The Production of Tempered Glass A Comprehensive Overview

Tempered glass, also known as toughened glass, is a type of safety glass that has been treated to withstand impact and thermal stress. Its unique properties make it a popular choice for applications ranging from car windows to shower doors, and even glass facades in modern architecture. The production of tempered glass involves several steps, each crucial to achieving the strength and durability that the material is renowned for.

1. Raw Material Preparation

The first step in the production of tempered glass is the selection and preparation of raw materials. Typically, the primary component of tempered glass is silica sand, which is mixed with other materials such as soda ash and limestone. These components are carefully measured and thoroughly mixed to create a homogeneous batch. The quality of the raw materials is critical, as impurities can greatly affect the final product’s properties.

2. Melting Process

Once the raw materials are prepared, the mixture is fed into a furnace where it is heated to temperatures exceeding 1500 degrees Celsius (2732 degrees Fahrenheit). This melting process transforms the solid materials into a liquid glass. The furnace must maintain consistent heat throughout to ensure even melting, and it requires a carefully controlled environment to prevent contamination and defects in the glass.

3. Forming the Glass

After the raw materials have melted, the liquid glass is poured into molds or floated on a bed of molten tin to create flat glass sheets—a method known as the float glass process. The thickness of the glass can be controlled during this stage, and glass sheets can vary from a few millimeters to several centimeters in thickness, depending on their intended application.

4. Annealing

Following the forming process, the glass sheets undergo an annealing stage. In this step, the sheets are slowly cooled in a controlled environment, which relieves internal stresses that could lead to fractures. The annealing process is critical; if not done properly, the glass could remain brittle and susceptible to breakage.

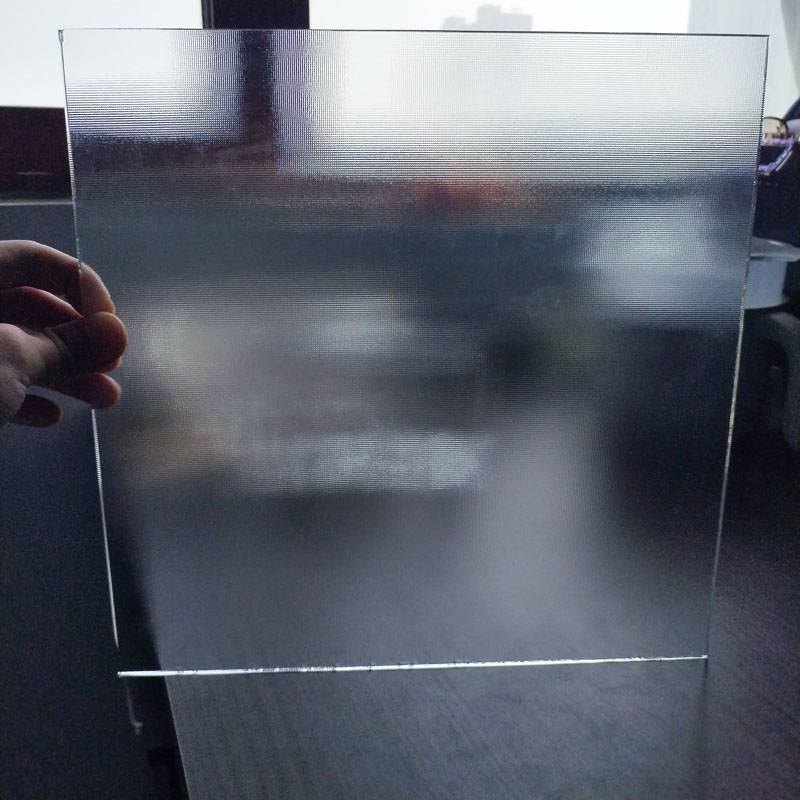

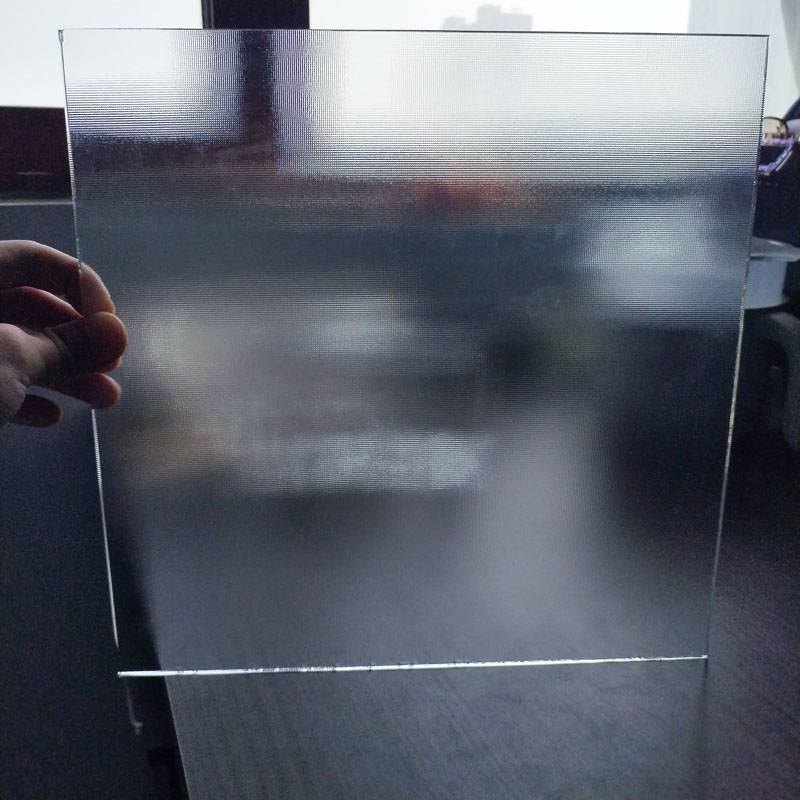

tempered glass production

5. Cutting and Edge Processing

Once the glass has been properly annealed and cooled, it can be cut to size according to the specifications of customers or designers. The edges of the glass are often finished through processes such as grinding and polishing to ensure they are smooth and safe to handle. This step is vital not only for aesthetics but also for safety, as sharp edges can pose significant risks.

6. Tempering

The defining step in the production of tempered glass is the tempering process itself. The glass sheets are reheated to a temperature between 600 and 700 degrees Celsius (1112 to 1292 degrees Fahrenheit) in a tempering oven. Once they reach this temperature, the glass is rapidly cooled using air jets—a process known as quenching. This rapid cooling creates a surface compression and enhances the strength of the glass, making it up to five times stronger than standard untempered glass.

7. Quality Control

Quality control is an integral part of the tempered glass production process. Throughout each production stage, inspectors monitor various parameters such as thickness, optical clarity, and stress levels. Advanced technologies such as optical inspection systems are often employed to detect any imperfections. This vigilance ensures that only high-quality tempered glass reaches the market.

8. Application and Benefits

Tempered glass is celebrated for its strength, safety, and thermal resistance. When broken, it shatters into small, blunt pieces that are less likely to cause injury, making it ideal for safety applications. Additionally, its ability to withstand sudden temperature changes makes it suitable for use in environments where heat resistance is crucial, such as in kitchen appliances and exterior windows.

In conclusion, the production of tempered glass is a detailed and intricate process that combines science and artistry. From raw material selection to final inspection, each phase plays a pivotal role in ensuring that the end product is not only durable but also safe and visually appealing. As demand for high-performance materials continues to rise, tempered glass will undoubtedly remain at the forefront of innovation in the manufacturing industry.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu