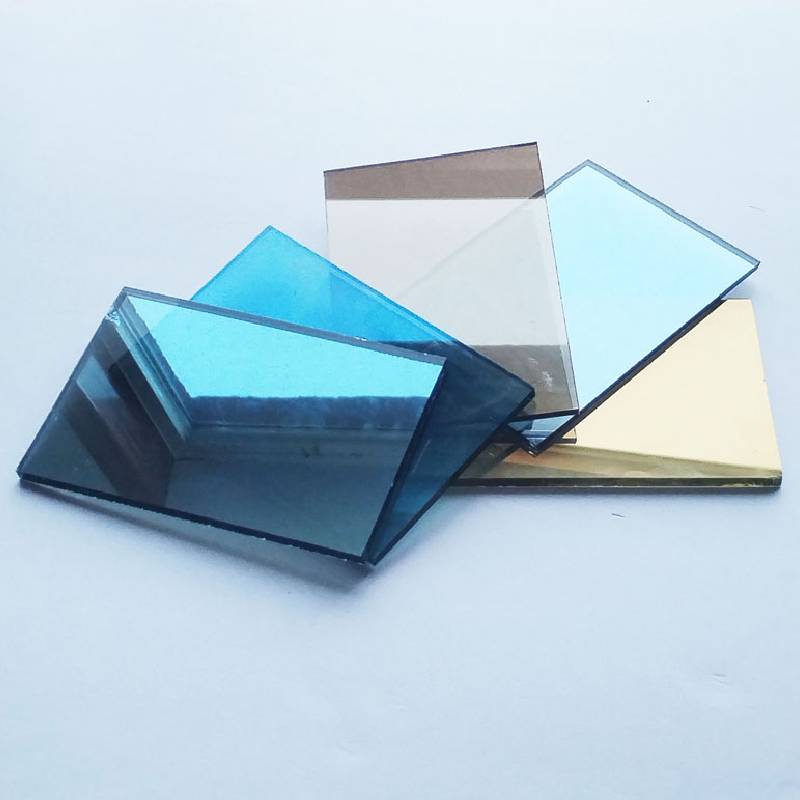

float glass for fusing

Typically, the process begins with selecting float glass sheets that will be cut and shaped to create the desired design. These pieces are usually stacked or layered in such a way that they will fuse correctly when heated. It is essential to pay attention to the compatibility of different glass types, as mismatched coefficients of expansion can lead to issues during cooling, such as cracking.

Once the glass is arranged, it is placed in the kiln for a pre-determined amount of time. After the initial melting phase, the kiln temperature is gradually lowered in a controlled manner, allowing the glass to cool down without introducing stress. This cooling phase is critical, as it ensures the structural integrity of the final piece.

Applications of Fused Float Glass

Fused float glass has a wide range of applications in art and design. Artists create stunning mosaics, embellishments for home decor, and various functional objects like bowls, plates, and window art. The versatility of float glass allows for intricate layering and colorful designs, as different colors and textures can be combined to create breathtaking effects.

In architectural applications, fused glass is often used for decorative panels and installations. The ability to customize designs opens up opportunities for unique solutions in public spaces, office buildings, and residential homes. Additionally, fused glass can be treated for durability, making it suitable for outdoor applications as well.

Conclusion

Float glass is an ideal medium for fusing, marrying strength and clarity with artistic potential. Its manufacturing process lends itself to versatility, while its thermal properties ensure that the final products maintain durability and aesthetic appeal. As artists and designers continue to explore new techniques and applications, the world of fused float glass is bound to grow, offering endless creative possibilities. Whether for artistic expression or functional design, float glass plays an indispensable role in the captivating realm of fused glass art.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu