The Market Dynamics of 8% Toughened Glass Prices

Toughened glass, also known as tempered glass, has gained significant popularity in various industries due to its enhanced strength and safety features. Among the various specifications available in the market, 8% toughened glass has emerged as a prevalent choice for both residential and commercial applications. This article aims to delve into the factors influencing the pricing of 8% toughened glass, the demand-supply scenario, and its applications.

Understanding Toughened Glass

Toughened glass is produced by heating regular glass to a high temperature and then cooling it rapidly. This process increases its strength and makes it more resistant to thermal shock. Due to its safety features—breaking into small, blunt pieces rather than sharp shards—toughened glass is ideal for use in environments where safety is a concern, such as in buildings, vehicles, and furniture.

Factors Influencing Prices

1. Raw Material Costs The price of raw materials used in the production of toughened glass plays a crucial role in determining its market price. The key components include silica sand, soda ash, and limestone, the prices of which can fluctuate due to market demand and supply chain issues.

2. Manufacturing Process The complexity and technology involved in manufacturing 8% toughened glass also influence its production costs. Advanced machinery, skilled labor, and energy consumption during the heating and cooling process add to the overall costs, which are, in turn, reflected in the final pricing.

3. Regional Variations Prices for 8% toughened glass can vary significantly based on geographical locations. Factors such as local demand, transportation costs, and regional regulations can affect pricing structures. For example, areas with high construction activity may see increased prices due to higher demand.

4. Market Demand The demand for toughened glass has been steadily increasing, driven primarily by growth in the construction industry. The rise in residential and commercial building projects, as well as an increased focus on energy efficiency and sustainable materials, has led to a surge in the popularity of toughened glass, pushing prices higher.

5. Technology and Innovation Continuous advancements in glass manufacturing technology and the introduction of eco-friendly production methods can also impact pricing. Innovations that reduce production costs or improve quality may lead to more competitive pricing strategies among manufacturers.

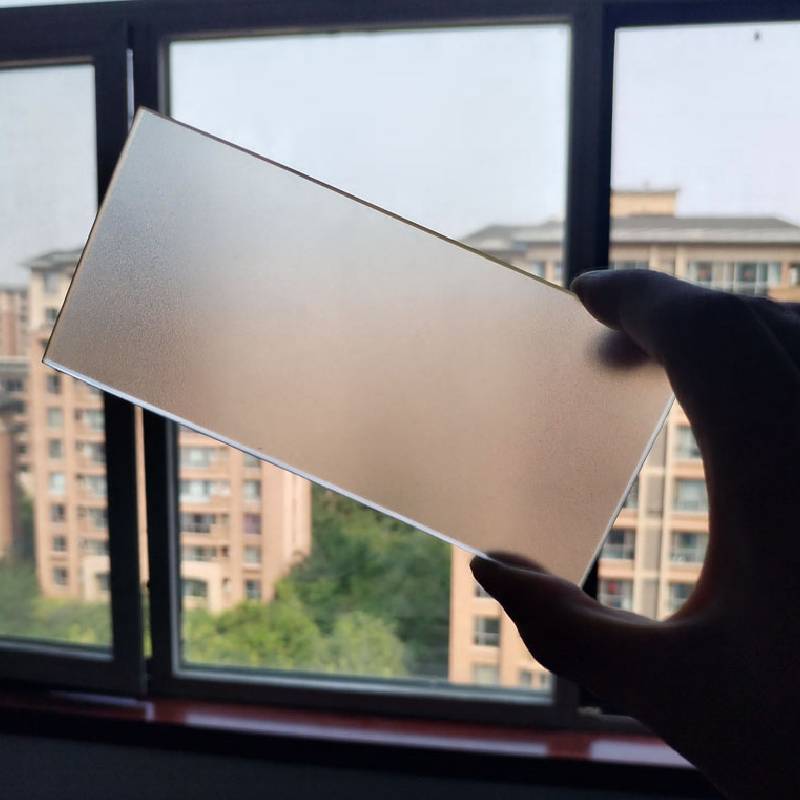

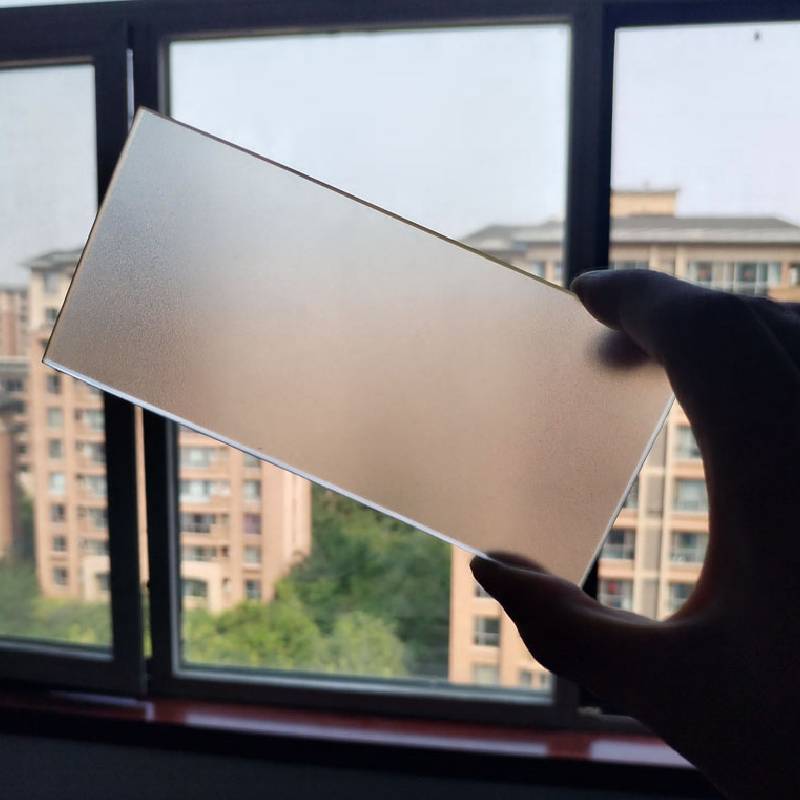

8 mm toughened glass price

Demand-Supply Scenario

The demand for 8% toughened glass remains robust across various sectors such as architecture, automotive, and furniture manufacturing. As urbanization continues to rise, there is an ever-increasing need for durable and safe building materials. Consequently, manufacturers are striving to meet this demand while managing production costs effectively.

In recent years, the construction industry has witnessed a shift towards using tougher and safer materials. More architects and builders are opting for toughened glass in their designs due to its aesthetic appeal and strength. This has tightened the supply chain, with manufacturers working to balance output to avoid shortages and overproduction, both of which can lead to price volatility.

Applications of 8% Toughened Glass

The versatility of 8% toughened glass makes it suitable for a wide array of applications. In residential settings, it is commonly used for shower enclosures, glass doors, and windows. The enhanced safety features make it a favored choice in homes with children or pets.

In commercial settings, 8% toughened glass is utilized in facades, storefronts, and partitions. Its modern appearance combined with safety and durability appeals to businesses aiming to create a contemporary aesthetic while ensuring the safety of customers and employees.

Moreover, the automotive industry employs toughened glass for windshields and side windows, where strength and shatter resistance are paramount.

Conclusion

The pricing of 8% toughened glass is influenced by a combination of material costs, manufacturing processes, demand, and technological advancements. As the sectors utilizing toughened glass continue to grow, understanding these dynamics becomes essential for stakeholders in the industry. Moving forward, manufacturers will need to adapt to changes in demand patterns and explore innovations to maintain competitive pricing while ensuring the safety and quality that customers expect from toughened glass products. The future of 8% toughened glass in the market looks promising, given its versatility and the continuing emphasis on safety and design.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu