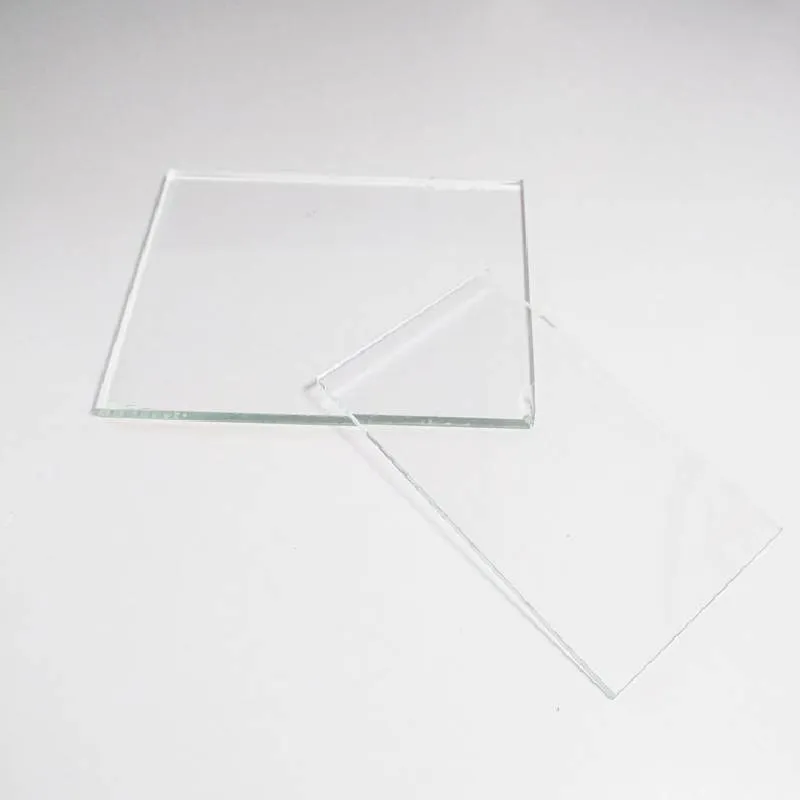

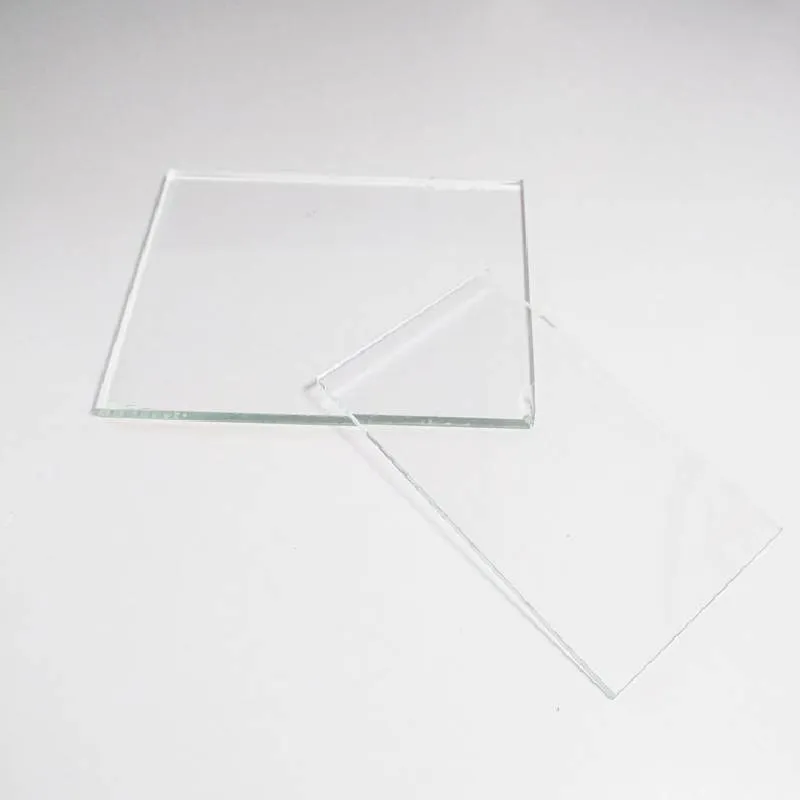

Float glass, a fundamental element in modern architecture and design, has revolutionized the construction industry with its versatility and efficiency. Its creation process involves floating molten glass on a bed of molten metal, typically tin, which allows for the production of large, flawless sheets of glass. This method, pioneered by Sir Alastair Pilkington in the 1950s, has set a new standard for glass manufacturing globally, ensuring consistency in thickness and clarity.

Incorporating float glass into architectural projects offers numerous benefits due to its superior optical clarity and uniformity. Architects and designers favor it for high visibility installations such as windows, partitions, and curtain walls, where both appearance and performance are crucial. Its ability to be produced in various thicknesses meets diverse safety and design requirements, making it an ideal choice for projects ranging from residential to commercial buildings.

Safety and sustainability have become paramount considerations in the construction industry, and float glass addresses these concerns effectively. It can be tempered or laminated to enhance impact resistance, aligning with safety regulations and providing peace of mind in environments where glass breakage could pose significant hazards. Additionally, the recyclability of float glass contributes to sustainable building practices, as it can be reprocessed multiple times without loss of quality, thus supporting circular economy principles.

The scientific expertise behind float glass technology is continually evolving, leading to innovative enhancements such as low-emissivity (low-E) coatings. These coatings improve energy efficiency by reflecting ultraviolet and infrared light, reducing both heating and cooling costs while maintaining high levels of natural light. The professional application of these coatings requires a deep understanding of building orientation and climate, ensuring that each installation maximizes energy savings effectively.

float glass

Industry authority is reflected in the rigorous standards float glass must meet. International benchmarks like ISO standards ensure that float glass products are tested for durability, clarity, and thermal performance. Manufacturers who adhere to these standards demonstrate commitment to quality,

instilling trust among architects, builders, and end-users alike.

For builders and developers, the trustworthiness of choosing float glass comes from its proven track record in diverse applications. Whether used in the dazzling façades of skyscrapers or the serene windows of a countryside home, float glass delivers consistent performance. Its adaptability to cutting and shaping allows it to meet bespoke design specifications, bridging aesthetic desires with practical needs.

Drawing from real-world experience, successful projects employing float glass often see a synergy between design intent and material utility. For instance, metro stations worldwide utilize float glass to create open, inviting spaces while ensuring commuter safety and comfort—a testament to its efficacy and reliability.

In conclusion, the expertise required to integrate float glass into modern designs cannot be understated. It serves as a bridge between aesthetic aspiration and practical application, backed by authoritative standards that guarantee quality and performance. As sustainability and energy efficiency become increasingly vital, float glass remains a premier choice, trusted for its durability and adaptability in ever-evolving architectural landscapes.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu