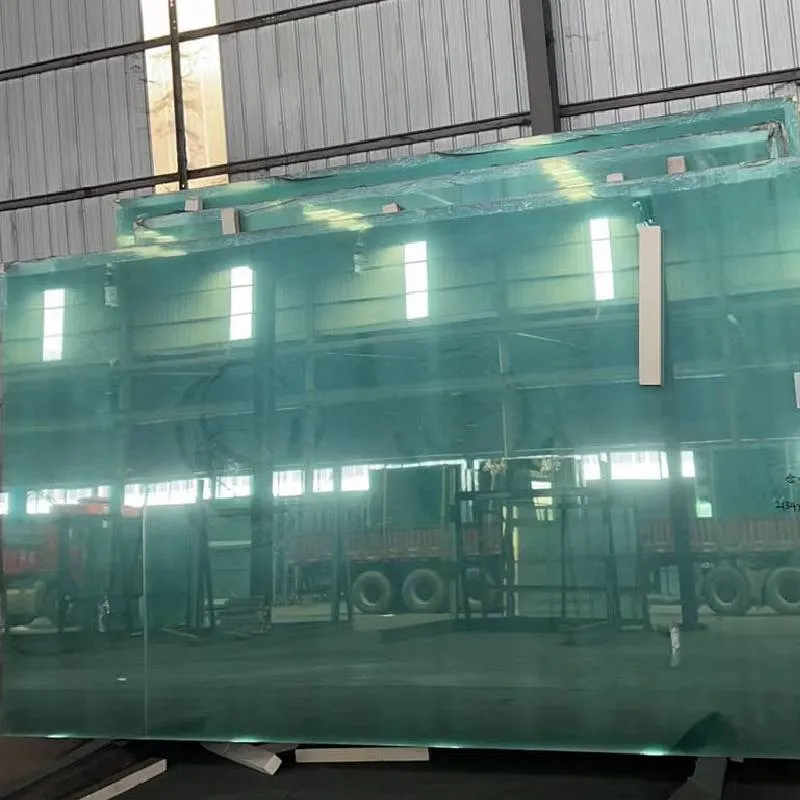

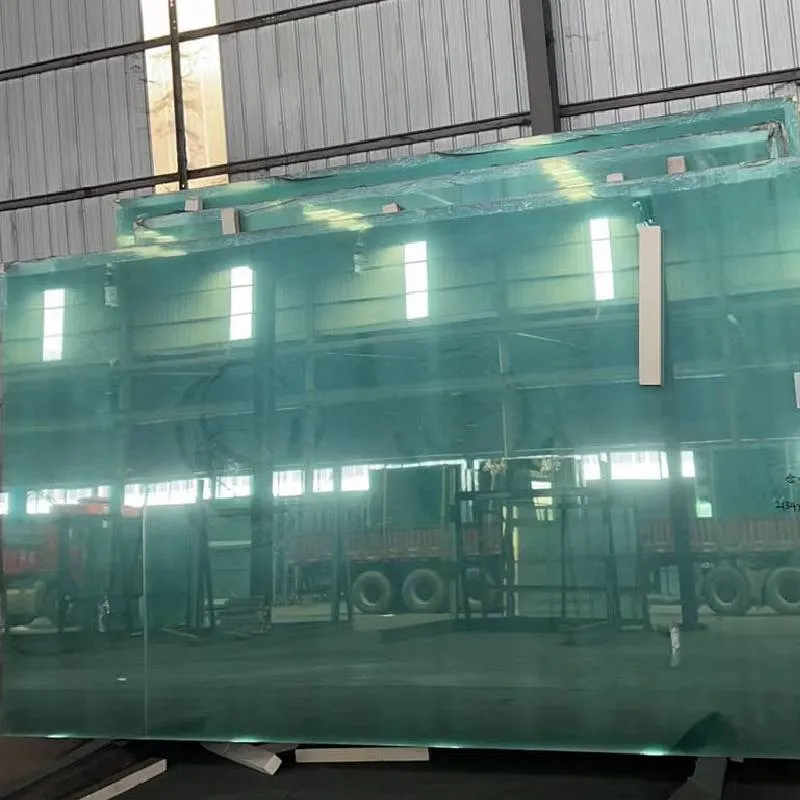

The rise of tempered glass in modern manufacturing has been nothing short of revolutionary, transforming industries ranging from automotive to consumer electronics. At the heart of this innovation are tempered glass manufacturing plants, the epicenters where state-of-the-art technology meets precise engineering. These facilities play a critical role in ensuring that tempered glass not only meets industry standards but also exceeds consumer expectations in terms of durability, safety, and aesthetic appeal.

Tempered glass, known for its strength and safety features, undergoes a specialized thermal treatment process. This process, executed within the confines of dedicated manufacturing plants, involves heating the glass to above 600 degrees Celsius and then rapidly cooling it.

The careful execution of this process puts the manufacturing plants in a pivotal position. It requires infrastructure that supports high-temperature operations, tight quality controls, and a profound understanding of material properties.

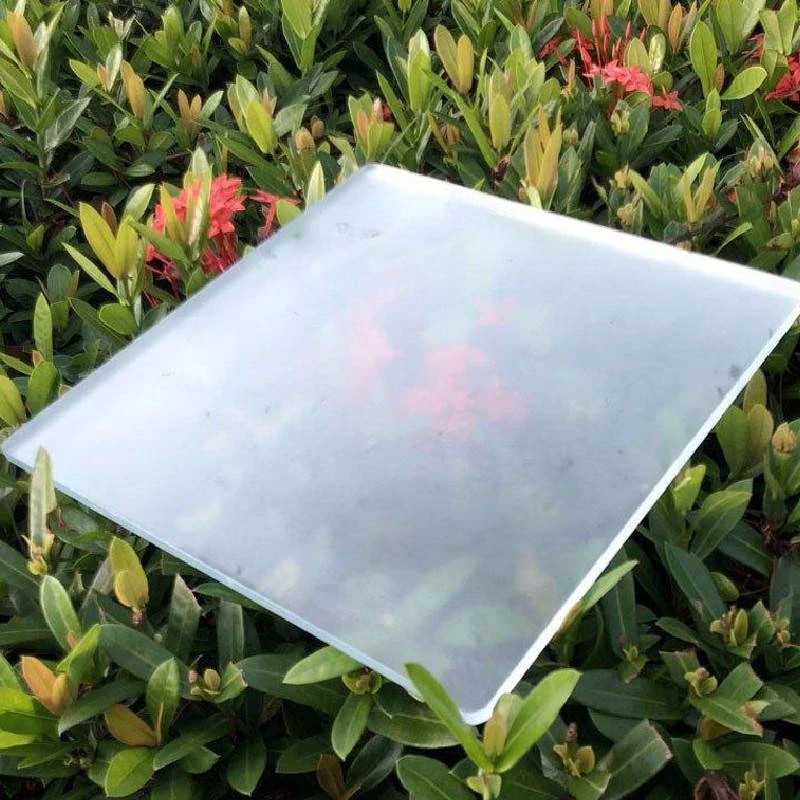

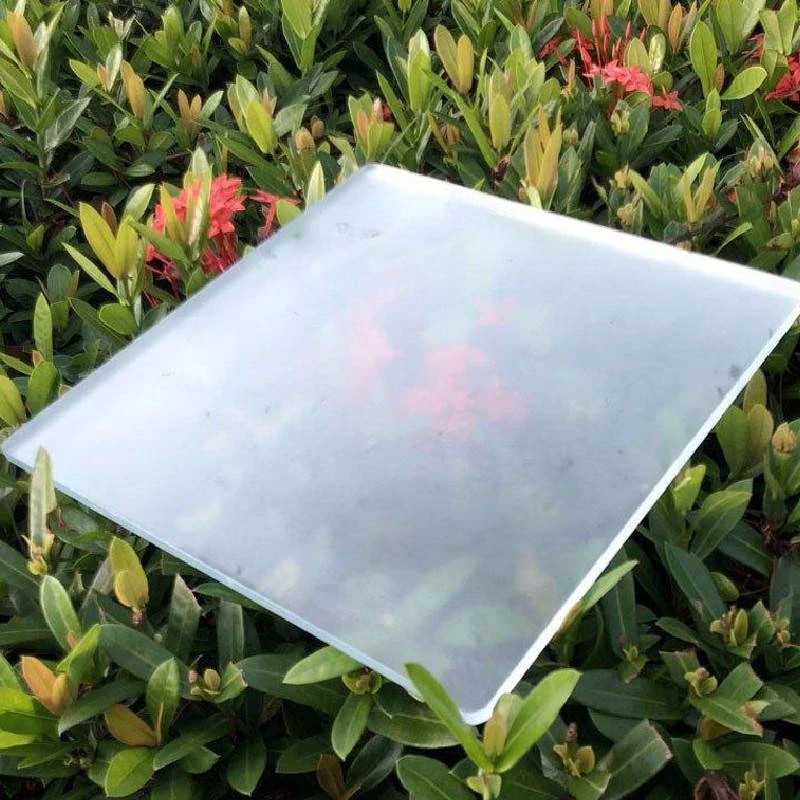

The expertise embedded in these plants cannot be overstated. Skilled technicians and engineers work alongside advanced machinery to oversee production. These professionals bring extensive knowledge of material science and engineering to the table, ensuring that every sheet of tempered glass is crafted to perfection. Their expertise allows the plants to meticulously control and tweak the tempering process depending on the glass application, whether it is for automobile windshields, protective phone screens, or architectural structures.

tempered glass manufacturing plant

Moreover, the authority these manufacturing facilities command in the industry is evident. Accredited plants often work in strict compliance with international safety and quality standards, like ISO certifications. This commitment to regulatory adherence not only ensures the safety of the products but also enhances the plant's authority and credibility. These standards facilitate a framework for innovation without compromising on quality or user safety. Esteemed manufacturing plants often invest in research and development, pushing the boundaries of what's possible with tempered glass. Their innovations might lead to the development of products that are thinner yet more durable, or even environmentally friendly glass solutions that weigh less on resources and have a longer life cycle.

Trustworthiness is a natural byproduct when manufacturing plants operate with transparency and a commitment to quality. Customers and businesses purchasing tempered glass need assurance that they are investing in a product that is not only effective but also reliable. Manufacturing plants earn this trust by maintaining an unblemished track record—every glass panel produced is a testament to precision and excellence. The best of these plants often provide detailed documentation of their processes, batch quality reports, and post-sale support services, adding layers of accountability that reinforce their trustworthiness.

In conclusion, manufacturing plants specializing in tempered glass serve as the backbone of industries reliant on this versatile material. Their role is not confined to production; they are hubs of innovation, centers of expertise, and pillars of trust in the marketplace. They blend cutting-edge technology with human skill, setting benchmarks for what tempered glass can achieve. Whether driving the future of sustainable building materials or enhancing the resilience of everyday electronics, these plants are indispensable. Their commitment to excellence cements their place as industry leaders, ensuring that tempered glass remains a material of choice for safety, durability, and beauty.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu