Float glass, a term frequently encountered within the architectural and construction sectors, represents a groundbreaking innovation that has redefined how modern structures integrate transparency and style. The float glass manufacturing process is not only an engineering marvel but also a testament to human ingenuity, involving the meticulous transformation of raw materials into a seamless, high-quality product.

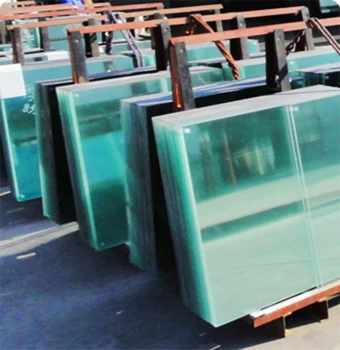

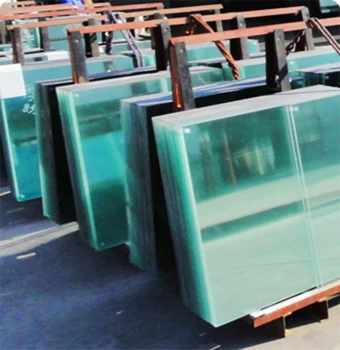

The origins of float glass can be traced back to the mid-20th century, revolutionizing glass production by introducing a process that reduced imperfections and enhanced clarity. This method involves molten glass being poured onto a bed of molten tin, where it spreads out to form a uniform layer. The float process allows for precise control over the glass's thickness and surface quality, resulting in sheets of glass that are remarkably smooth and optically clear.

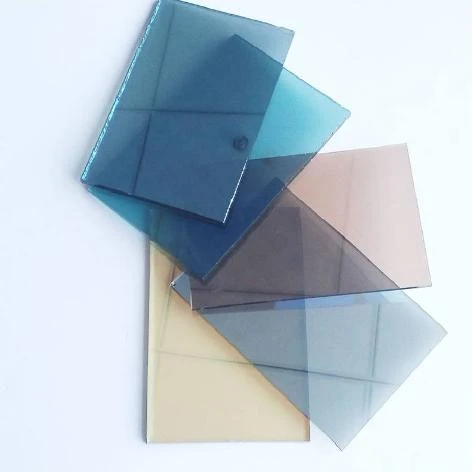

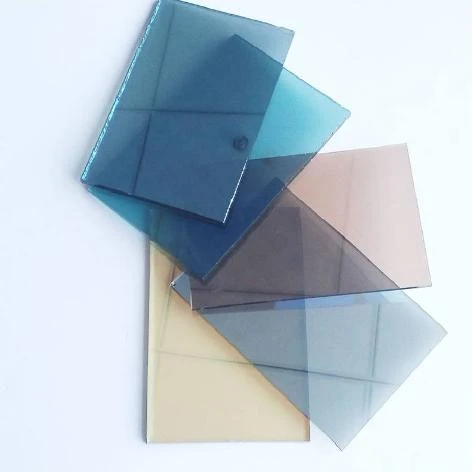

Float glass has widespread applications, owing to its unparalleled qualities. It serves as the fundamental material for windows, facades, mirrors, and even solar panels. Architects and designers favor float glass for its versatility and aesthetic appeal. Contemporary buildings often utilize large panes of float glass to create bright, open spaces while maintaining structural integrity and energy efficiency.

From a technical perspective, float glass properties such as its thermal insulation, soundproofing capabilities, and durability make it a preferred choice for sustainable building practices. Its ability to be tempered or laminated further enhances its safety and performance, making it suitable for environments that demand high resilience.

float glass meaning

Many companies globally, leverage float glass technology to produce specialized products tailored to unique environmental and design challenges. For instance, low-emissivity (Low-E) float glass is engineered to minimize UV and infrared light penetration, optimizing energy usage while maintaining visibility and comfort within the building spaces. Such innovations underscore the commitment to addressing environmental concerns through efficient material usage.

Despite its extensive benefits, working with float glass does require expertise to ensure optimal results. Professionals in the field should be well-versed in handling, installation, and maintenance procedures to preserve the glass's integrity and functionality. Regular inspection and cleaning with appropriate, non-abrasive materials are recommended to retain the glass's clarity and prevent damage.

Float glass represents more than just a construction material; it embodies the principles of modern design and engineering efficiency. Its continued evolution is driven by ongoing research and development efforts aimed at enhancing performance while reducing environmental impact. Organizations and professionals committed to excellence in architecture and construction recognize the value of investing in high-quality float glass products, aligning with both industry trends and consumer preferences.

Understanding the significance of float glass and its applications offers a profound appreciation for this material's role in shaping contemporary architecture. As advancements in manufacturing continue, float glass is poised to contribute significantly to the future of sustainable building practices, supporting a world that seamlessly integrates functionality with aesthetic appeal.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu