The Art and Science of Making Tempered Glass

Tempered glass, also known as toughened glass, is a type of safety glass that is processed by controlled thermal gradients to increase its strength compared to normal glass. This kind of glass is widely used in various applications, such as in buildings, cars, and consumer electronics, due to its enhanced durability and safety features. The process of making tempered glass combines both art and science, requiring precision, knowledge, and the right technology.

The first step in manufacturing tempered glass involves selecting the right raw materials, typically silica sand, soda ash, and limestone. The quality of the raw materials significantly influences the final product. Once the ingredients are acquired, they are mixed and heated in a furnace to form molten glass. This is where the magical transformation begins. The melting process requires carefully controlled temperatures to ensure even melting and to eliminate any bubbles that might weaken the structure of the glass.

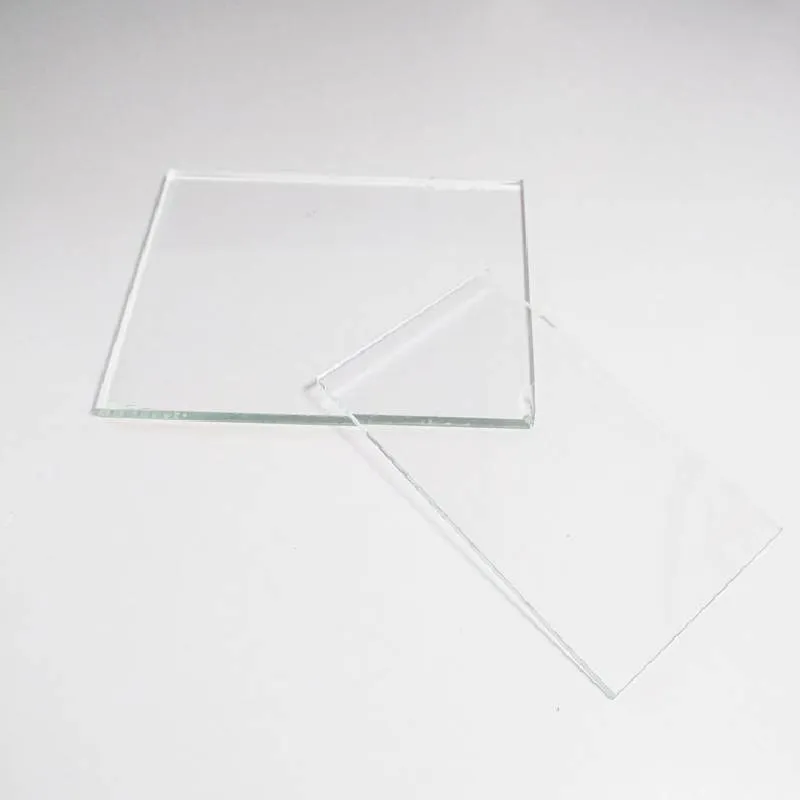

After melting, the molten glass is formed into sheets using various techniques, such as float, casting, or pressing. The float glass method, which involves pouring molten glass onto a bed of molten tin, is the most common due to its ability to produce perfectly flat sheets. Once the glass is formed, it is cooled down slowly in a process called annealing, which relieves internal stresses and ensures uniform thickness.

making tempered glass

The real transformation occurs when the glass is ready to be tempered. The tempered glass-making process includes heating the glass sheets to temperatures reaching up to 620 degrees Celsius (approximately 1,150 degrees Fahrenheit). This high-temperature treatment is crucial because it alters the physical properties of the glass. After reaching the desired temperature, the glass is rapidly cooled using jets of cold air in a process known as quenching. This rapid cooling creates a compressive stress on the surface of the glass while allowing internal tensile stress to develop. As a result, tempered glass becomes much stronger than standard glass, with the ability to withstand greater impact and thermal stress.

In terms of safety, tempered glass shatters into small, blunt pieces rather than sharp shards. This feature minimizes the risk of injury from broken glass, making it an ideal choice for applications such as shower doors, glass doors, and tables. Additionally, tempered glass can endure high temperatures, making it suitable for use in kitchen appliances and buildings exposed to thermal changes.

Overall, the process of making tempered glass exemplifies the intersection of art and science. While the technology and methods involved require a high level of expertise, the aesthetic appeal of glass products remains salient. The clarity and brilliance of tempered glass make it an attractive choice for architects and designers, who value both functionality and beauty.

In conclusion, tempered glass is more than just a material; it is a testament to human ingenuity in combining rigorous scientific principles with creative design. Its strength, safety, and versatility have made it an essential component in modern architecture and everyday items, enhancing the quality and safety of our lives. As technology advances, the future of tempered glass promises even more innovations, paving the way for new applications and improved materials.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu