Float glass, a technologically advanced material, has revolutionized the glass manufacturing industry with its remarkable properties and wide range of applications. Holding unparalleled significance in architectural and automotive industries, float glass is a product of remarkable expertise and precision in glass engineering.

Manufacturing float glass involves a carefully controlled process where molten glass flows over a bed of molten tin, resulting in a smooth, flawless sheet. This process, known as the float glass process, was innovated by Alastair Pilkington in the 1950s and has been a cornerstone of glass production ever since. This method ensures high-quality glass with uniform thickness, and it significantly enhances productivity, making it the preferred choice in the glass industry.

One of the most notable qualities of float glass is its versatility. It can be manufactured in various thicknesses, ranging from ultra-thin panels suitable for use in digital displays, to robust layers ideal for construction purposes. Furthermore, its exceptional flatness and clear, smooth surface make it a perfect base for further processing, such as coating, lamination, and toughening, which extend its functionality in diverse applications.

In architectural contexts, float glass is often preferred for its ability to provide unobstructed views while maintaining structural integrity. Its high light transmission properties make it optimal for buildings aimed at maximizing natural lighting. When used in double glazing, it significantly enhances energy efficiency by acting as an excellent insulator, providing both thermal comfort and reducing energy costs. Architects and builders favor float glass for these intrinsic benefits, which are integral to modern sustainability requirements.

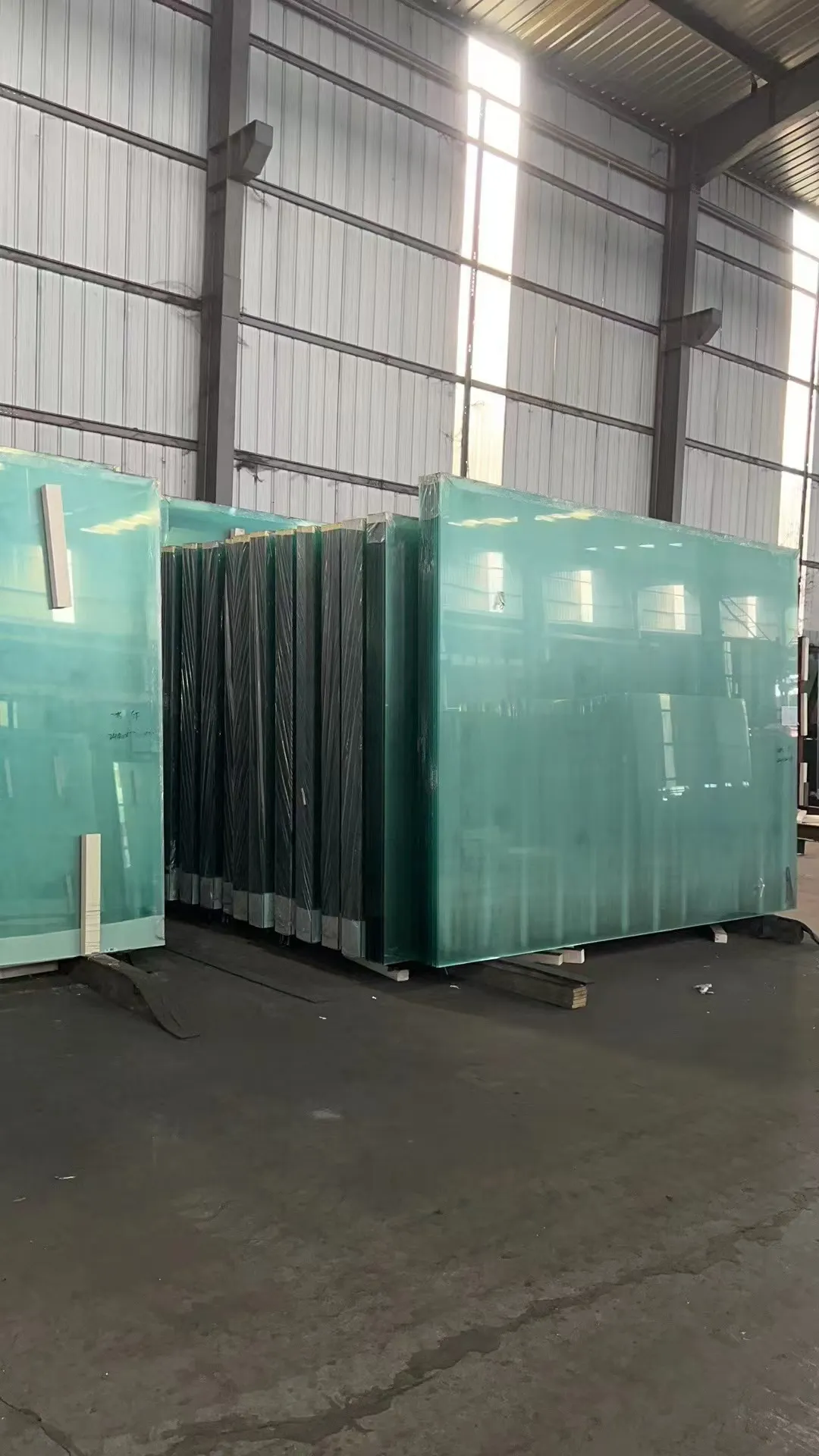

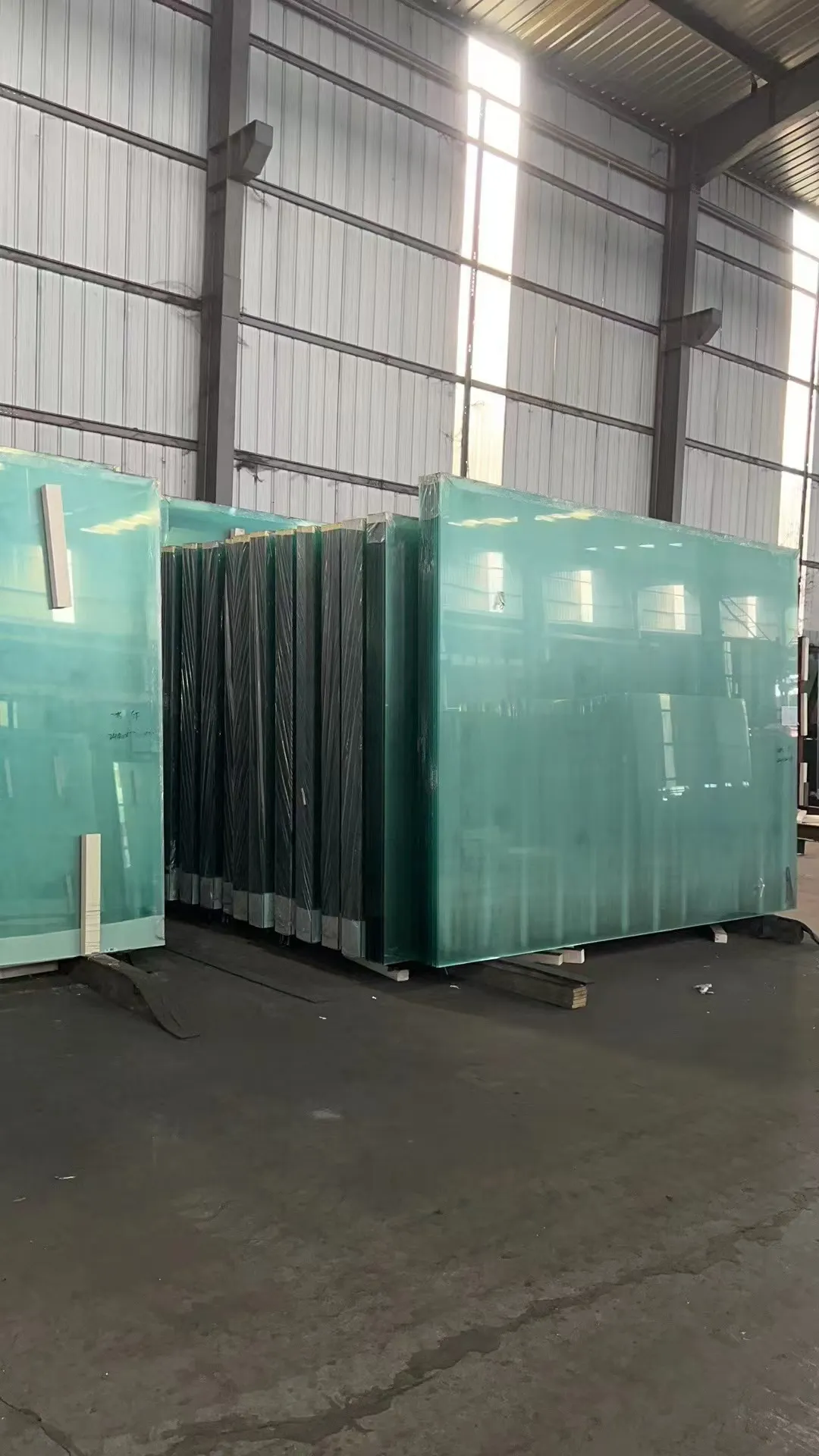

float glass

In the automotive industry, float glass plays a crucial role in safety and design innovation. Laminated float glass is predominantly used in car windshields because of its high impact resistance. In addition to providing safety, its optical clarity and light weight contribute towards improving fuel efficiency and reducing vehicle weight. The material demonstrates reliability and durability, which are essential qualities demanded by automotive engineers.

Beyond construction and automotive uses, float glass is extensively utilized in the manufacture of solar panels, mirrors, and even in specialized fields like aquariums and high-tech interior design. Its adaptability and inherent quality make it suitable for digital projections and smart technologies, further cementing its status as a fundamental material in future innovations.

With continual advancements, the float glass industry is also making strides in reducing its environmental impact. Manufacturers are investing in more sustainable production methods, such as recycling and utilizing waste heat, and are exploring new techniques to decrease the carbon footprint of glass production.

In summary, float glass stands as an emblem of innovative expertise and reliable performance in the glass manufacturing industry.

Its widespread applications, coupled with its sustainable prospects, underscore its importance and multifaceted utility. As industries continue to evolve, float glass is anticipated to remain at the forefront, reflecting ongoing advancements in technology and sustainability, and maintaining its vital role across various sectors.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu