The Significance of Float Glass Factories in Modern Industry

Float glass, a fundamental material widely used in construction, automotive, and a variety of decorative applications, is produced through an innovative manufacturing process that has revolutionized the glass industry. The float glass factory, the heart of this production, plays a crucial role in meeting the growing demands for high-quality glass products in today's world.

The Float Glass Process

The float glass manufacturing process, developed in the mid-20th century, involves floating molten glass on a bed of molten tin. This method produces glass sheets that are remarkably flat and uniform in thickness. The process begins with the selection of raw materials silica sand, soda ash, and limestone, which are carefully mixed and melted at high temperatures, reaching around 1,600 degrees Celsius.

Once the glass is molten, it is introduced to the tin bath where it spreads out and forms a flat surface. The tin plays a significant role in the cooling process, allowing the glass to gain its desired smoothness and clarity. After floating, the glass is gradually cooled in a lehr, a controlled environment that minimizes internal stresses and ensures durability. Finally, the sheets are cut to size, packaged, and prepared for shipment to various industries.

Equipment and Technology

Modern float glass factories are equipped with advanced technology and machinery that enhance the efficiency and quality of production. Automation and computerization play vital roles in monitoring temperatures, chemical compositions, and the cutting processes. Robotic systems handle the glass sheets with precision, minimizing the risk of damage.

Environmental considerations are increasingly becoming a priority. Many float glass factories have implemented measures to reduce waste, recycle materials, and lower energy consumption. Advances in technology enable factories to utilize renewable energy sources, such as solar power, to operate their facilities more sustainably.

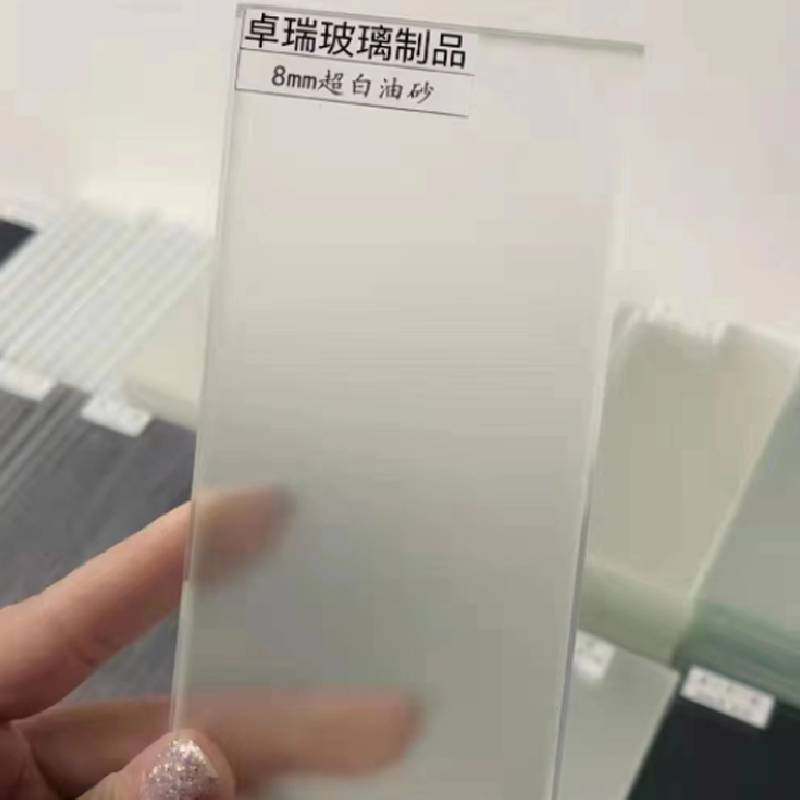

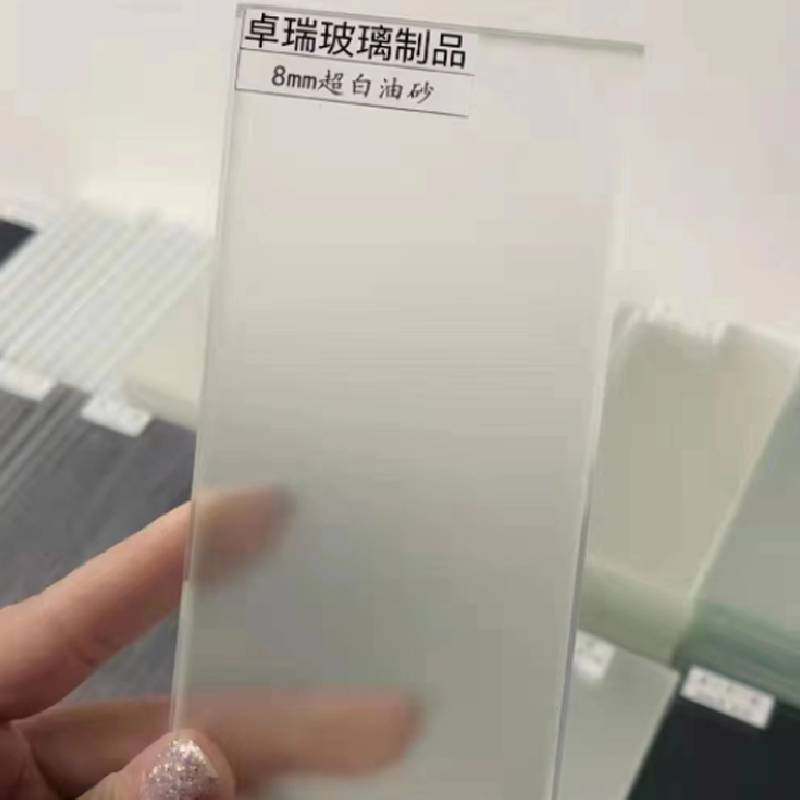

float glass factory

Applications of Float Glass

Float glass is indispensable in numerous applications. In the construction industry, it is used for windows, facades, and glass doors, allowing natural light to enter buildings while providing thermal insulation and security. In the automotive sector, float glass is employed for windshields and side windows, ensuring visibility and safety for drivers and passengers.

Moreover, float glass has found its way into decorative applications. Its aesthetic appeal and versatility make it suitable for mirrors, glass tables, and decorative panels. With advancements in coating technologies, float glass can also be modified to enhance properties such as solar control and low emissivity, further expanding its range of applications.

Economic Impact

The float glass industry significantly contributes to the global economy. As urbanization continues to rise, the demand for float glass is expected to grow, leading to job creation in manufacturing and associated sectors. Countries investing in infrastructure development require vast amounts of float glass, driving both local and international trade.

Additionally, float glass factories often collaborate with research institutions to innovate new products and improve existing ones. This synergy leads to the development of specialized glass types, such as self-cleaning glass or glass with enhanced thermal insulation, meeting specific market needs.

Conclusion

In conclusion, float glass factories are vital contributors to modern industry, providing essential materials that shape our built environment. The innovative processes employed in these factories not only produce high-quality glass but also reflect a commitment to sustainability and efficiency. As technology continues to evolve, the float glass industry is poised for growth, promising to meet the ever-increasing demand for glass in various applications. The future of float glass manufacturing is bright, with endless possibilities for innovation and improvement, making it an exciting field to watch in the years to come.

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu