- Overview of Toughened Glass Production

- Key Stages in Float Glass Manufacturing

- Tempering Process: Heat Treatment and Quenching

- Technical Advantages Over Conventional Glass

- Manufacturer Comparison: Core Metrics and Certifications

- Custom Solutions for Diverse Industrial Needs

- Applications and Case Studies of Tempered Glass

(process of making toughened glass)

Understanding the Process of Making Toughened Glass

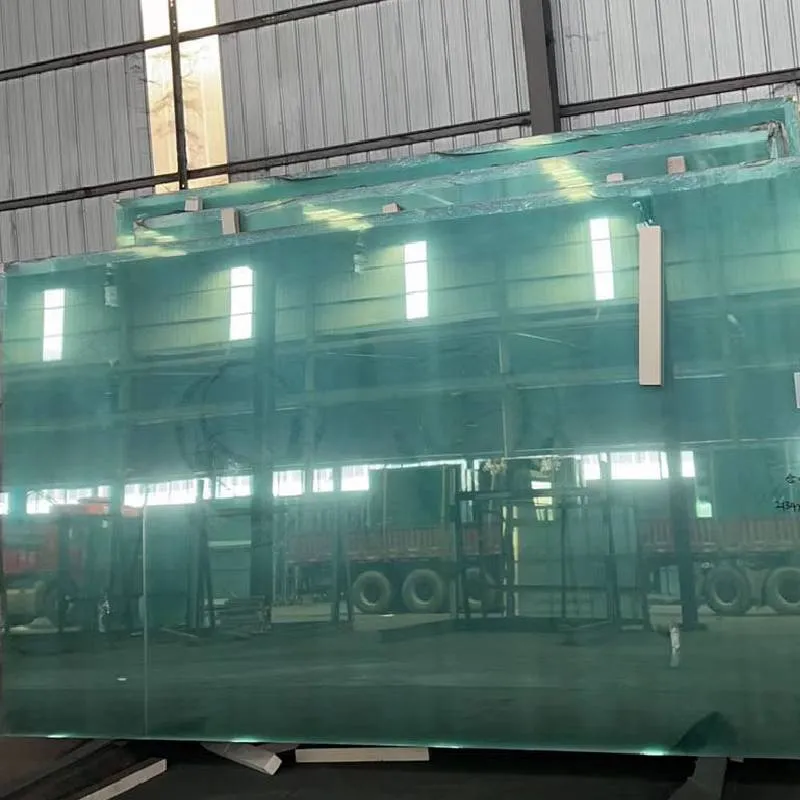

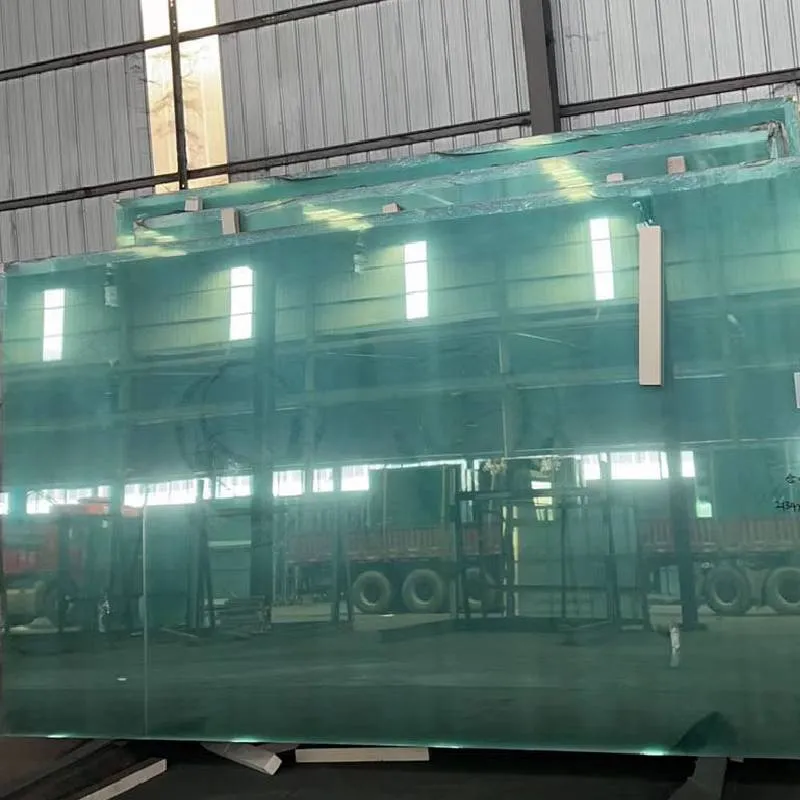

Toughened glass, also known as tempered glass, undergoes a rigorous manufacturing process to achieve its signature strength and safety features. The journey begins with high-quality float glass, which is cut, shaped, and edged to precise specifications. Before tempering, the glass must be thoroughly cleaned to eliminate impurities that could compromise structural integrity. This preparatory phase ensures uniformity, a critical factor for consistent thermal treatment later.

Critical Phases in Float Glass Production

The float glass making process involves melting raw materials (silica sand, soda ash, limestone) at 1,500°C, followed by floating molten glass on a bed of tin to create a flawless, flat surface. Key parameters include:

- Temperature control within ±2°C during annealing.

- Thickness tolerance of ±0.2mm for premium-grade output.

- Optical clarity tested to ASTM C1036 standards.

Heat Treatment and Rapid Quenching Mechanics

During the tempered glass making process, pre-cut float glass is heated to approximately 620°C, just below its softening point, then rapidly cooled via high-pressure air jets. This creates surface compression (10,000–15,000 psi) and edge compression (≥9,700 psi), enhancing breakage resistance by 4–5x compared to annealed glass. The quenching phase’s speed and air pressure directly influence the final product’s mechanical properties.

Performance Metrics and Industry Benchmarks

Tempered glass outperforms standard glass in multiple categories:

| Parameter |

Tempered Glass |

Annealed Glass |

| Impact Resistance |

5x Higher |

Baseline |

| Thermal Shock Limit |

220°C ΔT |

60°C ΔT |

| Fragmentation Pattern |

Diced Particles |

Sharp Shards |

Leading Manufacturers: Capabilities and Certifications

Major producers like Guardian Glass and AGC Glass Europe employ advanced tempering furnaces with automated stress monitoring systems. A comparative analysis reveals:

| Vendor |

Max Thickness |

Tempering Speed |

Certifications |

| Vendor A |

19mm |

90s/sheet |

EN 12150, ANSI Z97.1 |

| Vendor B |

25mm |

120s/sheet |

ISO 9001, GB 15763.2 |

Tailored Solutions for Sector-Specific Demands

Customization options address unique industry requirements:

- Architecture: Laminated tempered glass for hurricane-resistant facades.

- Automotive: Bent tempered side windows with UV-blocking coatings.

- Electronics: Chemically strengthened ultrathin glass (0.3mm) for foldable displays.

Real-World Applications of the Tempered Glass Making Process

From skyscrapers like the Shanghai Tower to smartphone screens, tempered glass’s versatility is unmatched. Case studies highlight:

- 30% reduction in building HVAC costs via solar-control tempered glazing.

- 98% survival rate for tempered automotive glass in crash tests (NHTSA 2022 data).

- Zero reported injuries from glass breakage in 5,000+ installed public partitions.

(process of making toughened glass)

FAQS on process of making toughened glass

Q: What are the basic steps in the float glass making process?

A: The float glass process involves melting silica sand, soda ash, and limestone, then pouring the molten glass onto a bed of molten tin. This creates a smooth, flat surface as the glass cools. The resulting sheet is cut and prepared for further processing.

Q: How does the tempered glass making process differ from regular glass production?

A: Tempered glass starts with standard float glass, which is heated to around 620°C and then rapidly cooled (quenched). This rapid cooling creates surface compression, enhancing strength. Tempered glass is 4-5 times stronger than annealed glass.

Q: What is the purpose of the quenching stage in toughened glass manufacturing?

A: Quenching involves blasting heated glass with high-pressure air jets to cool its surface faster than the core. This creates internal tension and compressive surface stresses. The imbalance gives toughened glass its characteristic strength and safety features.

Q: Why is chemical treatment sometimes used in the tempered glass process?

A: Chemical tempering involves immersing glass in a potassium nitrate bath to replace smaller sodium ions with larger potassium ions. This creates surface compression without thermal treatment. It’s often used for thinner glass or complex shapes unsuitable for thermal tempering.

Q: What safety features result from the toughened glass manufacturing process?

A: The tempering process ensures toughened glass breaks into small, blunt granules instead of sharp shards. This reduces injury risk during breakage. It also improves thermal resistance compared to untreated glass.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu