Unlocking the potential of an advanced float glass production line requires not only understanding its complexity but also how it serves as the cornerstone of modern architectural marvels. More than a century after its invention, the float glass manufacturing process still stands as a testament to innovation and precision, pivotal to creating flawless glass surfaces ubiquitous in contemporary design.

The journey of float glass begins with raw materials carefully selected to meet specific standards of purity and quality. Predominantly constituted of silica sand, soda ash, and limestone, these materials are combined with recycled glass cullet to enhance efficiency and reduce the environmental impact of production. In a state-of-the-art facility, precision is paramount as these materials are fed into a furnace reaching temperatures upward of 1500°C. The result is molten glass, a shimmering, amber-tinted liquid poised for transformation.

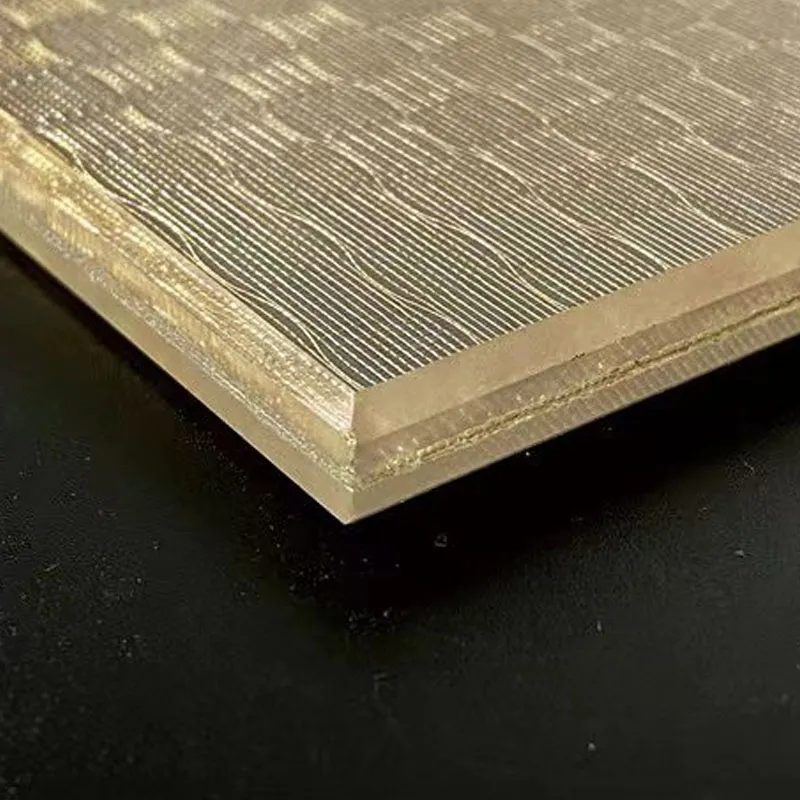

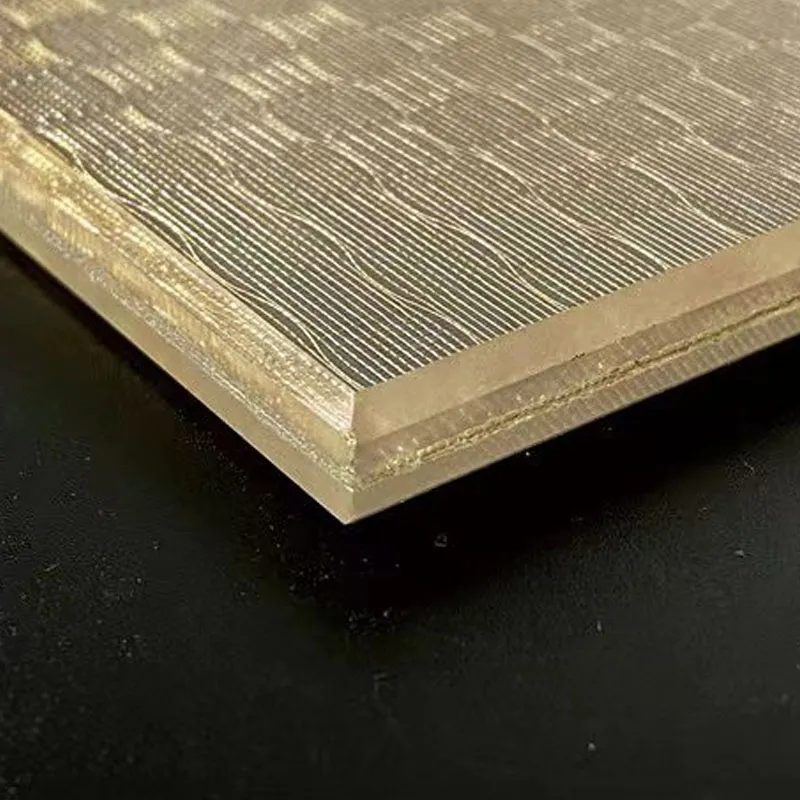

Within a meticulously controlled environment, the molten glass is guided onto a bath of molten tin. Here lies the essence of the float process the denser liquid glass floats seamlessly atop the liquid tin due to their incompatible densities. This floatation ensures both sides of the glass are perfectly flat and parallel, a feat unattainable by traditional means. As the glass moves along the bath, temperature gradients carefully calibrated allow it to cool gradually, affording it uniform thickness and eliminating internal stresses.

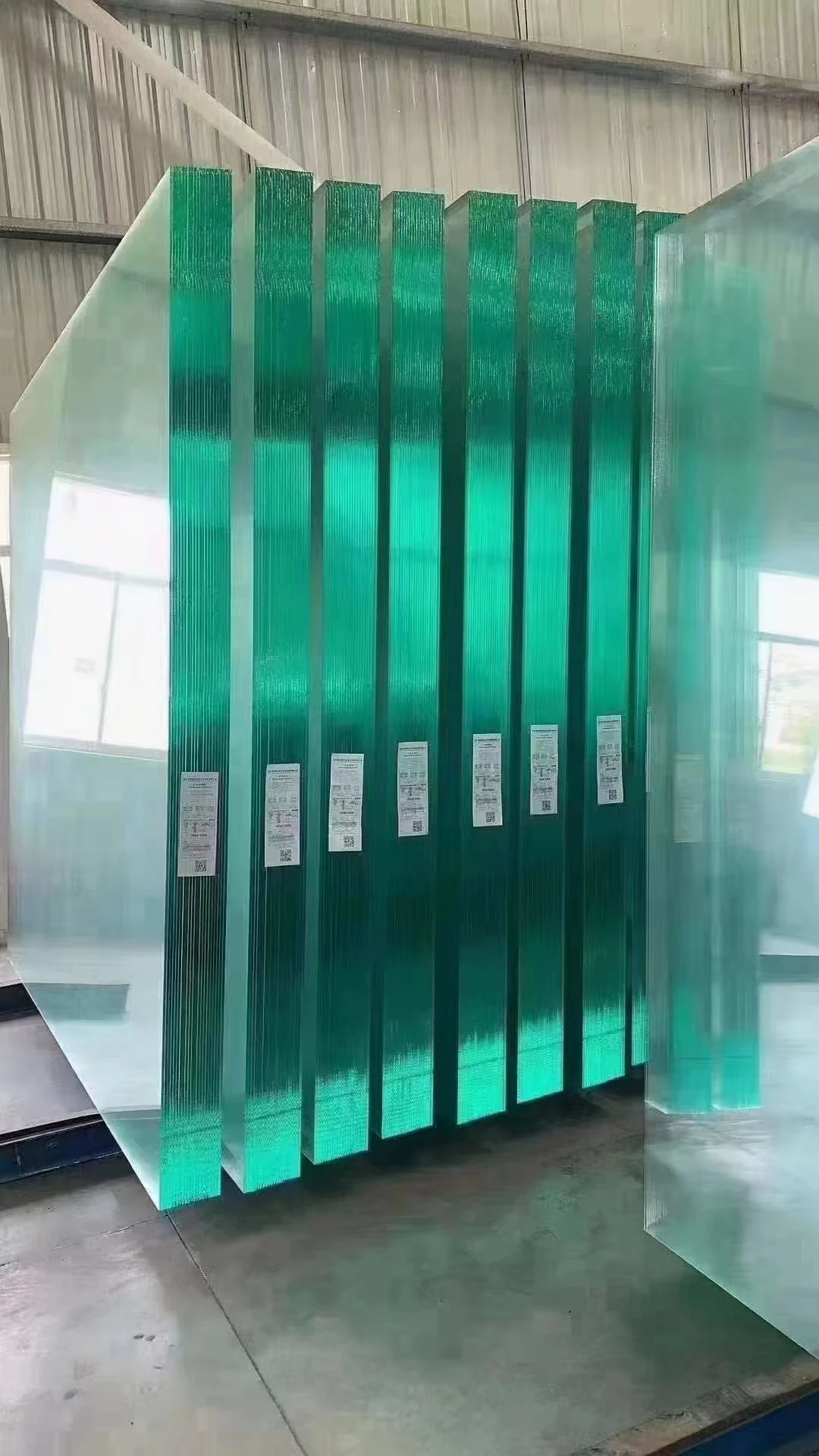

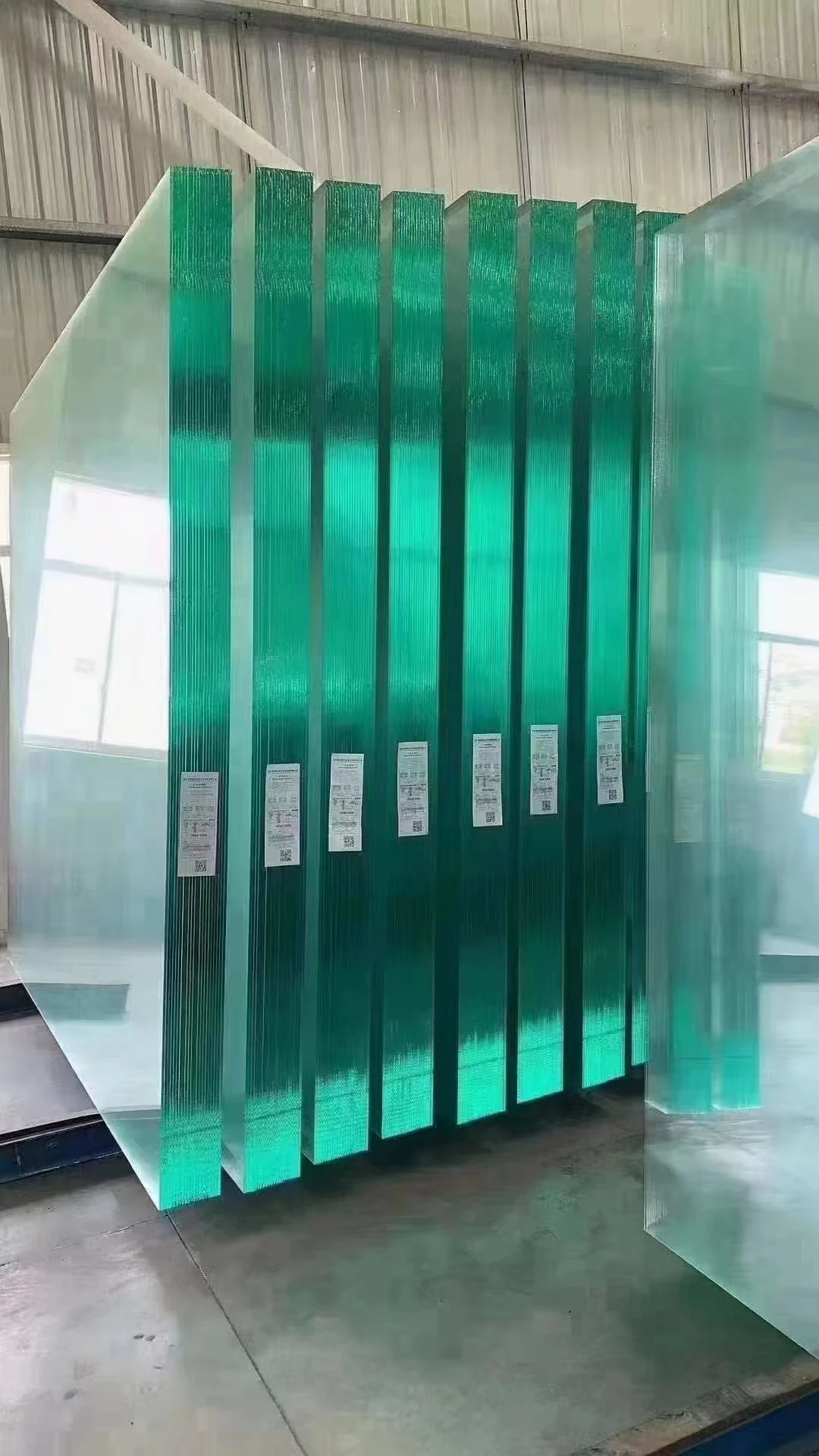

Collaborating with leading-edge technology, today’s float glass production lines are equipped with automated systems that continuously monitor every step of the process. From optical scanners that detect surface defects to precise thickness gauges, technology ensures each sheet not only meets but exceeds stringent quality controls before reaching its destination.

float glass production line

But what distinguishes expert float glass manufacturing is its commitment to sustainability. Leading producers are investing in innovative practices to minimize carbon footprints, reducing energy consumption by employing recycled materials, waste heat recovery, and utilizing renewable energy sources. As pioneers in environmental responsibility, these manufacturers align with global standards, reinforcing their trustworthiness and reliability as key players in sustainable architecture.

The expertise of seasoned professionals in the industry ensures the continuous evolution of float glass techniques, customizing solutions to meet diverse architectural needs. Float glass can be tailored for specific functionalities, whether tempered for extra strength, laminated for safety, or coated for energy efficiency. The versatility of float glass caters to an array of applications, from skyscrapers adorned with reflective façades to minimalist windows that maximize natural light.

Authoritativeness in this field emanates from a legacy of technological prowess and relentless pursuit of excellence. The ability to balance volume production with bespoke orders highlights the operational dexterity these leaders possess, advancing architectural possibilities worldwide. As regulations around energy efficiency and sustainability become more stringent, manufacturers who maintain rigorous standards while innovatively enhancing their offerings continue to lead the charge.

This blend of experience, expertise, and ethical transparency fortifies the float glass production line’s standing in the market. It’s not merely a process of manufacturing; it’s a symbiosis of science, technology, and environmental stewardship that produces a fundamental building block of modern construction. Through this lens, one gains a deeper appreciation for the role of float glass production, one that extends beyond mere function, encapsulating a vision of sustainable innovation.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu