Reflective glass represents an advanced architectural and industrial material that integrates cutting-edge coating technology for enhanced performance. This comprehensive guide delves into the latest trends, technical parameters, manufacturing process, application scenarios, and market comparison of reflective glass, emphasizing the 5mm reflective glass dark green reflective glass.

Reflective Glass Industry Overview & Current Trends

In recent years, the global reflective glass market has seen robust growth—market research by Grand View Research values the sector at over USD 5.14 billion in 2023, with a projected CAGR of 7.6% through 2030. This trend is fueled by increasing demand for energy-efficient, sustainable construction materials, urbanization, and architectural aesthetics across high-rise buildings, commercial complexes, and specialized industrial facilities.

- Asia-Pacific remains the dominant reflective glass supplier, accounting for more than 55% of global output.

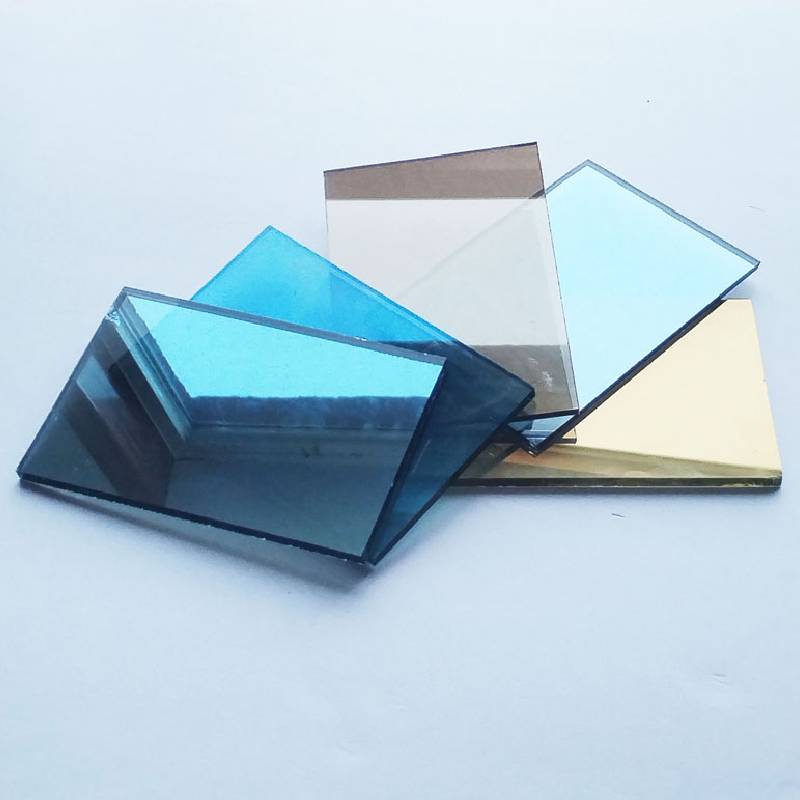

- Technological advancements now permit precise optical control, heat insulation, and customized tints—such as blue reflective glass, black reflective glass, and bronze reflective glass.

- OEM and custom solutions are gaining traction among architects seeking design flexibility and performance.

Key Technical Parameters of Reflective Glass

| Type |

Thickness (mm) |

Light Transmittance (%) |

Reflectance (%) |

Solar Factor (g) |

Color |

| 5mm Reflective Glass |

5 |

14–26 |

30–44 |

0.28–0.36 |

Dark Green / Blue / Black / Bronze |

| 6mm Blue Reflective Glass |

6 |

19–27 |

34–42 |

0.29–0.33 |

Blue |

| 8mm Bronze Reflective Glass |

8 |

21–28 |

36–49 |

0.30–0.38 |

Bronze |

| 5mm Black Reflective Glass |

5 |

12–16 |

40–49 |

0.25–0.31 |

Black |

| 5mm Dark Green Reflective Glass |

5 |

17–23 |

37–46 |

0.28–0.33 |

Dark Green |

Reflective Glass Price Analysis (2024)

- 5mm Reflective Glass Price: $8.2–$13/m2

- 5mm Dark Green Reflective Glass Price: $10–$15/m2

- Blue Reflective Glass Price: $11–$17/m2

- Black Reflective Glass: $12–$19/m2

- Bronze Reflective Glass: $11–$14/m2

Manufacturing Process for Reflective Glass

1. Raw Material Selection

(High purity silica, soda, dolomite, coloring agents)

→

2. Float Glass Production

(Molten glass floats on molten tin bath; forms uniform sheets)

→

3. Annealing & Cutting

(Slow cooling to relieve stress, cut to specification)

→

4. Reflective Coating Deposition

(Online CVD: Metal oxides deposited at 600–650°C for strong adhesion)

→

5. Quality Inspection & Tempering

(ISO/ANSI Control; tempered as per ASTM C1048/EN12150)

Main Features & Technical Advantages

- Low Solar Heat Gain Coefficient (SHGC): High reflection of incident solar energy, improving energy savings by up to 40% in commercial buildings (according to GlassOnWeb reports).

- Corrosion & UV Resistance: Metal oxide layer forms a durable, inert barrier, vastly extending reflective glass service life up to 25–30 years.

- Spectral Selectivity: Selectively transmits visible light while rejecting IR for enhanced interior comfort and reduced A/C load.

- Color Consistency & Uniformity: Advanced CVD (chemical vapor deposition) process ensures tight tolerances & repeatability.

- Compliance: Meets or exceeds ISO 9001, ISO 12543, EN 1096, and ANSI Z97.1 standards.

Technical Specifications: 5mm Reflective Glass Dark Green

| Product Name | 5mm Reflective Glass Dark Green |

Website | Link |

| Standard Size | 1830×2440mm, 2140×3300mm, Custom |

Weight | ~12.5 kg/m² |

| Glass Thickness | 5mm |

Color | Dark Green |

| Visible Light Transmission | 20±2% |

Visible Light Reflectance | 44±2% |

| Solar Energy Transmission | 25% |

Solar Reflectance | 51% |

| Sound Insulation (Rw) | ≥30 dB |

Durability | ≥25 Years (EN 1096) |

| Fire Rating | B1/B2, per DIN 4102 |

Certification | ISO 9001, CE, CCC |

| Applications | Curtain walls, facades, windows, skylights, industrial enclosures, energy-efficient renovations |

Comparative Chart: Main Colors & Their Performance

Application Scenarios of Reflective Glass

- Commercial High-Rise Buildings: Used in façade, curtain wall, and window systems to minimize solar load, enhance aesthetics, and provide privacy.

- Industrial Plants: Protects interior surfaces from UV/solar exposure, especially for facilities in metallurgy, petrochemical, or power plants.

- Residential Buildings & Greenhouses: Improves natural lighting and thermal control, reduces UV infiltration, and lowers cooling energy needs.

- Transportation Infrastructure: Serves as glazing in subway stations, airports, rail terminals for both passive safety (tempered) and environmental control.

Case Study: Green City Mall Curtain Wall (2023)

Project: Green City Mall, Singapore

Material Used: 5mm

Dark Green Reflective Glass

Scope: 21,600m² supplied for full building envelope glazing

Results: Annual HVAC energy savings of 37% (per independent

SG Buildings Journal audit), with zero visible corrosion issues as of Q1 2024.

Client Feedback Excerpt: “The reflective glass supplied not only reduced our operating costs, but also improved indoor comfort and building appearance. Installation proved efficient, and post-sale support was reliable.”

—Project Manager, Green City Mall

Reflective Glass Market: Manufacturers & Supplier Comparison

| Company |

Country |

Major Product |

Certifications |

Lead Time (days) |

Custom Solutions |

| ZSZG Glass |

China |

5mm Dark Green Reflective Glass |

ISO 9001, EN1096, CE |

7–15 |

Yes |

| Saint-Gobain |

France |

SageBlue, Parsol Green |

ISO 9001, EN 1096 |

25–35 |

Yes |

| AGC Glass |

Japan |

Stopray, Planibel |

ISO 12543, CE, RoHS |

21–30 |

Yes |

| Şişecam |

Turkey |

EkoBlue, Bronze Reflective |

TSE, EN1096 |

18–25 |

Yes |

Customization, Logistics & Quality Assurance

- OEM & Size Customization: Custom colors, thicknesses (4–12mm), and dimensions upon request.

- Strict Packing: Edge protection, vacuum-sealed, guaranteed to minimize breakage (

- Global Delivery: 7–15 business days typical lead time, FOB or CIF terms supported worldwide.

- After-Sale Support & Warranty: 12–24 month product warranty with support teams on call; replacements or refunds for manufacturing defects covered by ISO 9001 protocol.

- Certifications: All products comply with ISO 9001, ANSI Z97.1, and local building codes.

Data Visualization: Performance of 5mm Reflective Glass (Dark Green)

Expert FAQ: Reflective Glass Technical Insights

What is the base material of reflective glass?

The base material is high-quality float glass, commonly soda-lime-silica based. Chemistry ensures high clarity, low iron, and controlled expansion for compatibility with metal oxide coatings.

What is the typical thickness range for architectural reflective glass?

Standard thicknesses are 4mm, 5mm, 6mm, 8mm, and occasionally 10mm or 12mm for high-load facades, with 5mm being the industry standard for optimal weight-strength-performance balance.

Which coating process is used for reflective glass?

Most manufacturers use Online CVD (Chemical Vapor Deposition), where metallic oxides like TiO2, Cr2O3, or SnO2 are deposited at high temperature to form a strong, weather-resistant mirror finish.

How does reflective glass meet international standards?

Renowned suppliers adhere to ISO 9001 (quality), EN 1096 (coated glass for building), ANSI Z97.1 (safety glazing), as well as regional fire ratings (DIN 4102) and performance benchmarks (ASTM C1048), ensuring universal acceptance and reliability.

What is the recommended installation standard for reflective glass?

Use of dry/wet glazing with silicone or EPDM gaskets, installed as per ASTM C1036/C1048 for glass, and EN 13830 for curtain walls. Thermal expansion joints and mechanical restraint should be considered for exterior application.

What is the lifespan and warranty policy?

Certified reflective glass, especially with CVD coatings, can provide a service life of 25+ years, with manufacturers offering up to 10 years limited warranty against discoloration, peeling, or visible defects.

What standard testing is performed before delivery?

All units tested for visible light transmittance/reflectance (per EN 410), adhesion (cross-hatch per ISO 2409), tempering (ANSI/EN), and color consistency using spectrophotometry prior to shipping.

Lead Time, Delivery & Customer Support

- Production Cycle: 3–7 days for standard sizes, 7–15 days for custom dimensions/large batches.

- Shipping: Palletized for sea freight; secure wooden crates; all shipments externally insured.

- Customer Service: 24/7 technical hotline, on-site installation support for bulk projects, and full documentation included.

- Warranty: Product replacement within 15 days of confirmed complaint; after-sales support in English/Chinese; technical documentation provided free of charge.

Conclusion & Industry References

The reflective glass sector exemplifies the fusion of material science, aesthetics, and sustainability. As reflected by industry benchmarks, technical progress in 5mm reflective glass—notably in dark green and other custom colors—delivers unmatched value in energy savings, longevity, and design flexibility.

Forum & Journal References:

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu