Float Glass Production A Comprehensive Overview

Float glass, a type of glass widely used in architecture, automotive, and interior design, is produced through a highly refined method known as float glass production. This innovative process has revolutionized the glass manufacturing industry, enabling the creation of high-quality, smooth, and perfectly flat glass sheets. Understanding the floating glass production process, its applications, and environmental implications is essential for appreciating its significance in modern construction and design.

The Float Glass Process

The float glass manufacturing process was developed in the mid-20th century and involves several key steps. The primary ingredients used in float glass production are silica sand, soda ash, and limestone, along with various additives for color and other properties. The process begins with the mixing of these raw materials, which are then heated in a furnace at extremely high temperatures, typically around 1700 degrees Celsius.

Once molten, the glass is poured onto a bed of molten tin in a continuous flow system. The tin is carefully selected due to its properties, which allow it to maintain a flat surface while remaining liquid. As the molten glass floats on the tin, it spreads out and forms a uniform sheet. The thickness of the glass can be controlled by adjusting the amount of molten glass poured onto the tin. This method not only ensures a smooth surface but also results in glass sheets of uniform thickness and composition.

After forming, the glass cools gently in an annealing lehr, where it is gradually brought down to room temperature. This slow cooling process relieves any internal stresses that may have formed during production. Finally, the glass sheets are cut to size and dispatched for further processing or direct use in various applications.

Applications of Float Glass

Float glass is highly versatile and finds applications across multiple industries. In architecture, it is a primary material for windows, facades, and curtain walls, offering light transmission and thermal insulation. Due to its clarity and strength, it is also used in glass doors, skylights, and glass partitions in hotels and commercial buildings. In residential design, float glass is used for mirrors, shower enclosures, and table tops, combining aesthetic appeal with functionality.

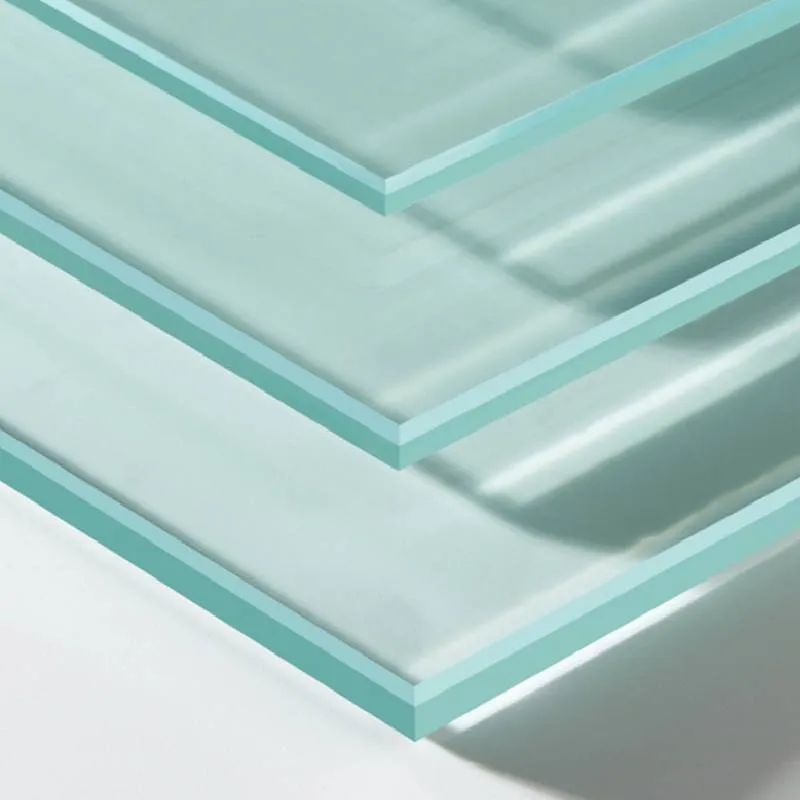

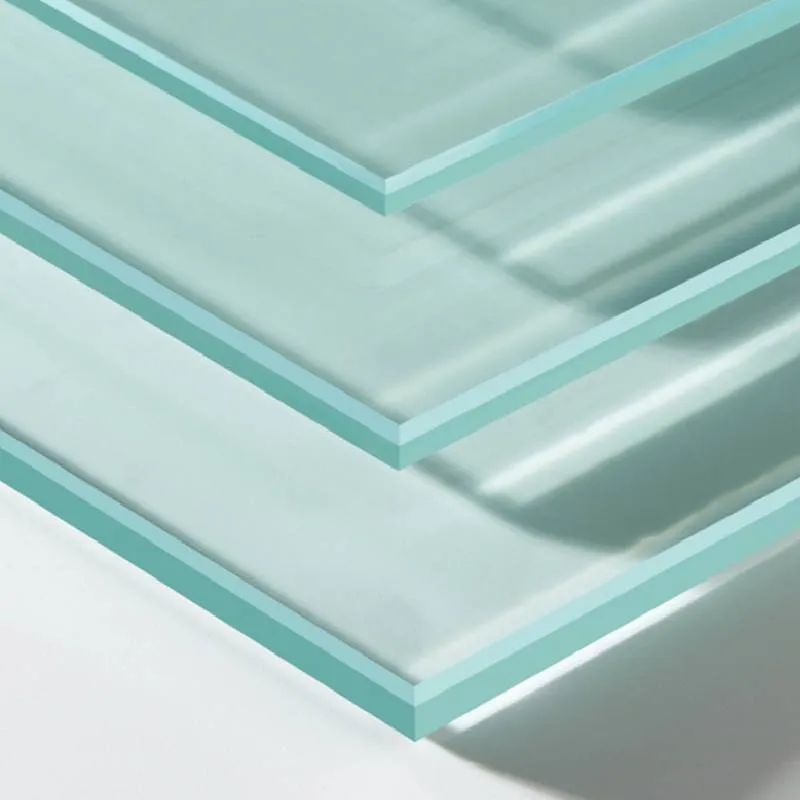

float glass production

The automotive industry relies on float glass for windshields, side windows, and rear windows. The ability to produce large, flawless sheets of glass is crucial for the increasing demand for modern vehicle designs that emphasize safety and visibility. Additionally, float glass plays a critical role in the manufacturing of glass containers and electronics, highlighting its importance in everyday life.

Environmental Considerations

While float glass production is highly efficient, it is not without environmental concerns. The energy-intensive nature of the process, particularly the melting of raw materials at high temperatures, results in significant energy consumption and greenhouse gas emissions. As the world increasingly shifts towards sustainability, the glass manufacturing industry is exploring ways to mitigate its environmental impact.

One approach is the recycling of glass, which significantly reduces the energy needed for production. Recycled glass can replace a portion of raw materials in the manufacturing process, conserving resources and lowering emissions. Additionally, advancements in technology and the use of alternative energy sources, such as solar or wind power, are being leveraged to make float glass production more sustainable.

Moreover, using energy-efficient furnaces and optimizing production processes can further reduce the carbon footprint of glass manufacturing. As consumers and industries prioritize sustainability, manufacturers are adopting greener practices to respond to market demands.

Conclusion

Float glass production is a sophisticated process that significantly contributes to various sectors, from construction to automotive. Its unique properties, derived from the float process, allow for unparalleled clarity and durability. However, the industry must continuously adapt to environmental challenges by implementing sustainable practices. As innovations in technology and recycling methods develop, float glass production can continue to thrive while minimizing its impact on the planet, ensuring its relevance in a sustainable future. The journey of float glass from raw materials to a finished product encapsulates not only craftsmanship but also the importance of responsible manufacturing in the modern age.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu