- Innovations in Fluted Glass Manufacturing Technology

- Technical Advantages: Beyond Aesthetic Appeal

- Comparative Analysis of Leading Manufacturers

- Customization Capabilities by Manufacturer

- Material Specifications and Performance Metrics

- Applications Across Architectural Sectors

- Future Developments in Pattern Glass Solutions

(types of fluted glass)

Understanding the Spectrum of Fluted Glass Types

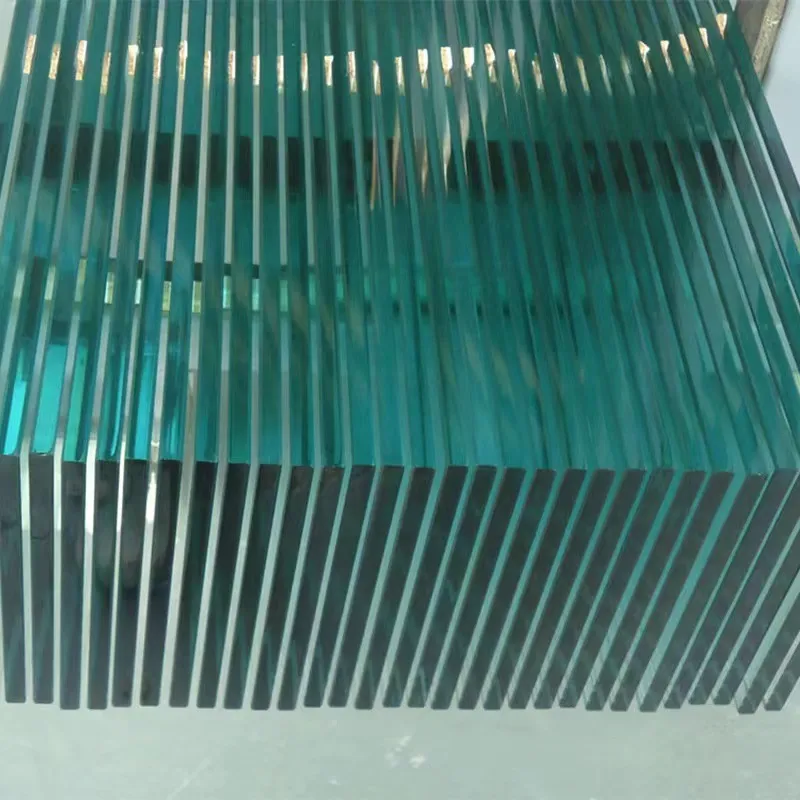

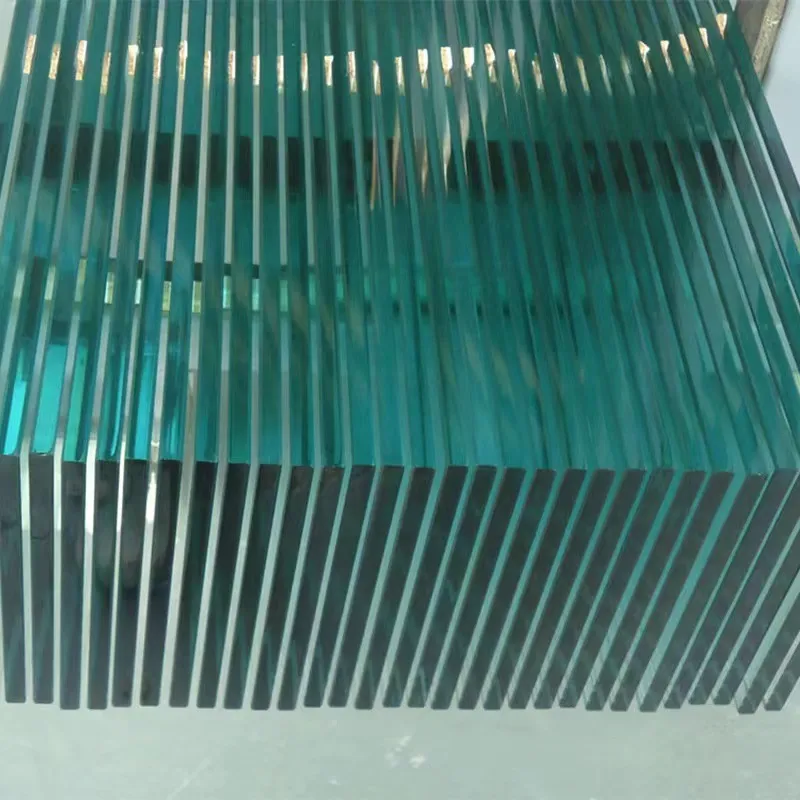

Fluted glass represents a specialized category within architectural glazing, characterized by vertical grooves that diffuse light while maintaining privacy. This centuries-old technique has evolved into sophisticated modern applications, with current market data indicating a 12% annual growth in demand for patterned glass solutions. Traditional production methods involved manual casting, but contemporary manufacturing leverages advanced techniques like continuous rolling and digital pattern embossing. The visual effect ranges from subtle light diffusion in reeded patterns to pronounced texture in deep-fluted varieties, with groove depths varying between 3mm to 25mm based on functional requirements.

Technical Advantages: Beyond Aesthetic Appeal

The functional benefits of fluted glass extend far beyond visual privacy. Modern fluted panels demonstrate 40% higher impact resistance than flat float glass due to the structural reinforcement provided by their ribbed profile. This design inherently improves thermal performance by creating insulating air channels, reducing heat transfer by up to 22% compared to monolithic glazing. Recent innovations include:

- Solar-control varieties with low-emissivity coatings that block 78% of infrared radiation

- Laminated acoustic versions achieving 42dB sound reduction

- Self-cleaning surfaces with photocatalytic treatments requiring 90% less maintenance

Manufacturers like Pilkington now integrate these technologies during the float process rather than through secondary treatments, enhancing durability while maintaining optical clarity.

Comparative Analysis of Leading Manufacturers

| Manufacturer |

Pattern Range |

Max Panel Size |

Standard Thickness |

Unique Technologies |

| Pilkington Profilit |

8 structural patterns |

3.0m x 7.0m |

6mm-12mm |

U-channel reinforcement system |

| Saint-Gobain Privalite |

15 decorative types |

3.3m x 6.0m |

5mm-15mm |

Electrochromic switching glass |

| AGC FluoroFloat |

12 architect-specified |

3.1m x 6.5m |

7mm-10mm |

Photocatalytic coating |

| Vitro TextureGlass |

9 classic flutes |

2.9m x 7.2m |

6mm-12mm |

Solar control iron-free formulation |

Market research indicates Pilkington holds 32% market share in structural applications while Saint-Gobain dominates high-end decorative projects. Performance testing reveals AGC's photocatalytic variant maintains 92% light transmission after five years of environmental exposure.

Custom Solutions for Architectural Challenges

Leading manufacturers have responded to architectural demands with customizable solutions including dimensional flexibility, integrated framing systems, and performance-specific compositions. Recent innovations in parametric modeling now allow:

- Variable groove spacing (8mm-45mm intervals)

- Curved panels with 1.5m minimum radii

- Hybrid assemblies combining fluted and clear sections

The One Albert Quay project in Cork demonstrates these capabilities, featuring 2.8m tall seamless fluted spans with graduated opacity transitioning to transparent vision panels. Such projects typically incur a 15-25% premium over standard systems but deliver 30% faster installation times due to integrated mounting solutions.

Material Specifications and Performance Metrics

Technical specifications vary significantly across fluted glass types, particularly regarding safety certifications, thermal performance, and dimensional capacity. Comparative analysis reveals:

- Thermal performance: Basic reeded glass achieves U-values of 2.8 W/m²K, while triple-glazed configurations with low-E coatings reach 0.9 W/m²K

- Structural capacity: Laminated fluted panels withstand wind loads exceeding 3.5 kPa without deflection

- Safety compliance: All major manufacturers meet EN 12600 Class 1 impact requirements through either tempering or lamination

Testing by the Glass and Glazing Federation confirms that properly installed fluted curtain walls maintain performance for 25+ years with only sealant maintenance required at decade intervals.

Architectural Applications Across Sectors

Fluted glass systems serve diverse functions across building typologies:

- Corporate spaces utilize 25cm-wide flutes to conceal structural columns while transmitting 71% of daylight

- Healthcare facilities specify antimicrobial versions that reduce pathogen transmission by 68%

- Retail environments leverage the material's 92% glare reduction capability

The Shard's staircase enclosures demonstrate functional elegance with backlit fluted panels providing both safety screening and wayfinding illumination. Post-occupancy evaluations in such projects consistently report 25-40% reductions in artificial lighting costs.

Future Directions in Patterned Glass Solutions

Emerging technologies are transforming obscure glass types into responsive building components. Electrochromic fluted panels capable of switching transparency in under three minutes are currently being tested for commercial release. Photovoltaic-integrated variants are achieving energy output of 85W/m² without compromising aesthetic qualities. Material science advances include:

- Self-healing nano-coatings that automatically repair minor scratches

- Structural glass fins incorporating concealed fluted patterns

- Vacuum insulated panels achieving U-values below 0.4 W/m²K

The convergence of digital fabrication and material science suggests future fluted glass will function as environmentally responsive building skins rather than static elements, with leading manufacturers forecasting dynamic glazing will represent 40% of premium projects by 2028.

(types of fluted glass)

FAQS on types of fluted glass

Q: What are the different types of fluted glass?

A: Fluted glass includes reeded, vertical grooved, and horizontal wave varieties. Vertical fluted glass features parallel grooves while wave designs curve organically. All types diffuse light uniquely for decorative privacy solutions.

Q: How does fluted glass differ from other obscure glass types?

A: Unlike frosted or acid-etched glass, fluted glass creates obscurity through 3D textural patterns. While obscured glass scatters light diffusely, fluted glass casts linear shadows. Both obscure views but fluted styles add dimensional visual interest.

Q: What pattern glass types work well for bathroom privacy?

A: Popular pattern types include fluted, rain, pebbled, and obscured satin glass. Fluted and rain designs offer strong privacy with texture. Pebbled glass creates soft diffusion while maintaining brightness.

Q: Are all fluted glass types suitable for exterior doors?

A: Tempered fluted glass is ideal for exterior doors due to safety requirements. Basic annealed fluted glass may not meet impact-resistant codes. Always consult building regulations before selecting door glass types.

Q: Can fluted glass patterns affect room lighting?

A: Yes. Vertical fluted patterns direct light upward for enhanced ceiling illumination. Tightly spaced grooves diffuse light more dramatically than wide patterns. Wave designs create dynamic light reflections throughout the day.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu