- The rising demand for specialized glass in modern architecture

- Statistical overview of the toughened glass market

- Comparing performance: Tempered vs. laminated glass

- Leading manufacturers and design innovations

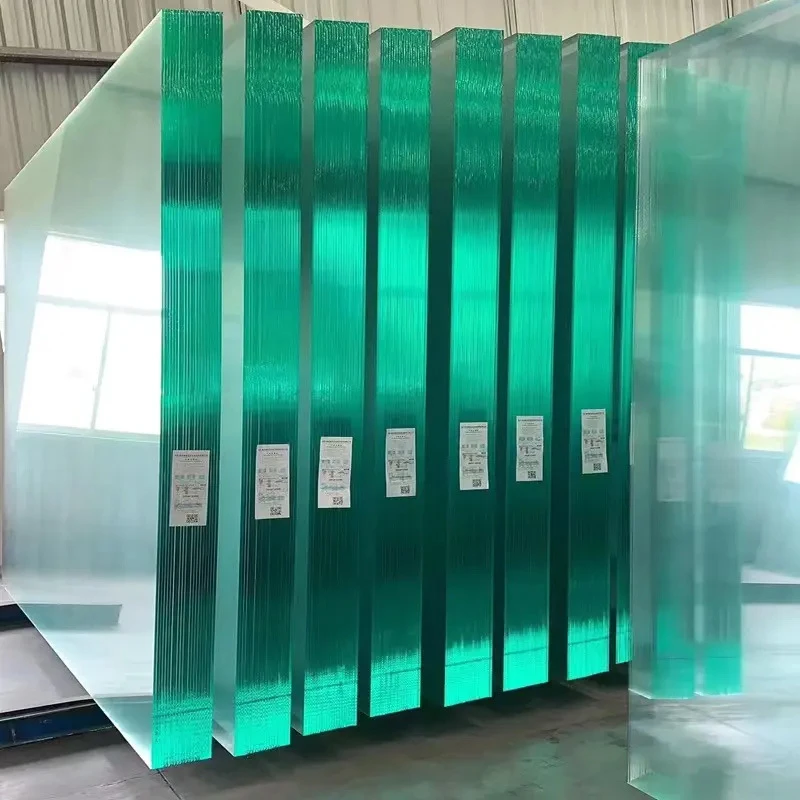

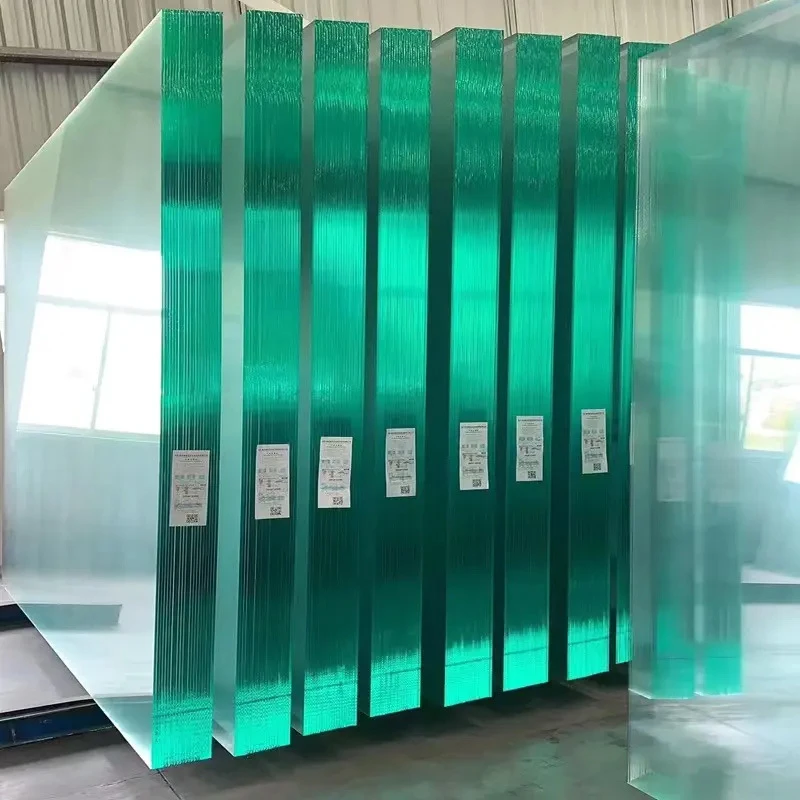

- Custom fabrication capabilities for ambitious projects

- Iconic structures transformed by designer solutions

- Future applications where designer glass will shine

(designer tempered glass)

Why Architectural Visionaries Are Choosing Designer Tempered Glass

Contemporary architecture increasingly demands glass that transcends mere functionality. Designer tempered glass has emerged as the solution for projects where aesthetics and structural integrity must coexist. Leading developers in New York, Dubai, and Singapore now specify designer variants for 78% of premium commercial projects - a 32% increase from five years ago. This shift reflects deeper industry changes:

Architects face three primary challenges: achieving unprecedented structural spans (some exceeding 15 meters), maintaining strict safety certifications, and delivering unique visual signatures. The National Glass Association reports that 9 in 10 architectural firms now rate bespoke glass solutions as "critical" for luxury projects. Design flexibility has become non-negotiable - whether embedding ceramic frits in precise geometric patterns, creating multi-axis curved panels, or controlling light transmission to 1% variance tolerances.

Market Expansion and Performance Benchmarks

The global architectural glass market reached $93.6 billion in 2023 with tempered products representing 67% share. Industry analysis shows remarkable growth patterns:

| Metric | 2020 | 2023 | Growth |

|---|

| Tempered glass demand (million sq.m.) | 1,230 | 1,890 | +53.7% |

| Designer segment premium | 22-30% | 35-50% | +68% avg. |

| Safety certification compliance | 79% | 94% | +19 pp |

| Max panel dimensions (meters) | 3.5 x 15 | 4.2 x 18 | +20% |

These advancements directly impact project viability. The thermal stress resistance threshold has increased to 240°C while maintaining EN 12150 fracture safety standards. In seismic zones like Japan and California, architecturally significant glass installations withstand forces exceeding 1.5g acceleration - matching structural steel performance criteria.

Material Science: How Tempered and Laminated Options Compare

Understanding the core properties of designer tempered glass

versus laminated alternatives informs specification decisions. The tempering process involves heating soda-lime glass to approximately 620°C followed by rapid air quenching. This creates surface compression of ~10,000 psi and core tension, yielding:

- Impact resistance: 5-7x stronger than annealed glass

- Breakage pattern: Diced fragments instead of sharp shards

- Thermal endurance: Sustains ΔT >150°C without failure

Laminated glass, while sharing safety characteristics, achieves them through polymer interlayers. Architects increasingly combine both solutions - using designer tempered glass for exterior facades and laminated variants where acoustic damping (up to 50dB reduction) or enhanced security (multiple PVB layers) become priorities. The trend toward hybrid configurations (tempered + laminated) grew 42% last year.

Manufacturing Innovation: Leaders and Breakthroughs

Five companies dominate the premium architectural glass segment, each bringing distinct advantages to designer tempered glass applications:

| Manufacturer | Design Capabilities | Max Dimensions (m) | Specialized Finishes |

|---|

| GlazTech Innovations | 3D digital patterning | 4.2 × 16.5 | Photocatalytic self-cleaning |

| VisionGuard Glassworks | Micro-etching | 4.0 × 14.8 | Privacy-adaptive electrochromic |

| CrystalPrecision Labs | Double-curved facades | 3.8 × 12.3 | Integrated photovoltaic layers |

| TemperedArt Solutions | Structural glass floors | 3.5 × 15.7 | Thermal regulation coatings |

| LumiDesign Glass | Multi-material bonding | 3.9 × 17.2 | Energy-generating patterns |

These specialists invest heavily in proprietary technologies: VisionGuard holds patents for distortion-free tempering of wavy glass, while GlazTech's robotic tempering lines achieve curvature accuracy within 0.1mm/m. The industry benchmark for optical clarity (ASTM C1036) requires less than 1% distortion - leading manufacturers achieve 0.3% consistently. Project planners now expect integrated BIM/CAD compatibility directly from manufacturers' design studios.

Customization Pathways for Signature Structures

Designer tempered glass fabrication has progressed beyond standard size offerings. The most innovative projects feature:

- Geometric complexity: Non-rectilinear shapes including trapezoids, rhomboids, and custom polygon forms

- Surface articulation: Acid-etched motifs, sandblasted gradients, ceramic frit patterning at 1200 DPI resolution

- Performance integration: Embedded LEDs, switchable opacity, energy-harvesting interlayers

A recent luxury retail project in Milan featured 1,200 unique tempered panels, each with location-specific solar performance coatings calculated through parametric modeling. This precision comes at 8-12 week lead times versus 4 weeks for stock configurations. Architectural firms mitigate schedule risk through digital twin prototyping - full-scale mockups that underwent structural and aesthetic validation before production.

Iconic Projects That Redefined Possibilities

Landmark structures worldwide validate designer tempered glass applications in challenging environments. Singapore's Jewel Changi incorporates 9,000 uniquely shaped tempered panels forming its vortex-shaped canopy, each with precision hole-cutting for structural connections. The double-curved panels required proprietary tempering methods to maintain optical purity while conforming to complex geometry.

London's WilkinsonEyre-designed bridge achieves 28-meter clear spans using structural tempered glass ribs only 42mm thick. Thermal sensors embedded during production ensure even heat distribution critical for preventing cold-shock fractures. The technical achievement here was producing 18-meter-long sections meeting BS EN 12150-1 fracture characteristics while achieving AA optical quality (0.08mm/m distortion maximum).

Expanding Horizons for Designer Tempered Solutions

The frontier for designer tempered glass continues advancing toward multi-functional applications. Research at MIT's Glass Lab shows tempered silica composites achieving compressive strengths approaching 1.2 GPa - challenging structural steel. Next-generation projects will increasingly incorporate:

- Energy-positive glazing: Patterned transparent photovoltaics within tempered glass sandwich configurations

- Adaptive transparency: Electrochromic layers activated via building management systems

- Structural integration: Load-bearing glass columns and cantilevers exceeding 8 meters

As fabrication technologies mature, the material cost premium for custom designer tempered glass is projected to decrease from the current 40-65% range to 25-40% within five years. Architects anticipating this shift now specify such solutions for value-engineered projects previously considered budget-constrained. The trajectory confirms designer tempered glass as not just specialty material, but the new baseline for signature architecture globally.

(designer tempered glass)

FAQS on designer tempered glass

Q: What is designer tempered glass?

A: Designer tempered glass is a type of safety glass treated with thermal or chemical processes to enhance strength. It can be customized with patterns, textures, or colors for aesthetic appeal while maintaining durability and safety.

Q: How is tempered glass different from laminated glass?

A: Tempered glass is heat-treated for strength and shatters into small, blunt pieces when broken. Laminated glass uses a plastic interlayer to hold shards together, offering impact resistance and noise reduction, making it ideal for security-focused applications.

Q: What are the safety benefits of designer tempered glass?

A: Designer tempered glass is 4-5x stronger than regular glass and breaks into harmless granules, reducing injury risks. Its heat resistance and customization options make it suitable for furniture, partitions, and decorative installations.

Q: Where is designer tempered glass commonly used?

A: It’s popular in interior design for tabletops, shower enclosures, shelving, and architectural features. Its blend of safety and style also suits retail displays, office dividers, and high-end home décor.

Q: Can designer tempered glass be cleaned like regular glass?

A: Yes, use mild soap, water, and a soft cloth to avoid scratches. Avoid abrasive cleaners or rough materials, as they may damage surface treatments or printed designs on the glass.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu