Understanding Clear Annealed Float Glass

Clear annealed float glass is a fundamental building material renowned for its clarity, versatility, and durability. As an integral component in various architectural and industrial applications, it plays a crucial role in modern construction and design. This article delves into the properties, production process, applications, and benefits of clear annealed float glass, shedding light on why it remains a staple in various industries.

What is Clear Annealed Float Glass?

Clear annealed float glass is manufactured through the float glass process, which involves floating molten glass on top of molten tin. This method yields a flat and even surface, resulting in glass of exceptional clarity with minimal distortion. The term annealed refers to the heat treatment process that the glass undergoes after being formed. This process allows the glass to cool slowly, relieving internal stresses and ensuring uniform thickness. The result is a product that is both aesthetically pleasing and structurally reliable.

Properties of Clear Annealed Float Glass

One of the most notable characteristics of clear annealed float glass is its outstanding optical clarity. It offers high light transmission rates and low levels of distortion, making it ideal for applications where visibility is paramount. Additionally, clear float glass has a smooth surface that enhances its transparency, making it a preferred choice for windows, facades, and display cases.

The physical properties of the glass also make it a robust option for various environments. Clear annealed float glass is resistant to environmental stresses, including humidity and temperature fluctuations. When properly handled and installed, it can endure significant pressure and impacts, although it is not as strong as tempered or laminated glass, which are specifically designed for high-stress applications.

The Production Process

The production of clear annealed float glass begins with the melting of raw materials, primarily silica sand, soda ash, and limestone, at high temperatures in a furnace. Once the materials are melted, the molten glass is poured onto a bed of molten tin, where it spreads out to form a uniform thickness. The glass floats on the tin, allowing for the creation of perfectly flat sheets.

Subsequently, the glass is slowly cooled in a controlled environment, a process known as annealing. This step is crucial, as it prevents internal stresses that could lead to breakage. After annealing, the glass is cut into various sizes based on the specific needs of customers. It may also undergo additional processes like polishing or coating, depending on its intended use.

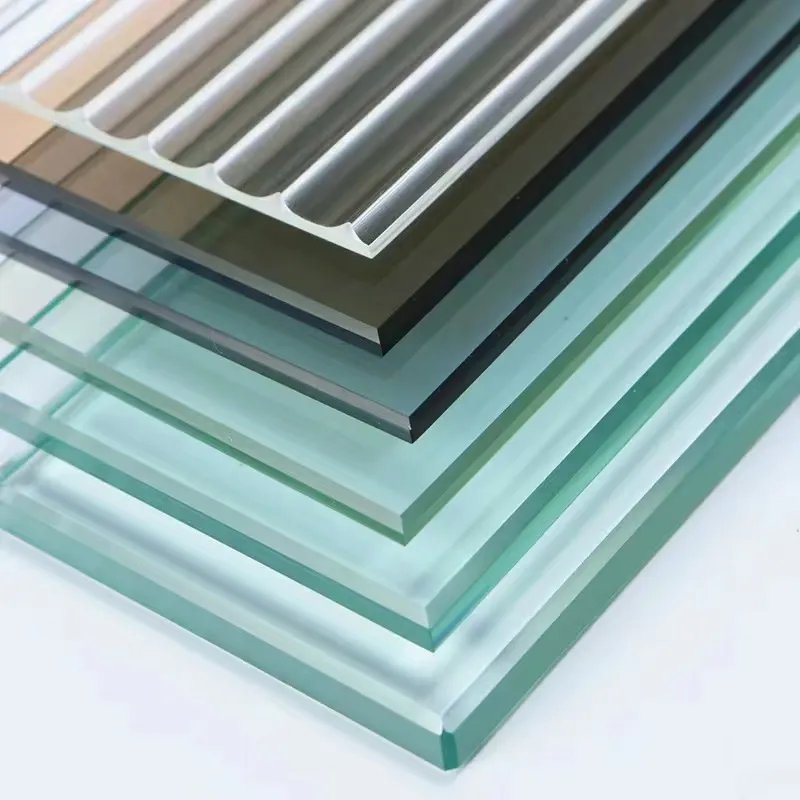

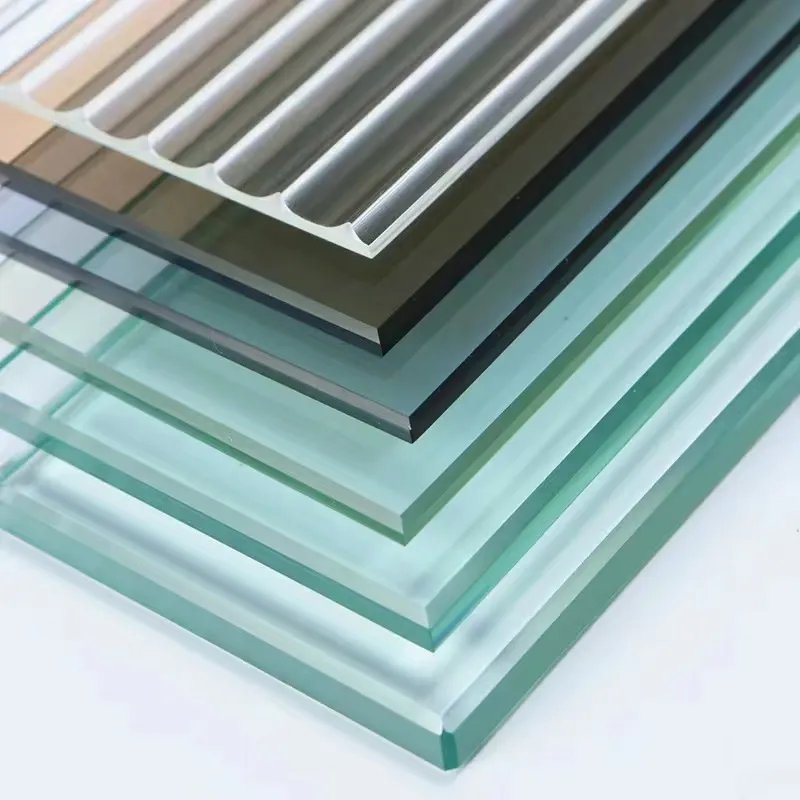

clear annealed float glass

Applications of Clear Annealed Float Glass

The versatility of clear annealed float glass allows it to be used across a broad spectrum of applications. In the architectural domain, it is commonly utilized for windows, glass doors, and curtain walls, offering unobstructed views and natural light. Furthermore, its aesthetic appeal makes it a popular choice for interior applications like glass partitions and shower enclosures.

In the automotive industry, clear float glass is used for windshields, sidelites, and rear windows, where safety and visibility are crucial. The glass is also widely employed in the manufacture of furniture, such as tabletops and shelving, where its sleek look enhances the overall design.

Additionally, clear annealed float glass has a substantial presence in the packaging industry. It is used for producing jars and bottles, providing a safe and aesthetically pleasing way to package food and beverages.

Benefits of Using Clear Annealed Float Glass

The choice of clear annealed float glass comes with numerous benefits. Its high clarity and light transmission make spaces feel open and bright while enhancing aesthetic appeal. Moreover, the ease of fabrication allows manufacturers to create various shapes and sizes, catering to diverse design needs.

Another significant advantage is the glass's ability to be recycled. As a sustainable material, clear annealed float glass can be melted down and reformed into new glass products, reducing waste and minimizing environmental impact.

Conclusion

Clear annealed float glass remains an essential material in contemporary architecture and design. Its unique combination of clarity, strength, and versatility makes it suitable for a myriad of applications, from windows to furniture. As industries evolve and the demand for innovative materials grows, clear annealed float glass is poised to remain a cornerstone in construction and design for years to come. Whether in residential, commercial, or industrial contexts, this glass not only meets functional requirements but also adds to the beauty and integrity of the built environment.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu