Float glass manufacturing represents a pinnacle of innovation in the glass production industry, offering unparalleled quality and efficiency. As a process, it combines both art and science, leading to the production of excellent glass sheets for diverse applications such as architectural glazing, automotive windows, and solar panels. This method not only demonstrates extraordinary expertise by leveraging advanced technology but also underscores a deep-rooted trust and authority built over decades.

Floating glass begins with raw materials such as silica sand, soda ash, dolomite, limestone, and salt cake. These components are meticulously measured, ensuring a precise mix that will ultimately determine the glass's quality. Experienced professionals oversee this blend, drawing from a wealth of historical data and modern analytics. This juncture marks the intersection of traditional knowledge and cutting-edge innovation – a synergy that guarantees a reliable and high-quality product.

The mixture is then introduced to a furnace where it's subjected to temperatures exceeding 1,500 degrees Celsius. At this high heat, the materials melt into a molten glass ribbon. This stage demands acute attention and expertise, as even minute errors in temperature control can lead to imperfections in the glass.

Mastery in managing these variables is a testament to the authority float glass manufacturers hold within the industry.

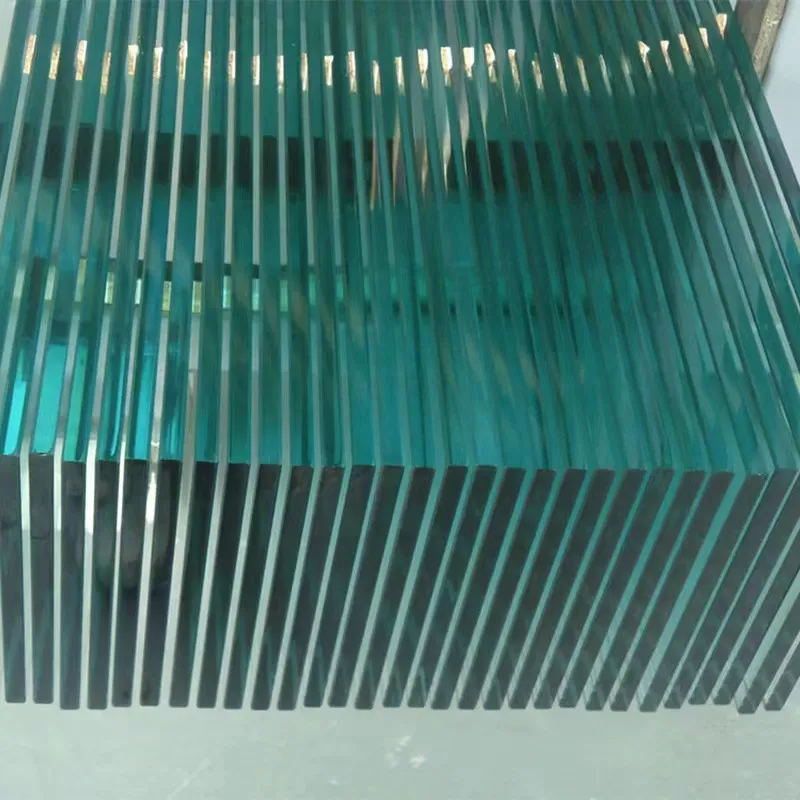

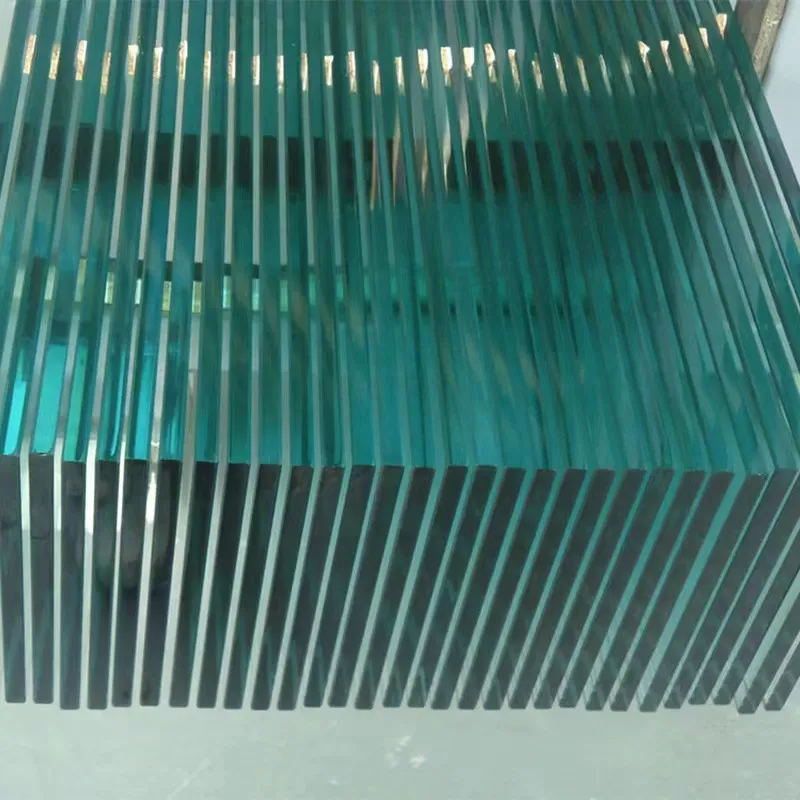

Once molten, the glass is carefully guided onto a bath of molten tin. Due to surface tension and gravity, the glass ‘floats’ across the tin, forming a flat and uniform sheet free from distortions and ripples. This process exemplifies the credibility manufacturers have earned, as they leverage physics principles to achieve consistency – a vital attribute for products expected to meet high design and safety specifications.

As the glass progresses through the bath, it begins to cool and solidify, entering a controlled annealing process known as a lehr. During this stage, the glass is subjected to a controlled cooling that relieves internal stresses. This is crucial for maintaining the glass's strength and transparency. The expertise involved here not only lies in optimizing this cooling curve but also in ensuring each batch of glass exceeds industrial standards.

float glass manufacturing

The finished float glass is then rigorously tested against international quality standards. These stringent tests verify the glass's thickness, optical clarity, durability, and overall finish. Such thorough scrutiny reflects the industry's commitment to trustworthiness and reliability. Manufacturers continue to refine these testing protocols, keeping them abreast with the rising demands and expectations from global markets.

Stakeholders in the float glass manufacturing arena – from raw material suppliers to engineers and quality assurance specialists – consistently pursue innovation and precision. Their collective experience drives the industry's evolution, paving the way for sustainable practices. Environmental considerations motivate a shift towards reduced emissions and resource-efficient manufacturing, further solidifying the long-term dependability of float glass.

Adopting float glass in products delivers unmatched quality and performance. Its flawless surface and structural integrity make it preferred for high-end architectural projects and environmentally conscious constructions. Automotive and electronics sectors also benefit from its robustness and versatile capabilities, underscoring the industry's authoritative position in transforming raw elements into engineered wonders.

In conclusion, the float glass manufacturing industry stands as a beacon of Experience, Expertise, Authoritativeness, and Trustworthiness. Through continuous innovation, impeccable craftsmanship, and a commitment to sustainable practices, it remains a crucial component of modern technological and architectural advancements. For stakeholders looking to invest or collaborate within this domain, float glass manufacturing offer a wealth of opportunities driven by a legacy of excellence and a future of boundless potential.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu