Sheet glass manufacturing is a fundamental process in the production of glass used for a variety of applications, including windows, mirrors, and glass doors. This industry is characterized by its sophisticated technology and strict quality control measures to meet the increasing demands of modern architecture and design.

The manufacturing of sheet glass generally involves several key processes melting, forming, annealing, and polishing. The journey begins with raw materials, primarily silica sand, soda ash, and limestone, which are combined in a furnace. This mixture is heated to temperatures exceeding 1,400 degrees Celsius to form molten glass. The high temperature ensures that the raw materials fully melt and fuse together, creating a homogenous liquid glass suitable for further processing.

Once the molten glass is prepared, it is formed into sheets using one of several techniques. The most commonly used method is the float glass process, which involves pouring molten glass onto a bed of molten tin. This creates a smooth, flat surface as the glass spreads out and floats on the tin. The float method not only produces glass with high optical clarity but also allows for uniform thickness, which is crucial for applications like windows.

After the glass is formed, it undergoes a cooling process known as annealing. This step involves gradually lowering the temperature of the glass in a controlled environment, which relieves internal stresses that may have developed during the forming process. This is done in a lehr, a long furnace that maintains a consistent temperature gradient. Proper annealing is essential, as it ensures the durability and strength of the final product.

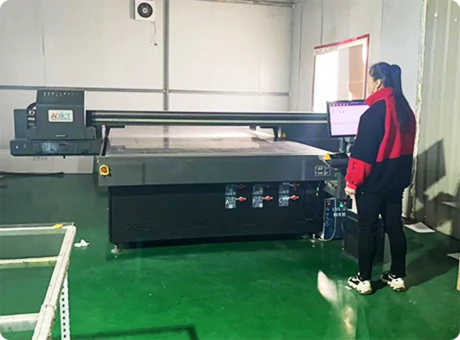

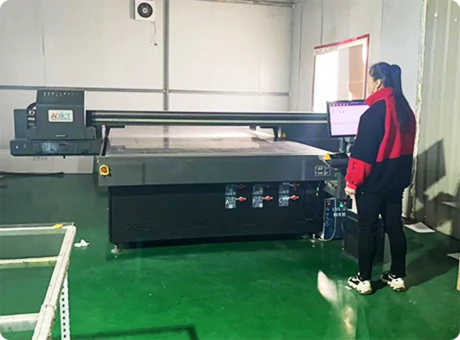

sheet glass manufacturing

Once cooled, the glass sheets are cut to size and undergo finishing processes, including polishing and surface treatments. Polishing is crucial as it enhances the clarity and smoothness of the glass, making it suitable for high-end applications. Additionally, surface treatments such as coating and laminating can be applied to improve energy efficiency, UV protection, or safety features, such as shatter resistance.

Sustainability has become a critical focus in sheet glass manufacturing. The industry is exploring ways to reduce energy consumption, minimize waste, and utilize recycled materials. For instance, manufacturers can incorporate cullet, or recycled glass, into their production process. This not only reduces the overall carbon footprint but also lowers energy requirements, as cullet melts at a lower temperature than raw materials.

The demand for high-quality sheet glass is continuously on the rise due to trends in architecture and interior design that favor larger glass surfaces and innovative applications. Modern buildings often incorporate extensive glazing for aesthetic reasons and energy efficiency. This has led to advancements in glass technology, including tempered and laminated glass, which offer enhanced strength and safety benefits.

In conclusion, sheet glass manufacturing is a complex process that integrates advanced technology and sustainability practices. From the careful selection of raw materials to the final finishing touches, each step contributes to producing high-quality glass that meets the needs of contemporary society. As the industry continues to evolve, innovations in manufacturing processes and a commitment to environmental responsibility will shape the future of sheet glass production.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu