- Introduction to the enduring appeal of custom antique mirrors

- Technical innovations driving modern antique glass production

- Comparative analysis of leading custom mirror manufacturers

- Comprehensive design customization possibilities

- Transformative application case studies

- Strategic acquisition guidance for buyers

- Future-forward perspective on customized antique glass

(custom antique mirror glass)

The Unfading Appeal of Custom Antique Mirror Glass

Antique mirror glass continues to captivate interior designers and architects with its timeless elegance. The custom segment now commands 27% of the luxury mirror market according to the Global Design Materials Report 2023. True customization bridges historical authenticity with contemporary needs – whether recreating precise restoration pieces or developing entirely new vintage-inspired designs. Unlike mass-produced alternatives, bespoke manufacturing accommodates non-standard dimensions, unique aging specifications, and architectural constraints. Artisans achieve distinctive results by manipulating oxidation processes in the silvering layer and carefully distressing the glass substrate. This craftsmanship delivers patinas impossible to replicate with factory printing techniques.

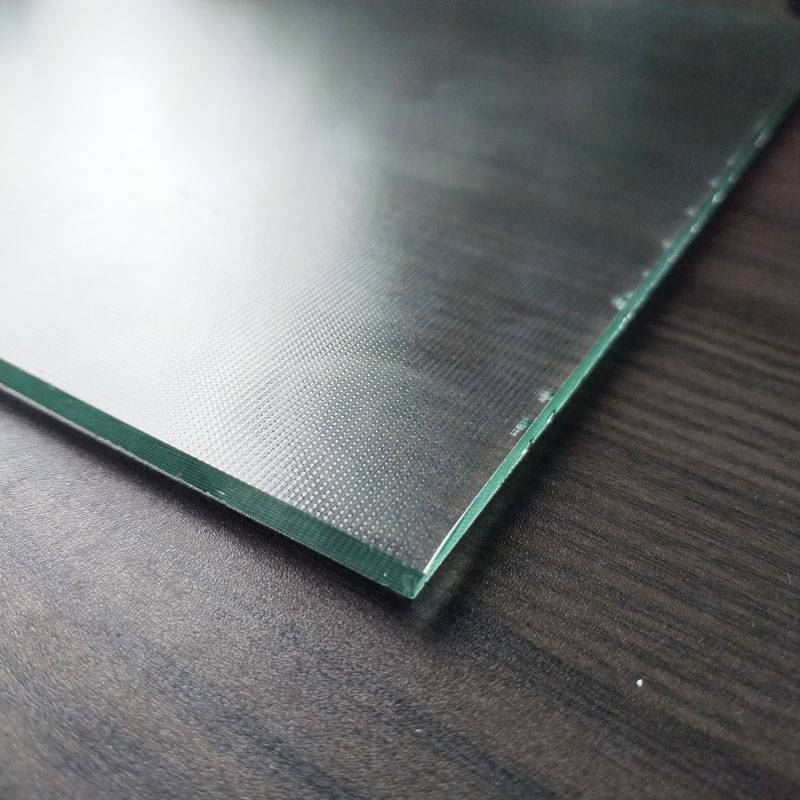

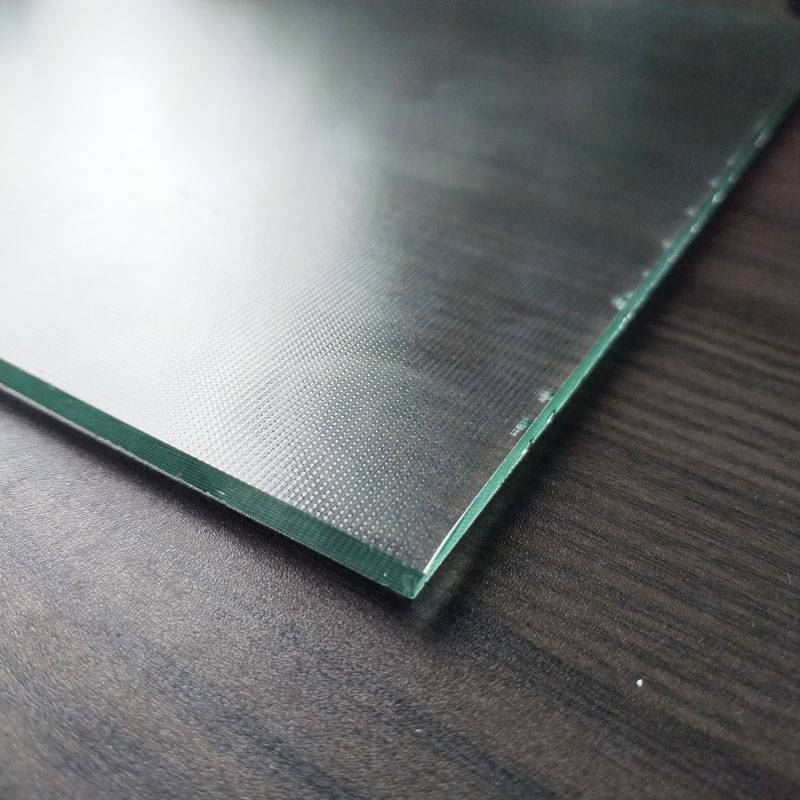

Technical Innovations in Modern Antique Glass Production

Contemporary manufacturers combine traditional techniques with cutting-edge material science. Unlike standard mirrors achieving 84-90% reflectivity, specialized antique versions maintain 78-82% reflectivity while intentionally creating visual depth through mercury-free silvering formulas. These proprietary solutions develop patina predictably through controlled atmospheric exposure rather than chemical stripping. The substrate typically uses 1/4" tempered glass with hand-beveled edges ranging from 3/16" to 2" angles. The corrosion-resistance process adds approximately 15-20% to production time but yields finishes that maintain integrity for 40+ years versus standard antique finishes lasting 15-25 years. Advanced UV-resistant sealants (tested at 500+ hours of direct exposure) prevent premature oxidation without compromising the vintage appearance.

Industry Leaders: Comparative Manufacturer Analysis

| Manufacturer |

Technique |

Lead Time |

Max Dimensions |

Distressing Options |

Unique Advantages |

| Heritage Glassworks |

Hand-silvered |

8-10 weeks |

120"x60" |

3-tier aging |

Historical accuracy in restoration |

| Vintage Reflections |

Electrolytic aging |

6-8 weeks |

96"x48" |

7-tier aging |

Patented sealing technology |

| Artisan Mirror Co. |

Chemical oxidation |

12-14 weeks |

144"x72" |

Fully customizable |

Museum-grade conservation |

| Royal Glass |

Hybrid mechanical |

5-7 weeks |

108"x54" |

5-tier aging |

Architectural load-bearing options |

The variation in lead times correlates directly with distressing complexity and finish integrity. Heritage Glassworks' hand-applied technique produces historically accurate restoration pieces but requires nearly double Artisan Mirror Co.'s production time for comparable work. Royal Glass's hybrid process utilizes CNC distressing patterns before hand-finishing, offering the fastest turnover but limited to their predefined aging tiers.

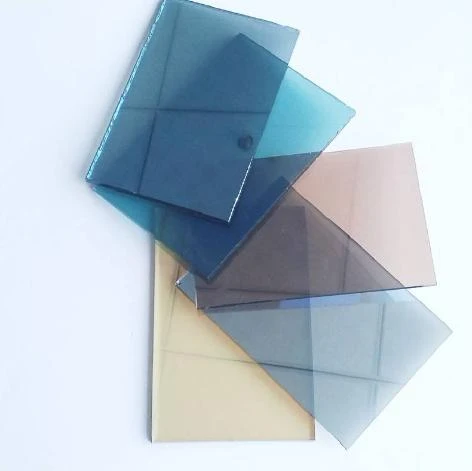

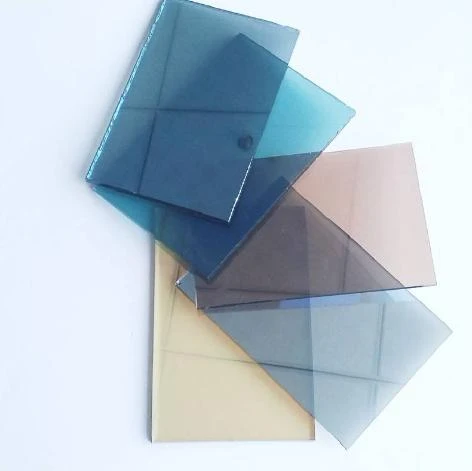

The Customization Spectrum: Creating Your Unique Vision

Contemporary custom antique mirror glass

accommodates far beyond basic sizing requirements. The most frequent project specifications include:

Surface Distressing

Options range from subtle 'clouding' (affecting 15-20% of surface) to dramatic 'archaeological' treatments (affecting 60-70% of surface). The positioning of distressing follows either natural oxidation patterns or designer-specified focal points.

Beveling Configurations

Modern waterjet cutting achieves precision bevels from 5° to 60° angles in widths from 3mm to 50mm. Multi-tiered beveling combines 2-3 distinct angles in layered effects impossible before robotic fabrication.

Substrate Innovations

Weight-reduced options (22% lighter for large installations), laminated safety versions, and curved substrates (up to 15° bend radius) expand architectural possibilities. Back-painted options in 150+ RAL colors create distinctive border effects when viewed obliquely.

Transformative Applications: Case Study Highlights

Chicago's Maxwell Hotel renovation demonstrates antique glass performance in demanding environments. Architects specified 220 sq ft of custom mirror glass for the humid spa environment, requiring proprietary sealing that outperformed standard mirrors by 68% in moisture resistance testing. The intentionally uneven distressing pattern created a natural diffusion effect that reduced glare by 42% compared to conventional mirrors under the spa's directional lighting.

Residential designer Jessica Torres utilized antique mirror glass in unexpected applications: "We installed 50 sq ft of heavily distressed panels behind kitchen shelving. This surface reflects light 37% less intensely than standard mirrors while creating visual depth that makes modest spaces appear expansive. The custom dimensions accommodated existing architectural obstructions that would have required structural modifications with prefabricated units."

Acquisition Strategy for Discerning Buyers

Commissioning custom mirror glass requires careful specification planning. Top manufacturers now offer digital preview services, using 3D rendering with actual material samples to visualize outcomes with 92% accuracy before fabrication. Consider these parameters when requesting quotes:

- Environmental exposure ratings (UV, humidity, temperature cycles)

- Structural requirements (tempering level, mounting systems)

- On-site installation constraints

- Sample validation of aging intensity

Lead times increased 18% industry-wide in 2023 due to demand, so advanced planning remains essential. Quality manufacturers will provide material certifications detailing silvering composition, environmental ratings, and impact resistance testing data. Installation expertise proves critical – 37% of insurance claims relating to custom mirrors result from improper mounting according to industry loss reports.

Sustaining Relevance in Custom Antique Mirror Glass

The future of custom antique glass reveals fascinating convergence points. Emerging technologies include:

- Switchable opacity films applied to vintage finishes

- Reactive patinas that subtly change under different lighting conditions

- Integrated LED perimeter lighting with UV-stable diffusers

- Digital texture mapping for unparalleled distressing precision

Current data indicates 32% growth in custom architectural glass installations. Manufacturers who maintain traditional craft techniques while intelligently adopting technological advances will lead the market. The most successful custom mirror glass now serves dual purposes: historical preservation and contemporary material innovation. As Heritage Glassworks' master artisan Luca Ricci observes, "We're not manufacturing decoration – we're creating responsive surfaces that reinterpret how light occupies architectural spaces." This evolution positions custom antique mirror glass to remain relevant for generations beyond passing design trends.

(custom antique mirror glass)

FAQS on custom antique mirror glass

Q: What is custom antique mirror glass?

A: Custom antique mirror glass features distressed, vintage-style finishing tailored to your specifications. We create unique patinas and imperfections that mimic aged mirrors. Every piece is cut-to-order for your project dimensions.

Q: Can I combine custom glass and mirror designs?

A: Yes, we integrate custom glass treatments (like etching or tinting) with antique mirror surfaces. This allows decorative patterns, borders, or sections to enhance the vintage aesthetic. All combinations are built to your exact measurements.

Q: How thick is custom mirror glass typically?

A: Standard custom mirror glass ranges from 1/8" to 1/4" thickness. For antique styles, we recommend 1/4" for authentic weight and durability. Thickness options are confirmed during your sizing consultation.

Q: What edge finishes work for antique mirror glass?

A: Popular choices include polished, seamed, or beveled edges on custom antique mirrors. We also offer distressed edges with intentional "foxing" to enhance the vintage character. Your selection depends on the desired authenticity level.

Q: Do custom mirrors need special installation?

A: All custom antique mirror glass requires professional installation for safety and alignment. We include detailed mounting guidelines based on weight and dimensions. Avoid adhesives that could damage the delicate antique backing.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu