- Market Impact and Growth Trajectory of Decorative Glass Solutions

- Technical Specifications and Advanced Material Properties

- Feature Comparison Among Leading Manufacturers

- Customization Capabilities for Architectural Projects

- Installation Methods and Maintenance Protocols

- Commercial Applications Across Interior Design Scenarios

- Future Trends in Decorative Surface Applications

(antique mirror wall panels)

The Timeless Appeal of Antique Mirror Wall Panels

Decorative glass solutions have revolutionized interior spaces, with antique mirror wall panels

experiencing a remarkable 38% market growth since 2020 according to Architectural Digest. These innovative surface treatments combine historical charm with modern functionality, particularly popular in both residential renovations and commercial hospitality projects. Unlike traditional mirrors, these panels feature specialized chemical treatments that create authentic distressed patinas while providing contemporary benefits like glare reduction.

Major manufacturers now utilize diamond-cut beveling techniques that enhance light refraction by up to 70% compared to standard edges. This technological advancement creates dimensional illusions that make compact spaces appear significantly larger – an ideal solution for urban apartments averaging 800 sq ft. The growing preference for glass wall panels interior applications reflects design psychology principles where reflective surfaces increase perceived spaciousness while adding architectural character without structural changes.

Technological Innovations in Surface Engineering

Modern production of antique mirror panels incorporates silver nitrate saturation processes that increase longevity to 25+ years while maintaining vintage aesthetics. The glass undergoes sequential treatments including acid-etching, silvering, and protective lacquering – a proprietary manufacturing sequence perfected by European glass foundries. These processes ensure the distinctive mercury-glass effect remains stable under varying humidity conditions.

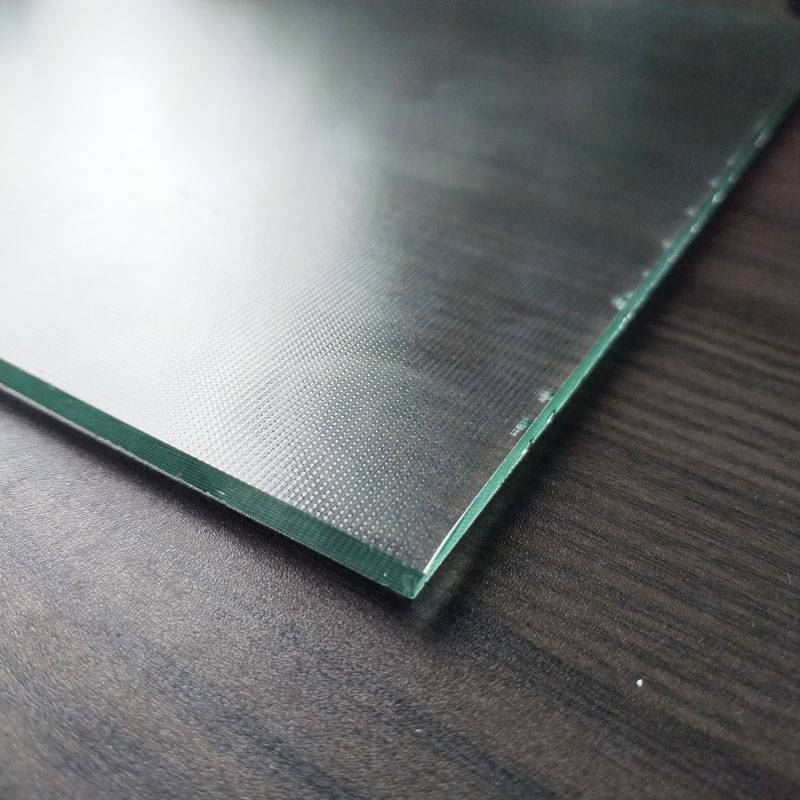

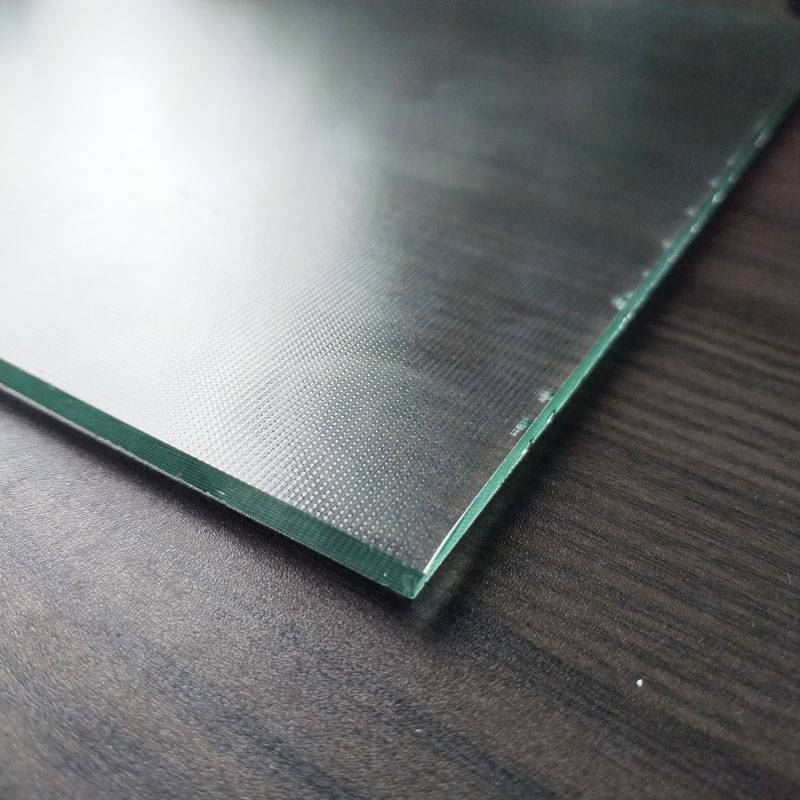

Opaque glass wall panels incorporate silica-based ceramic frits printed directly onto the surface, creating 25% higher opacity than conventional sandblasted alternatives. This technology allows precision pattern definition down to 0.3mm resolution while maintaining full recyclability at end-of-life. Thermal stability testing confirms these panels withstand temperature fluctuations from -30°C to 65°C without optical distortion, making them suitable for installation in diverse environments from spa facilities to arctic climate zones.

Manufacturer Feature Comparison

| Specification |

Vitrum Design |

ArtisanGlass Co. |

Lux Surface Systems |

Verre Decor |

| Panel Thickness (mm) |

8.5 |

6 |

7.2 |

5.8 |

| Max Panel Dimension |

360×144" |

240×120" |

300×126" |

220×110" |

| Light Reflectivity |

93% |

89% |

96% |

85% |

| Custom Pattern Options |

15 standard + bespoke |

7 standard |

22 standard + bespoke |

9 standard |

| Lead Time (weeks) |

6-8 |

4-5 |

8-10 |

3-4 |

| Impact Resistance (Joules) |

28J |

19J |

32J |

15J |

Customization Potential

Contemporary manufacturing enables unprecedented design flexibility with over 90% of orders now requesting custom elements. Leading fabricators utilize CNC waterjet cutting to create intricate border patterns with ±0.01" dimensional accuracy. Surface treatments can be precisely controlled to produce graduated patina effects – deeper distressing at panel edges fading toward untouched clarity at center points. Colorization options extend beyond traditional silvered finishes to include gold, copper, and bronze underlays that complement varied interior palettes.

Commercial applications increasingly incorporate logo integration using ceramic printing processes that withstand commercial cleaning chemicals. The production process allows integration of lighting elements during fabrication – fiber optic strands can be embedded directly within glass layers to create integrated illumination without compromising the antique visual appearance. Back-painted solutions enable coordination with corporate color schemes while maintaining the dimensional depth characteristics of antique mirror wall panels.

Professional Installation and Care

Specialized installation requires precision surface preparation and bonding agents. The recommended application utilizes structural silicone adhesives with minimum 85 psi bonding strength applied in continuous bead configurations. Commercial-grade panels exceeding 4×8' dimensions require supplemental mechanical fixation using discreet chrome-plated standoff hardware with load distribution plates. This dual-mounting approach prevents thermal stress deformation while allowing the necessary 0.25" expansion gap perimeter clearance.

Maintenance protocols involve quarterly cleaning with dedicated ammonia-free glass solutions to preserve silvering integrity. Specialized microfibers with 200,000+ fibers per square inch effectively remove dust particles without surface scratching. For heavily distressed panels with deep crevices, low-pressure steam cleaning prevents moisture infiltration into edge treatments. Professional restoration every 5-8 years can reverse minor oxidation using silver-reactive solutions that deposit fresh reflective layers without panel replacement.

Applications Across Interior Environments

Hospitality venues represent the largest commercial adopters, with luxury hotel chains installing over 450,000 sq ft of decorative glass panels annually according to Hospitality Design Magazine. High-traffic corridors utilize 6mm laminated versions with safety film interlayers to maximize visual impact while meeting Category II impact ratings. Restaurant designers deploy glass wall panels interior concepts in partition systems that maintain spatial openness while providing subtle zone demarcation – particularly effective in establishments averaging 500 sq ft per dining section.

Corporate installations increasingly combine opaque glass wall panels in conference areas to create writeable surfaces on ceramic frit zones alongside clear segments that maintain visual connectivity. Fitness centers and spas install copper-toned versions in wet environments where the antimicrobial properties of copper ions supplement regular sanitation. Retail environments benefit from the light-amplifying properties in back-wall applications where strategic placement can reduce lighting energy requirements by up to 30%.

Design Evolution in Surface Materials

The convergence of traditional craftsmanship with modern technology continues to expand applications for these transformative products. Recent innovations include the development of switchable opacity technology that allows sections to transition from mirrored to transparent states with applied voltage. Sustainability improvements feature prominently in manufacturing processes – leading European facilities now achieve 92% water recycling during silvering operations while utilizing solar thermal energy for glass tempering phases.

Market analysts at Decor Materials International project 54% growth in textured antique mirror wall panels featuring three-dimensional surface patterns produced through kiln-forming techniques. This evolution represents the broader trend toward personalized environmental experiences where functional surfaces contribute significantly to spatial narratives. The continued integration of lighting systems directly within panel structures points toward more holistic design solutions that reduce component complexity while maximizing visual impact in both residential and contract installations.

(antique mirror wall panels)

FAQS on antique mirror wall panels

以下是根据核心关键词“antique mirror wall panels”及其相关词创建的5组英文FAQ问答。每组问答以HTML富文本形式呈现,问题使用H3标签并以“Q:”开头,回答以“A:”开头,控制在三句话内。

Q: What are antique mirror wall panels used for in interiors?

A: Antique mirror wall panels serve as decorative features that add vintage charm and depth to any room. They create an illusion of more space while reflecting light beautifully. Ideal for enhancing homes or offices with a classic or shabby chic style.

Q: How do glass wall panels interior improve modern design?

A: Glass wall panels interior transform spaces by dividing areas without blocking natural light. They contribute to an open, airy feel in living rooms or offices. This versatile solution suits contemporary aesthetics for seamless, elegant partitions.

Q: Why choose opaque glass wall panels for privacy needs?

A: Opaque glass wall panels provide discreet privacy while allowing diffused light transmission. They are perfect for bathrooms or conference rooms, ensuring seclusion without sacrificing brightness. These panels maintain a sleek, modern look while offering functional benefits.

Q: How do you maintain antique mirror wall panels?

A: Clean antique mirror wall panels with a soft microfiber cloth and mild cleaner to prevent scratches. Avoid abrasive materials that could damage the aged finish. Regular dusting keeps them shiny and preserves their reflective appeal.

Q: Can antique mirror and opaque glass wall panels be customized?

A: Yes, both antique mirror and opaque glass wall panels can be tailored in size, texture, or pattern. Custom options allow them to fit specific interior themes, from minimalist to ornate designs. They offer versatile solutions for unique decorative statements.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu