The Impact of Float Glass on the Environment

The use of float glass in construction and automotive industries has significantly increased over the past few decades. This popularity is mainly due to its excellent optical properties, thermal insulation, and durability. However, the production of float glass also has a significant impact on the environment. In this article, we will discuss the environmental concerns associated with float glass production and explore ways to mitigate these effects.

One of the primary environmental concerns associated with float glass production is the high energy consumption involved in the process. The manufacturing of float glass requires a significant amount of electricity, which is primarily generated from fossil fuels. This leads to the emission of greenhouse gases, such as carbon dioxide, which contribute to global warming. Additionally, the high temperatures required for the production process can also lead to the release of other pollutants, such as nitrogen oxides and sulfur dioxide, which can have adverse effects on air quality.

Another environmental concern is the disposal of waste materials generated during the production of float glass. The process involves the use of raw materials, such as sand, soda ash, and limestone, which are converted into molten glass. During this process, some of the raw materials may not be fully utilized, resulting in the generation of waste materials During this process, some of the raw materials may not be fully utilized, resulting in the generation of waste materials

During this process, some of the raw materials may not be fully utilized, resulting in the generation of waste materials During this process, some of the raw materials may not be fully utilized, resulting in the generation of waste materials

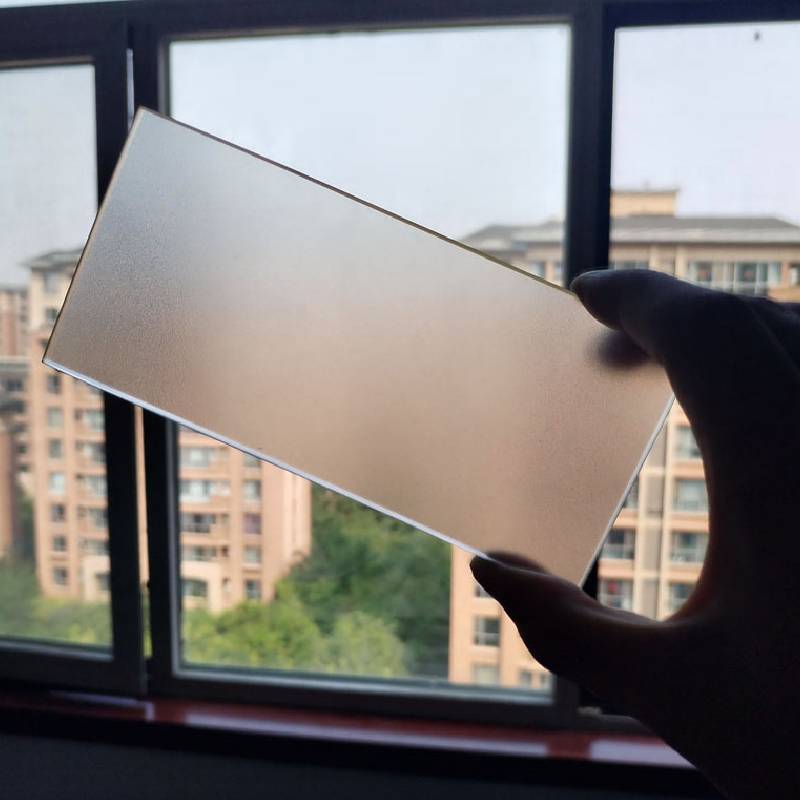

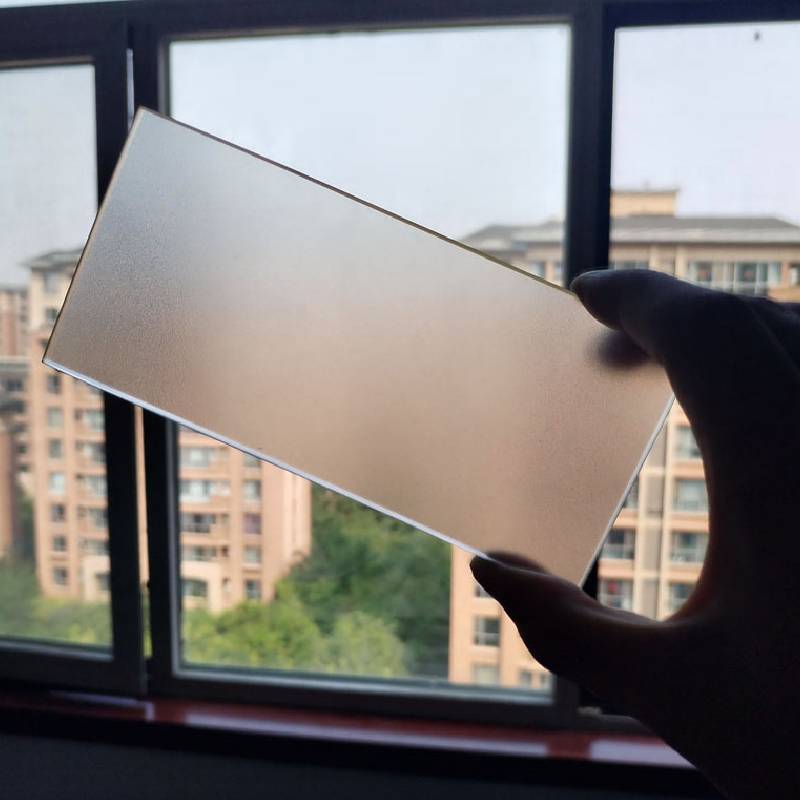

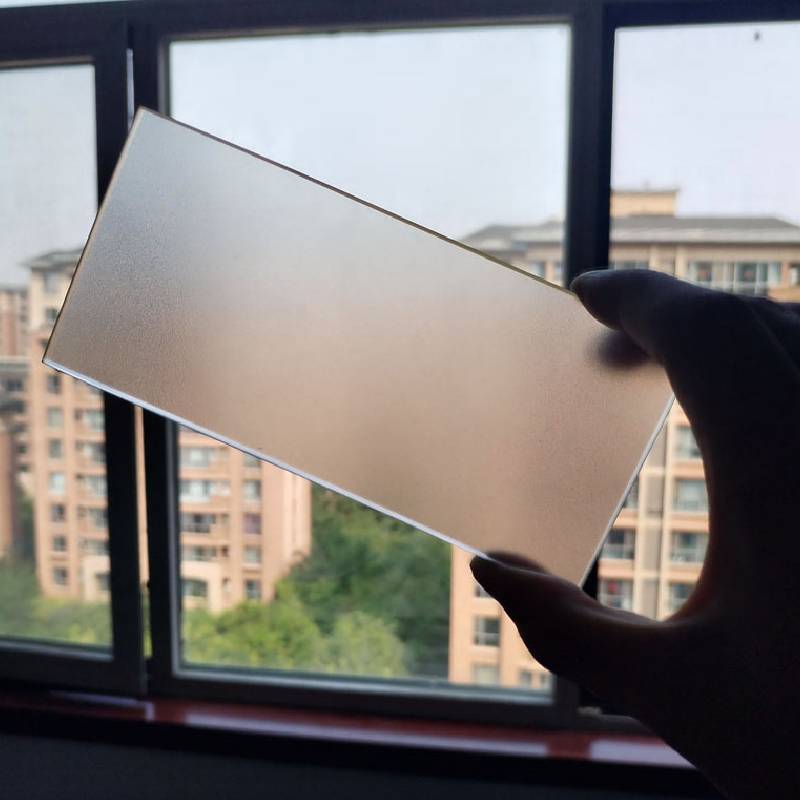

float glass uses

float glass uses. These waste materials can contain harmful substances, such as heavy metals and volatile organic compounds, which can pose a threat to the environment if not properly managed.

To mitigate the environmental impact of float glass production, several strategies can be employed. Firstly, the industry can invest in renewable energy sources, such as solar or wind power, to reduce its reliance on fossil fuels. This would not only decrease greenhouse gas emissions but also help to promote sustainable development. Secondly, the industry can adopt more efficient production techniques and equipment to reduce energy consumption and waste generation. For example, using heat recovery systems can help to recover heat from the production process and reduce the need for additional energy inputs. Finally, proper waste management practices, such as recycling and proper disposal, can help to minimize the environmental impact of waste materials generated during the production process.

In conclusion, while float glass has numerous benefits for construction and automotive industries, its production also has significant environmental impacts. By adopting sustainable practices and investing in renewable energy sources, the industry can help to mitigate these effects and promote a greener future.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

During this process, some of the raw materials may not be fully utilized, resulting in the generation of waste materials During this process, some of the raw materials may not be fully utilized, resulting in the generation of waste materials

During this process, some of the raw materials may not be fully utilized, resulting in the generation of waste materials During this process, some of the raw materials may not be fully utilized, resulting in the generation of waste materials